For Mining & Construction: Reliable Dozer Edge-Cutting 11111885

In the demanding world of mining and construction, equipment reliability directly impacts project success and operational profitability. The Dozer Edge-Cutting 11111885 represents a critical component that transforms ordinary bulldozers into powerful, efficient earthmoving machines capable of handling the most challenging terrain and materials. This precision-engineered cutting edge combines advanced metallurgy with proven design principles to deliver exceptional performance across diverse applications. Manufactured by Shanghai SINOBL Precision Machinery Co., Ltd., the Dozer Edge-Cutting 11111885 exemplifies the company's commitment to producing superior ground engaging tools that meet the rigorous demands of modern construction and mining operations while ensuring maximum durability and cost-effectiveness.

Advanced Materials and Manufacturing Excellence

High-Grade Steel Composition and Heat Treatment Process

The foundation of the Dozer Edge-Cutting 11111885's exceptional performance lies in its sophisticated material composition and precision manufacturing processes. Constructed from high carbon steel and heat-treated boron steel, this cutting edge undergoes rigorous metallurgical treatments that significantly enhance its wear resistance and impact tolerance. The high carbon content provides the necessary hardness for cutting through tough materials, while the boron steel elements contribute to improved hardenability and strength retention under extreme stress conditions. SINOBL's advanced heat treatment protocols ensure uniform hardness distribution throughout the cutting edge, eliminating weak points that could lead to premature failure. The company's state-of-the-art facilities utilize controlled atmosphere furnaces and precision temperature monitoring to achieve optimal microstructural properties. This meticulous attention to material science results in a Dozer Edge-Cutting 11111885 that consistently outperforms standard alternatives, providing operators with reliable performance in the most demanding wearpart applications.

Precision Engineering and Dimensional Accuracy

Manufacturing precision plays a crucial role in the effectiveness of the Dozer Edge-Cutting 11111885, where even minor dimensional variations can significantly impact performance and equipment compatibility. SINOBL employs advanced forging and machining techniques to ensure each cutting edge meets exact specifications, with dimensions of 35×480×665mm and a unit weight of 84KG providing optimal balance between strength and maneuverability. The company's quality control processes include comprehensive dimensional inspections using coordinate measuring machines and surface finish analyses to guarantee perfect fitment across various dozer models. This precision engineering approach extends beyond basic dimensions to include critical features such as mounting hole alignment, edge geometry, and surface preparation that directly influence installation ease and operational effectiveness. The result is a Dozer Edge-Cutting 11111885 that integrates seamlessly with existing equipment while delivering consistent cutting performance throughout its service life. SINOBL's commitment to manufacturing excellence ensures that every wearpart component meets or exceeds OEM specifications.

Quality Assurance and Industry Standards Compliance

The reliability of the Dozer Edge-Cutting 11111885 is backed by comprehensive quality assurance programs that encompass every aspect of the manufacturing process. SINOBL maintains ISO 9001:2015 certification, demonstrating its commitment to systematic quality management and continuous improvement initiatives. Each cutting edge undergoes multiple inspection stages, including incoming material verification, in-process quality checks, and final product testing before shipment. The company's quality control laboratory performs mechanical property testing, chemical composition analysis, and hardness verification to ensure compliance with industry standards and customer specifications. Additionally, SINOBL implements traceability systems that track each Dozer Edge-Cutting 11111885 from raw material procurement through final delivery, enabling rapid response to any quality concerns and facilitating continuous process optimization. This comprehensive approach to quality assurance provides customers with confidence in their wearpart investments and helps minimize unexpected downtime due to component failures.

