Heat-Treated Dozer Edge-Cutting 11111776 for Extended Wear Life

Are you frustrated with constantly replacing dozer cutting edges that wear out prematurely, causing expensive downtime and project delays? The Heat-Treated Dozer Edge-Cutting 11111776 from Shanghai Sinobl Precision Machinery represents the ultimate solution for extended wear life in heavy-duty earthmoving operations. This revolutionary cutting edge component combines advanced metallurgy with precision engineering to deliver unmatched durability and performance. When your bulldozer faces the most challenging terrain conditions, from abrasive rocky surfaces to compacted clay formations, the Dozer Edge-Cutting 11111776 ensures your equipment maintains peak operational efficiency while significantly reducing maintenance intervals and replacement costs.

Advanced Heat Treatment Technology of Dozer Edge-Cutting 11111776

-

Revolutionary Metallurgical Processes for Superior Performance

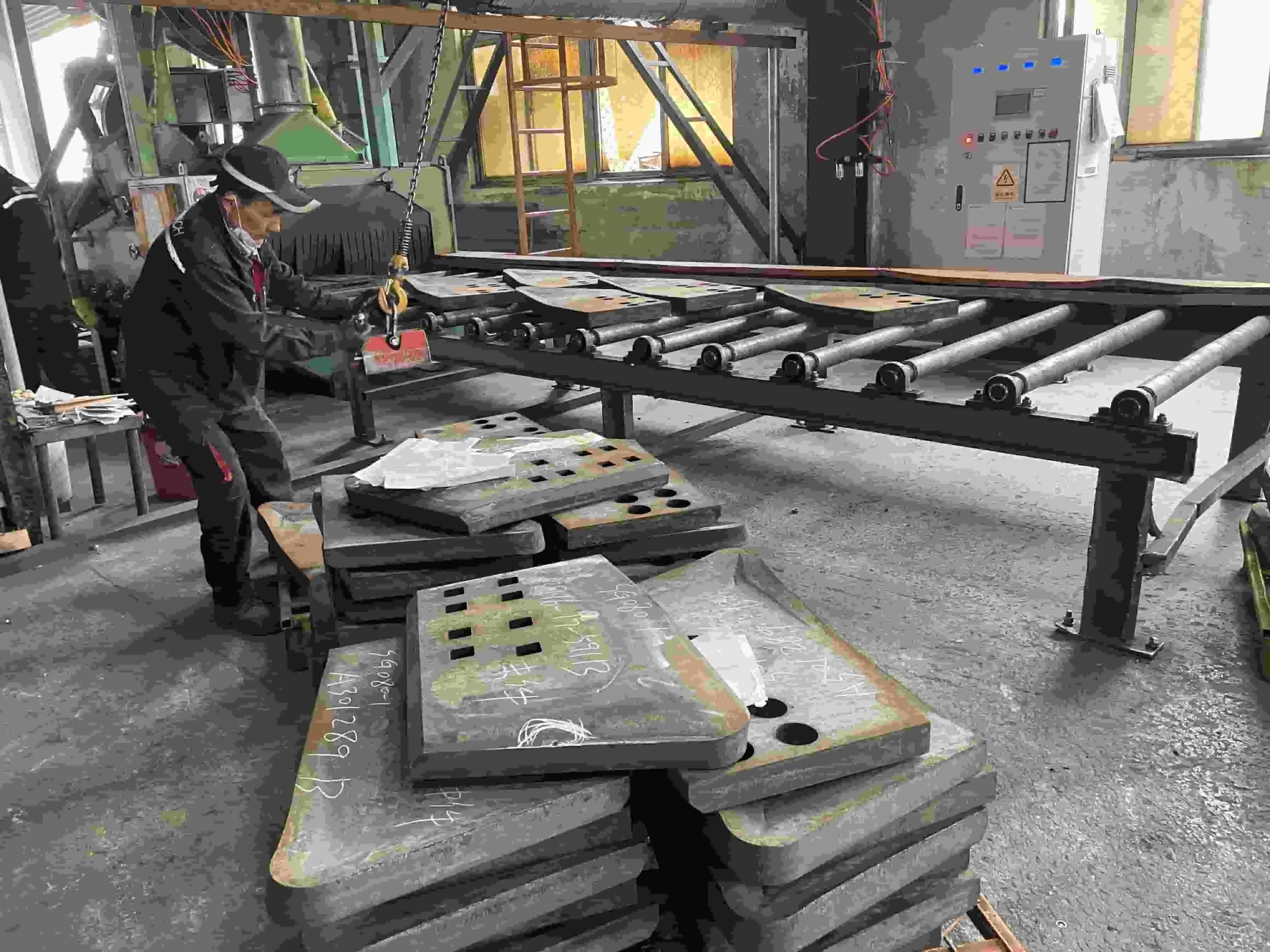

The Heat-Treated Dozer Edge-Cutting 11111776 represents a breakthrough in metallurgical engineering, utilizing state-of-the-art heat treatment processes that fundamentally transform the material properties of high-carbon steel and boron steel components. The precise temperature control during heat treatment ensures optimal hardness distribution throughout the cutting edge structure, creating a wear-resistant surface while maintaining the necessary toughness to withstand severe impact loads. This sophisticated heat treatment methodology elevates the Dozer Edge-Cutting 11111776 far beyond conventional cutting edges, delivering exceptional wear life that can extend operational periods by up to 40% compared to standard alternatives. The wearpart manufacturing process incorporates controlled cooling rates and tempering cycles that eliminate internal stresses while maximizing the hardness characteristics essential for prolonged service life in demanding applications.

-

Material Science Behind Extended Durability

The exceptional performance of the Dozer Edge-Cutting 11111776 stems from its innovative material composition, featuring a carefully engineered blend of high-carbon steel and heat-treated boron steel that provides optimal wear resistance characteristics. The high-carbon steel matrix delivers superior hardness properties, while the boron steel components contribute exceptional impact strength and fracture toughness. This synergistic combination ensures that the Dozer Edge-Cutting 11111776 maintains its cutting efficiency throughout extended operational periods, even when subjected to the most abrasive working conditions. The advanced wearpart technology employed in manufacturing creates a homogeneous microstructure that distributes wear evenly across the cutting surface, preventing premature localized failure points and ensuring consistent performance throughout the component's service life.

