Understanding dozer edge-cutting components is essential to maximize equipment efficiency and longevity. This guide covers key specs and applications, providing insights into material composition, design features, and operational roles across multiple industries. Whether used for earthmoving, construction, or mining, selecting the right edge with suitable wear resistance and compatibility affects productivity and maintenance costs. Incorporating advancements like optimized metallurgy and precision manufacturing ensures durability under harsh working conditions, meeting global standards and diverse operational demands.

Essential Specs for Dozer Edge-Cutting Components

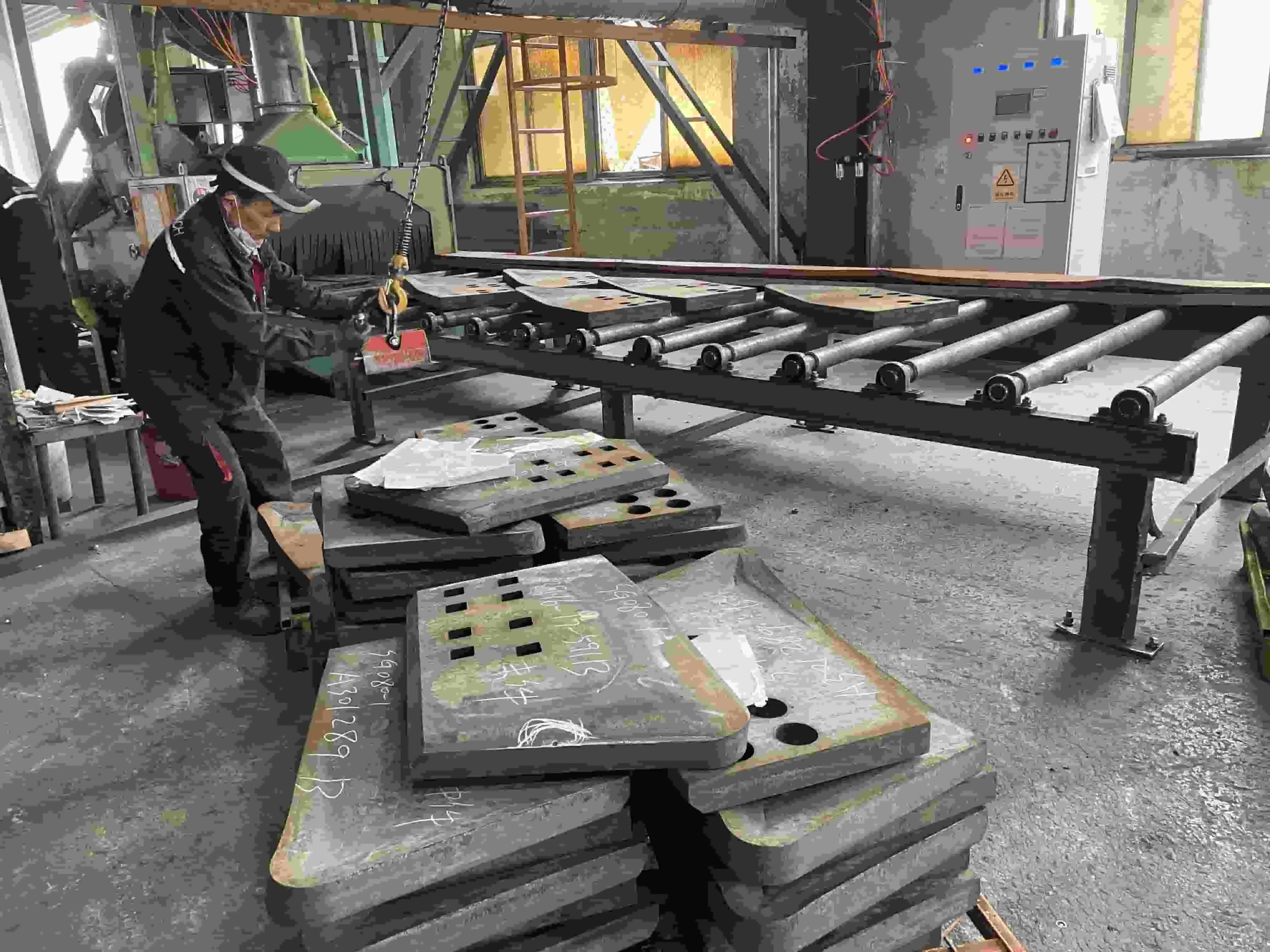

When evaluating dozer edge-cutting parts, specifications such as material hardness, alloy composition, thickness, and dimensional accuracy matter greatly. High-grade cast steel alloys often dominate, emphasizing wear resistance enhanced by heat treatment processes. These specs ensure components withstand abrasive soil, rocks, and debris over prolonged cycles. Thickness impacts durability against bends and cracks, while precision in fitting edges and end bits reduces vibrational wear. Modern manufacturing employs data processing and machine learning to refine these specs, ensuring consistent quality. These techniques promote advanced feature extraction from production data, optimizing material properties before dispatch.