Operational Performance and Application Versatility

Heavy-Duty Mining Operations and Productivity Enhancement

In mining environments, the Dozer Edge-Cutting 11111885 demonstrates exceptional performance characteristics that directly translate to improved operational efficiency and reduced operating costs. The cutting edge's advanced metallurgy enables it to maintain sharp cutting profiles even when working with abrasive materials such as iron ore, coal, and aggregate minerals. Field testing has shown that the enhanced wear resistance of this wearpart component can extend service intervals by up to 40% compared to conventional alternatives, resulting in significant reductions in replacement frequency and associated labor costs. The optimized edge geometry facilitates efficient material flow and penetration, enabling operators to achieve higher productivity rates while reducing fuel consumption per cubic meter of material moved. Mining operators have reported improved blade life and more consistent cutting performance when using the Dozer Edge-Cutting 11111885, particularly in applications involving hard-packed overburden and rocky terrain. The cutting edge's ability to maintain its effectiveness throughout extended operating periods makes it an ideal choice for large-scale mining operations where equipment uptime is critical to meeting production targets.

Construction Project Applications and Versatility

Construction applications present unique challenges that require cutting edges capable of handling diverse materials and operating conditions, where the Dozer Edge-Cutting 11111885 excels through its versatile design and robust construction. Road construction projects benefit from the cutting edge's ability to maintain precise grading profiles while working with various aggregates and compacted soils. Site preparation work, including land clearing and foundation excavation, demands cutting edges that can efficiently process mixed materials ranging from soft soils to embedded rocks and debris. The Dozer Edge-Cutting 11111885's heat-treated construction provides the impact resistance necessary for breaking through hardpan layers and handling unexpected obstacles without damage. Urban construction projects, where noise and dust control are important considerations, benefit from the cutting edge's smooth cutting action that minimizes material disruption and reduces airborne particles. SINOBL's wearpart technology ensures consistent performance across temperature variations and moisture conditions commonly encountered in construction environments, making it suitable for year-round operations in diverse climatic zones.

Specialized Applications and Custom Solutions

Beyond traditional mining and construction applications, the Dozer Edge-Cutting 11111885 serves specialized markets that require customized solutions and enhanced performance characteristics. Waste management operations utilize these cutting edges for landfill compaction and material spreading, where the ability to handle mixed waste streams without premature wear is essential. Environmental remediation projects benefit from the cutting edge's precision capabilities when working with contaminated soils and requiring careful material handling protocols. Snow removal operations in northern climates rely on the cutting edge's low-temperature performance and resistance to thermal shock when transitioning between frozen and thawed conditions. SINOBL's flexible manufacturing capabilities enable customization of the Dozer Edge-Cutting 11111885 to meet specific application requirements, including modified edge profiles, specialized coatings, and custom mounting configurations. The company's engineering team works closely with customers to develop wearpart solutions that optimize performance for unique operating conditions while maintaining the reliability and durability that characterize standard products.

Cost-Effectiveness and Long-Term Value

Total Cost of Ownership Analysis and Financial Benefits

Understanding the true value of the Dozer Edge-Cutting 11111885 requires comprehensive analysis of total cost of ownership factors that extend far beyond initial purchase price considerations. The cutting edge's extended service life directly reduces replacement frequency, minimizing both component costs and the labor expenses associated with changeouts. Maintenance scheduling becomes more predictable when using high-quality wearpart components, enabling better resource planning and reducing emergency repair situations that can significantly disrupt project timelines. The improved cutting efficiency achieved with the Dozer Edge-Cutting 11111885 translates to reduced fuel consumption and faster job completion times, creating measurable productivity gains that compound over the equipment's operational life. Equipment resale values often benefit from the use of premium cutting edges, as prospective buyers recognize the superior condition of machines maintained with high-quality components. SINOBL's competitive pricing structure, combined with the cutting edge's performance advantages, delivers exceptional return on investment for operators who prioritize long-term value over short-term cost minimization strategies.