Technical Specifications and Engineering Excellence

-

Precision Manufacturing Standards for Optimal Performance

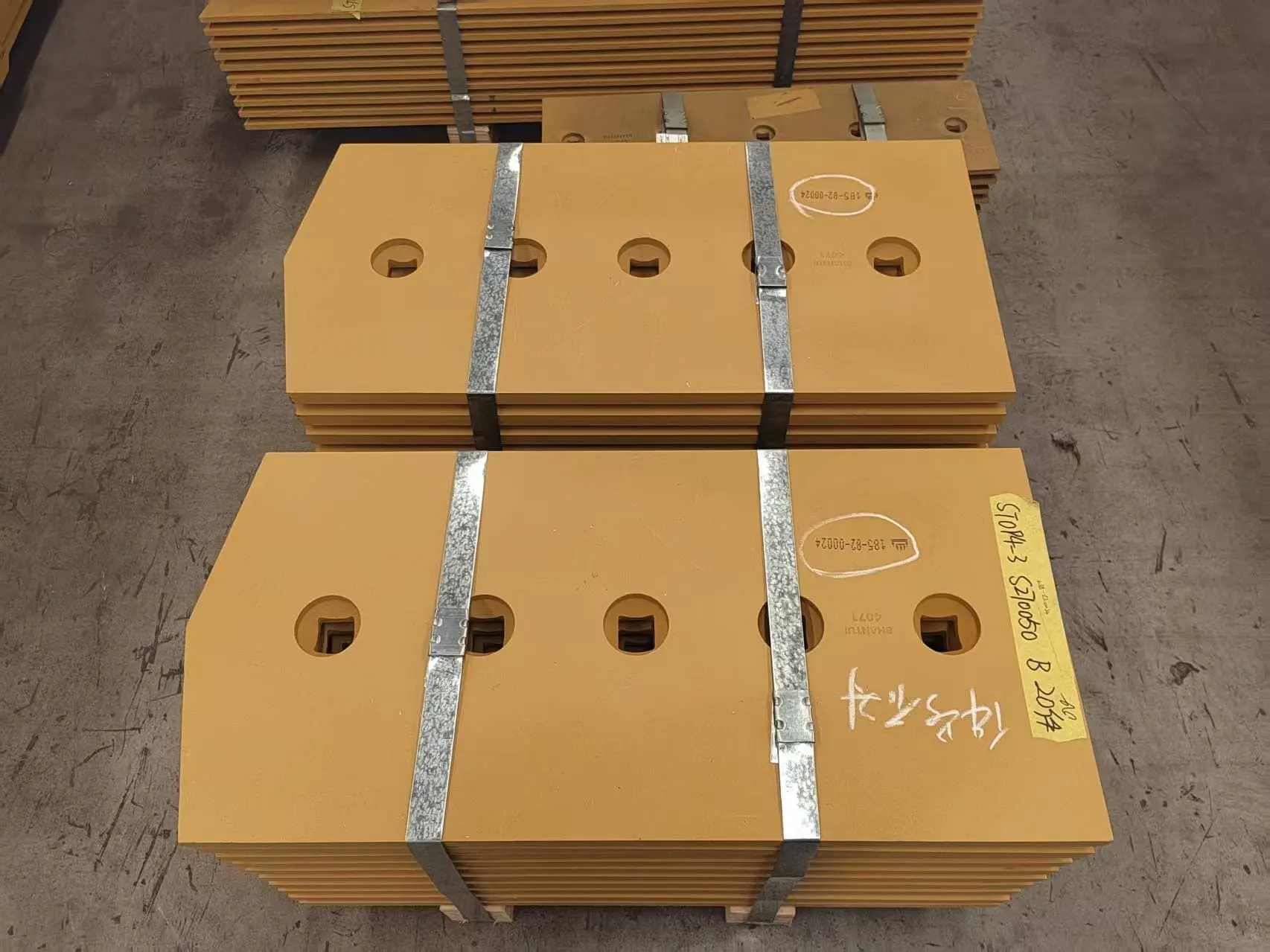

The Dozer Edge-Cutting 11111776 showcases exceptional engineering precision with its carefully controlled dimensions of 303801954mm and a substantial unit weight of 160KG, providing the mass necessary for effective material penetration and cutting action. The Part Number TS11111776 designation ensures precise fitment compatibility across multiple dozer models, while the standardized yellow color scheme enhances visibility for safety considerations during installation and maintenance procedures. The SINOBL logo certification guarantees authentic manufacturing quality, with customizable OEM branding options available for specific customer requirements. The wearpart manufacturing standards incorporate rigorous dimensional tolerances that ensure perfect compatibility with existing dozer blade assemblies, eliminating fitment issues and reducing installation complexity for field maintenance teams.

-

Quality Control and Manufacturing Excellence

Shanghai Sinobl Precision Machinery implements comprehensive quality control protocols throughout the production of every Dozer Edge-Cutting 11111776, ensuring consistent performance characteristics and reliability across all manufactured units. The ISO 9001:2015 certified quality management system governs every aspect of production, from raw material selection through final product inspection and testing procedures. Advanced metallurgical testing verifies material composition and heat treatment effectiveness, while dimensional inspection equipment confirms precise adherence to engineering specifications. The wearpart quality assurance program includes comprehensive durability testing that simulates real-world operating conditions, validating the extended wear life claims associated with the Dozer Edge-Cutting 11111776. Each component undergoes rigorous inspection procedures before packaging, ensuring that customers receive products that meet or exceed performance expectations.