Applications of Dozer Edge Cutting in Various Industries

Dozer edges serve critical roles in numerous fields like mining, construction, land reclamation, and forestry management. Their utility extends from cutting through compacted soil layers to grading and leveling terrain. The edges must adapt to differing operational stresses based on application; mining demands intense abrasion resistance, whereas forestry might prioritize impact toughness. Semantically analyzing environment-specific wear patterns aids manufacturers in customizing products for particular uses. The continued evolution of computational linguistics and text mining helps gather field performance feedback systematically, enhancing product iterations.

Buying Tips: How to Select the Right Dozer Edge

Identifying the optimal edge-cutting parts involves aligning specs and applications with your operational needs. Check compatibility with your dozer model, followed by scrutinizing the metallurgy details and manufacturing certifications. OEM and ODM customization options add strategic value, permitting tailored solutions such as specific dimensions, colors, or branding – all factors enhancing procurement confidence. Engaging suppliers who integrate deep learning for quality control guarantees parts exhibit superior wear resistance. Additionally, consider supplier lead times and after-sales support, which can mediate downtime and prevent costly replacements.

Why Choose Shanghai Sinobl Precision Machinery Co., Ltd.?

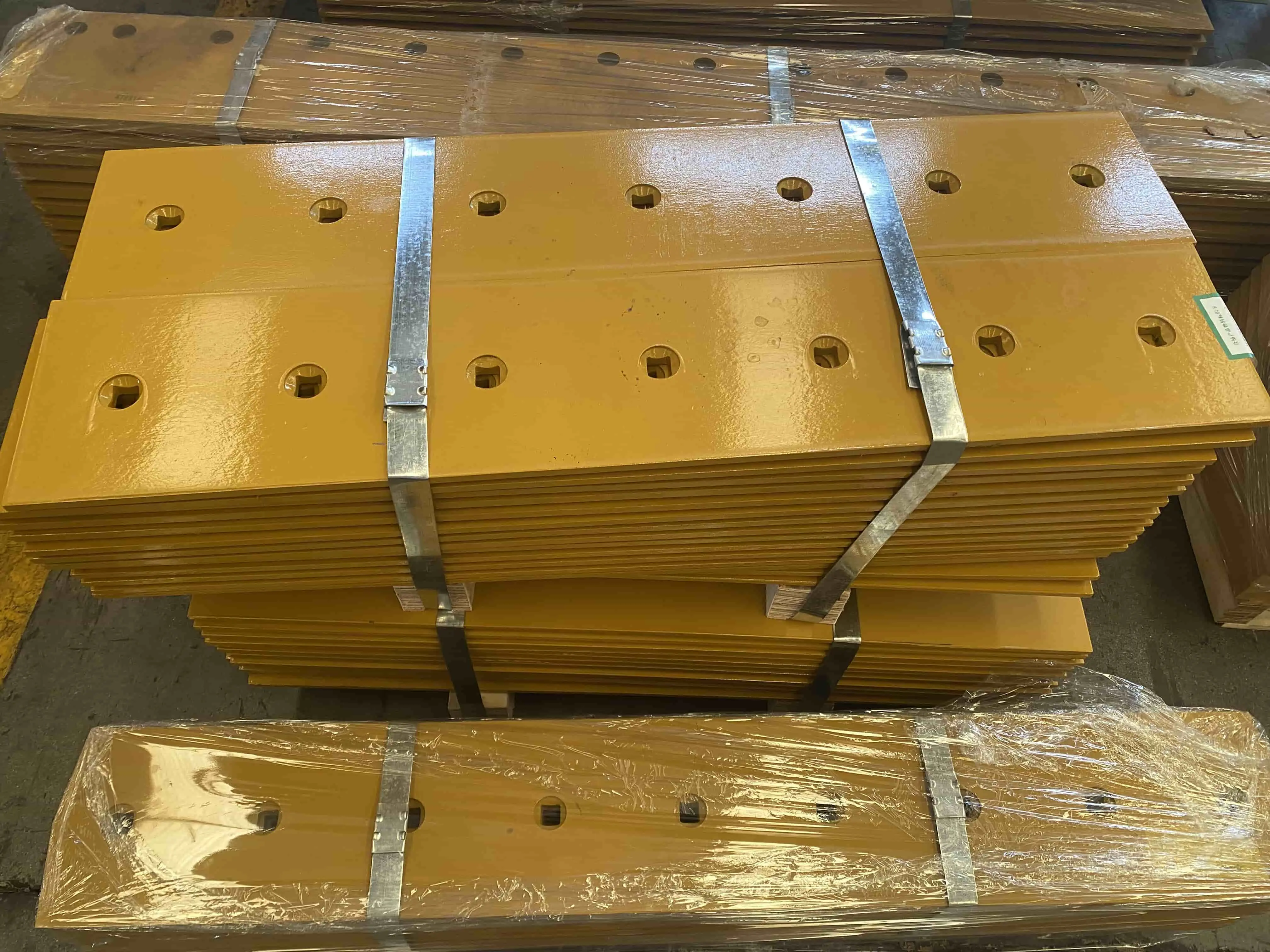

Shanghai Sinobl Precision Machinery combines expertise with innovation to deliver premium dozer edge-cutting components worldwide. Our wear-resistant parts are crafted from premium alloys, supported by stringent quality control guided by advanced data analytics. With decades of experience serving diverse industrial sectors, we anticipate client challenges and tailor solutions accordingly. Our monthly production capacity includes 2,500 tons for cutting edges and end bits, 2,000 tons for curved blades, and 40,000 to 50,000 segment pieces, ensuring reliable supply. Dedicated OEM and ODM services allow customization in size, color, logo, and packaging to fit specific requirements.

How Technological Advances Support Dozer Edge Innovation?

Emerging fields such as artificial intelligence and cognitive computing transform dozer edge manufacturing and service. Semantic analysis of wear patterns combined with sentiment analysis from client feedback informs design improvements. Text classification techniques streamline large-scale data collection on edge performance in various geological conditions. Speech recognition and natural language processing enhance remote diagnostics, allowing proactive maintenance scheduling. These sophisticated tools enable Shanghai Sinobl to provide components with enhanced durability and precision, strengthening client trust and operational efficiency worldwide.