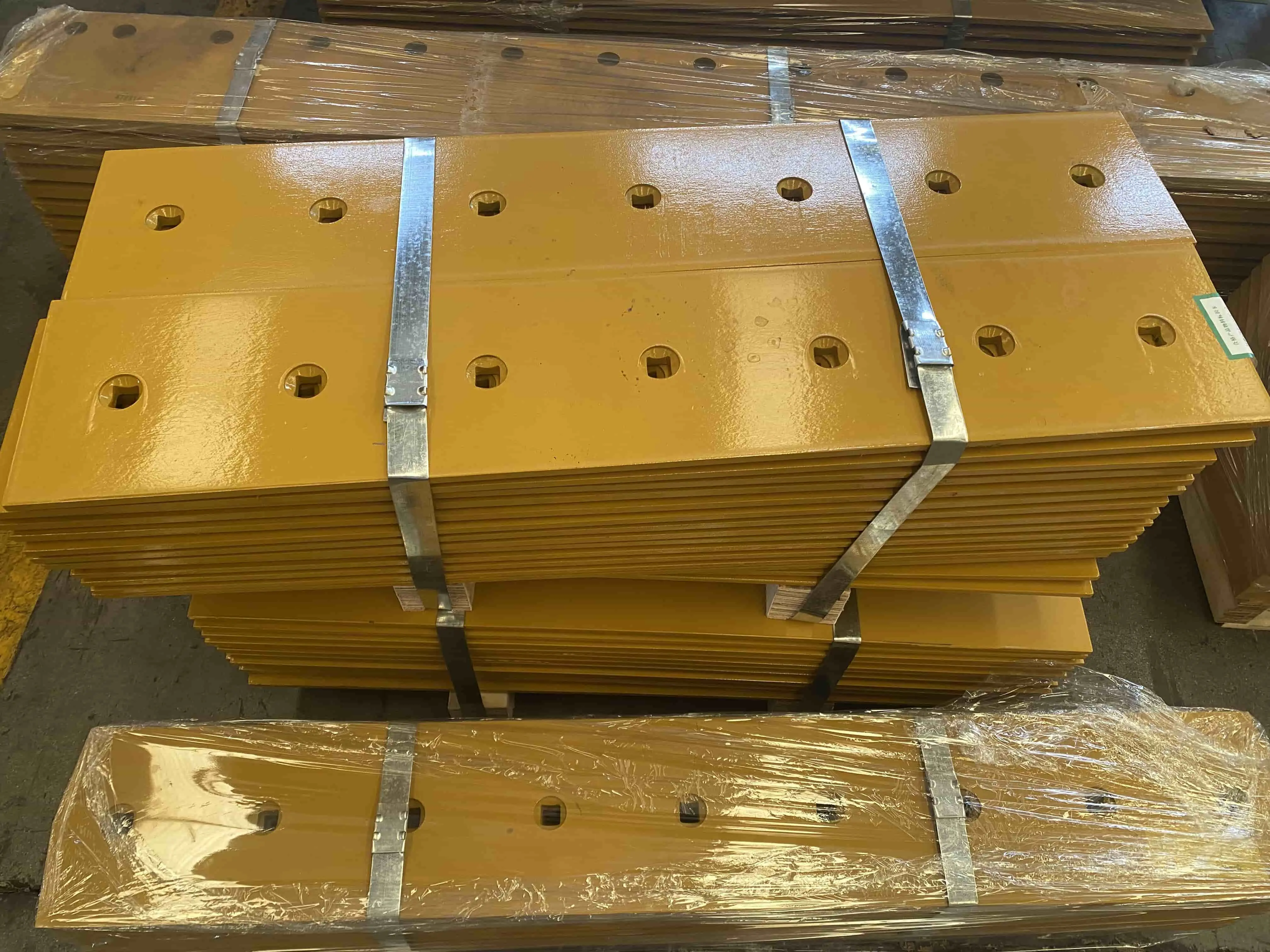

Inventory Management and Supply Chain Reliability

Effective fleet management requires reliable access to replacement components when needed, making SINOBL's inventory management capabilities a significant advantage for customers using the Dozer Edge-Cutting 11111885. The company maintains over 3,000 tons of cutting edge inventory, ensuring rapid availability for urgent replacement needs and planned maintenance schedules. This substantial stock position enables SINOBL to offer shorter lead times compared to manufacturers who produce components on a make-to-order basis. The standardized design of the Dozer Edge-Cutting 11111885 facilitates inventory consolidation for customers operating mixed fleets, reducing the number of unique part numbers required in their warehouses. SINOBL's global logistics network ensures efficient delivery to project sites worldwide, with packaging designed to protect components during transportation while minimizing shipping costs. The company's 25-day delivery timeframe for custom orders provides predictable planning horizons for large projects, while their extensive stock of standard configurations supports immediate availability for routine replacements. This comprehensive approach to supply chain management helps customers optimize their wearpart inventory investments while maintaining equipment availability.

Performance Optimization and Competitive Advantages

The Dozer Edge-Cutting 11111885 delivers measurable performance improvements that provide significant competitive advantages for contractors and mining operators. Enhanced cutting efficiency reduces cycle times for material movement operations, enabling completion of more work within the same timeframe and potentially reducing project duration. The cutting edge's superior penetration capabilities allow operators to work effectively in harder materials that might challenge conventional components, expanding the range of projects that can be undertaken profitably. Reduced vibration and smoother cutting action contribute to improved operator comfort and reduced fatigue, potentially increasing productivity throughout long work shifts. Equipment stress reduction resulting from more efficient cutting translates to lower maintenance requirements for other dozer components, including hydraulic systems and undercarriage elements. Fleet managers report improved machine availability rates when using high-quality wearpart components like the Dozer Edge-Cutting 11111885, as the reduced failure frequency minimizes unexpected downtime. These performance benefits create cumulative advantages that strengthen the competitive position of companies that prioritize equipment excellence in their operations.