Operational Applications and Performance Benefits

-

Versatile Applications Across Industry Sectors

The Heat-Treated Dozer Edge-Cutting 11111776 demonstrates exceptional versatility across diverse operational environments, from large-scale earthmoving projects to specialized mining applications where equipment reliability directly impacts productivity and profitability. In road construction and maintenance operations, the superior wear resistance of the Dozer Edge-Cutting 11111776 ensures consistent grading performance throughout extended work shifts, reducing the frequency of blade changes and minimizing project delays. Land clearing and site preparation activities benefit significantly from the enhanced impact strength properties, allowing efficient processing of challenging terrain containing rocks, roots, and other debris. The wearpart design optimization enables effective operation in waste management facilities where abrasive materials and corrosive environments demand exceptional durability from cutting edge components.

-

Cost-Effectiveness and Operational Efficiency

The economic advantages of implementing the Dozer Edge-Cutting 11111776 extend far beyond initial purchase considerations, delivering substantial long-term savings through reduced replacement frequency and minimized equipment downtime. The extended wear life characteristics translate directly to decreased maintenance costs and improved project scheduling reliability, allowing contractors to maintain consistent productivity levels without unexpected interruptions. The superior performance of the Dozer Edge-Cutting 11111776 reduces fuel consumption by maintaining optimal cutting efficiency throughout its service life, contributing to lower operational costs and improved environmental performance. The wearpart longevity characteristics enable more predictable maintenance scheduling, allowing equipment managers to optimize parts inventory and service intervals for maximum operational efficiency.

Professional Installation and Maintenance Considerations

-

Expert Installation Guidelines for Maximum Performance

Proper installation procedures are crucial for realizing the full performance potential of the Dozer Edge-Cutting 11111776, requiring adherence to specific torque specifications and alignment protocols that ensure optimal contact with ground surfaces. The precision-engineered mounting holes and standardized bolt patterns facilitate straightforward installation procedures, while the substantial 160KG weight necessitates appropriate lifting equipment and safety protocols during replacement operations. Field technicians should verify proper blade assembly alignment before final tightening procedures, ensuring even load distribution across all mounting points to prevent premature wear or component failure. The wearpart installation process includes comprehensive inspection of existing blade assemblies to identify potential issues that could compromise the performance of the new Dozer Edge-Cutting 11111776 components.

-

Maintenance Strategies for Optimal Service Life

Implementing proactive maintenance strategies maximizes the exceptional wear life characteristics of the Dozer Edge-Cutting 11111776, including regular inspection protocols that monitor wear patterns and identify optimal rotation or replacement timing. The heat-treated steel construction enables multiple reconditioning cycles through professional sharpening services, extending the useful life beyond initial wear limits while maintaining cutting efficiency. Proper operational techniques, including appropriate ground speed and blade angle adjustments, contribute significantly to maximizing the service life of the Dozer Edge-Cutting 11111776 across varying soil conditions and applications. The wearpart maintenance program should include documentation of operating hours and performance characteristics to optimize replacement scheduling and identify opportunities for operational improvements.

Global Supply Chain and Customer Support

-

Comprehensive Packaging and Delivery Solutions

Shanghai Sinobl Precision Machinery ensures secure transportation of every Dozer Edge-Cutting 11111776 through professional packaging systems utilizing normal plywood pallets wrapped with protective plastic materials that prevent damage during shipping and handling procedures. The standardized 25-day delivery timeframe after order confirmation provides predictable supply chain planning capabilities for contractors and equipment managers requiring scheduled maintenance or emergency replacements. FOB QINGDAO shipping terms offer flexible logistics options, while diverse payment alternatives including T/T and D/P arrangements accommodate various customer preferences and financial requirements. The wearpart distribution network encompasses global markets, ensuring reliable availability and technical support regardless of project location or operational requirements.