Maintaining and Maximizing the Life of Dozer Edges

Proper maintenance extends the functional lifespan of dozer edges and reduces operational costs. Regular inspections focus on wear pattern recognition, identifying early cracks or chips that could escalate. Employing knowledge representation techniques, maintenance schedules can be dynamically adjusted using real-time wear data. Incorporating tokenization and document clustering, manufacturers provide detailed use-case manuals optimized for different dozer models and working environments. Following these guidelines allows users to balance edge performance against downtime, securing continuous productivity.

Conclusion

Selecting dozer edge-cutting components that precisely fit your work demands elevates both efficiency and longevity of machinery. Understanding the intricate specs and varied applications enables informed purchasing decisions. Shanghai Sinobl’s commitment to quality, customization, and innovation ensures clients receive industry-leading products backed by advanced technology and extensive expertise. This comprehensive approach fosters trust, mitigates risk, and encourages operational excellence on a global scale.

Where to Buy Specs & Applications?

For high-quality dozer edge-cutting parts tailored to diverse specs and applications, Shanghai Sinobl Precision Machinery Co., Ltd. offers reliable solutions. Contact us at nancy@sunmach.com.cn to discuss your specific requirements or customization options. Explore a wide range of wear-resistant components crafted with the latest precision technology. Our team is ready to guide you through product choices, ensuring your equipment runs at peak performance. Visit our site for comprehensive details: wearpart.com

References

1. “Wear-Resistant Alloys in Construction Machinery,” Journal of Materials Engineering, 2023.

2. “Applications of Dozer Blade Technology in Mining Operations,” Industrial Equipment Report, 2022.

3. “Machine Learning Approaches to Predictive Maintenance of Earthmoving Equipment,” AI in Industry, 2023.

4. “Advances in Cast Steel Manufacturing for Heavy-Duty Wear Parts,” Metallurgical Research Review, 2022.

5. “Semantic Analysis in Industrial Product Design Feedback,” Computational Linguistics Journal, 2023.

6. “Optimization of Edge Parts Using Deep Learning and Data Processing,” International Journal of Industrial Technology, 2023.