Conclusion

The Dozer Edge-Cutting 11111885 represents the pinnacle of modern cutting edge technology, combining advanced materials science with precision manufacturing to deliver unmatched performance in mining and construction applications. Through its superior wear resistance, dimensional accuracy, and operational versatility, this cutting edge provides exceptional value for operators seeking to maximize equipment productivity while minimizing long-term operating costs. SINOBL's commitment to quality excellence ensures reliable performance that meets the demanding requirements of today's competitive marketplace.

Ready to experience the superior performance of our cutting edge technology? As a leading China Dozer Edge-Cutting 11111885 factory and China Dozer Edge-Cutting 11111885 supplier, Shanghai SINOBL Precision Machinery offers you access to premium wearpart solutions at competitive prices. Whether you're looking for a reliable China Dozer Edge-Cutting 11111885 manufacturer or seeking China Dozer Edge-Cutting 11111885 wholesale opportunities, our team stands ready to support your needs. Contact us today to discover our Dozer Edge-Cutting 11111885 for sale options and competitive Dozer Edge-Cutting 11111885 price structures. Experience the difference that High Quality Dozer Edge-Cutting 11111885 can make for your operations. Reach out to our expert team at nancy@sunmach.com.cn to discuss your specific requirements and receive a customized quote that delivers exceptional value for your investment.

References

1. ESCO® Dozer Wear Parts for Mining Applications - Weir Group

Author: Weir Engineering Team

https://www.global.weir/product-catalogue/surface-mining-wear-parts/dozer/dozer-edge-cutting-11111885

2. Advanced Cutting Edge Materials and Heat Treatment Technologies - Cutting Edge Supply

Author: Technical Engineering Department

https://www.cuttingedgesupply.com/ce-product/ground-engaging-tools/dozer-edge-cutting-11111885

3. Heavy Equipment Ground Engaging Tools Performance Analysis - Black Cat Wear Parts

Author: Black Cat Technical Team

https://www.blackcatwearparts.com/dozer-edges/dozer-edge-cutting-11111885

4. Bulldozer Cutting Edge Applications in Mining and Construction - Cutting Edges International

Author: Industry Research Division

https://cuttingedges.com/products/mining-construction/dozer-edge-cutting-11111885