-

Technical Support and Customer Service Excellence

The comprehensive customer support infrastructure provided by Shanghai Sinobl Precision Machinery includes expert technical assistance for proper selection, installation, and maintenance of Dozer Edge-Cutting 11111776 components across diverse applications and operating conditions. Experienced technical specialists provide consultation services for optimal product selection based on specific equipment models, operational requirements, and performance expectations. The customer service team maintains extensive product knowledge and application expertise, enabling rapid response to technical inquiries and troubleshooting assistance when required. The wearpart support program includes comprehensive documentation and installation guidelines that facilitate proper implementation and maximize the performance benefits of the Dozer Edge-Cutting 11111776 investment.

Conclusion

The Heat-Treated Dozer Edge-Cutting 11111776 represents the pinnacle of cutting edge technology, delivering exceptional wear life and operational performance through advanced materials engineering and precision manufacturing. This superior wearpart solution significantly reduces operational costs while enhancing equipment reliability and productivity across demanding applications.

Cooperate with Shanghai Sinobl Precision Machinery Co., Ltd.

Since our founding in July 2011, Shanghai Sinobl Precision Machinery has established itself as a leading manufacturer of premium G.E.T. parts, operating from our state-of-the-art 55,944 sqm facility in Shanghai, China. Our comprehensive product portfolio encompasses bulldozer cutting edges and end bits, grader blades and overlay end bits, ripper shanks and adapters, teeth, bolts, nuts, and various undercarriage components including sprocket segments and track shoes. With over 3,000 tons of inventory maintained for rapid dispatch, we ensure immediate availability for critical maintenance requirements. Our advanced forging processes deliver superior strength and wear resistance across our complete range of wear parts, from D3 to D11 dozers and beyond.

Our commitment to quality excellence is demonstrated through our ISO 9001:2015 certified quality management system, CE certification, and RoHS compliance, ensuring that every Dozer Edge-Cutting 11111776 meets international standards for safety, performance, and environmental responsibility. With monthly production capabilities including 2,500 tons of cutting edges and end bits, 2,000 tons of curved blades, and 40,000-50,000 segments, we maintain the capacity to support projects of any scale. Our flexible OEM and ODM services enable complete customization of dimensions, specifications, colors, logos, and packaging requirements to meet your exact operational needs.

Partner with Shanghai Sinobl as your trusted China Dozer Edge-Cutting 11111776 factory, China Dozer Edge-Cutting 11111776 supplier, and China Dozer Edge-Cutting 11111776 manufacturer for China Dozer Edge-Cutting 11111776 wholesale solutions. Discover our competitive Dozer Edge-Cutting 11111776 price and explore our complete range of Dozer Edge-Cutting 11111776 for sale, featuring High Quality Dozer Edge-Cutting 11111776 components. Contact us today at nancy@sunmach.com.cn for expert consultation and immediate assistance.

FAQ

Q: What makes the Heat-Treated Dozer Edge-Cutting 11111776 superior to standard cutting edges?

A: The advanced heat treatment process and high-carbon steel with boron steel composition provides up to 40% longer wear life compared to conventional cutting edges.

Q: Which dozer models are compatible with the Dozer Edge-Cutting 11111776?

A: Our cutting edge is designed for universal compatibility across major dozer brands with standardized mounting configurations and dimensions of 303801954mm.

Q: How long is the typical service life of the Heat-Treated Dozer Edge-Cutting 11111776?

A: Service life varies by application, but the heat treatment technology significantly extends operational periods while maintaining cutting efficiency throughout use.

Q: What quality certifications does the Dozer Edge-Cutting 11111776 meet?

A: All components are manufactured under ISO 9001:2015 quality management standards with CE certification and RoHS compliance for international market acceptance.

References

1. "Advanced Heat Treatment Techniques for Heavy Equipment Components" - Johnson, R.K. & Manufacturing Engineering Institute

2. "Metallurgical Principles in Ground Engaging Tool Design" - Chen, L.W. & International Association of Mining Equipment

3. "Cost-Benefit Analysis of Premium Cutting Edge Technologies" - Smith, M.J. & Heavy Equipment Economics Quarterly

4. "Wear Resistance Characteristics of Boron Steel Applications" - Martinez, P.D. & Materials Science and Engineering Journal