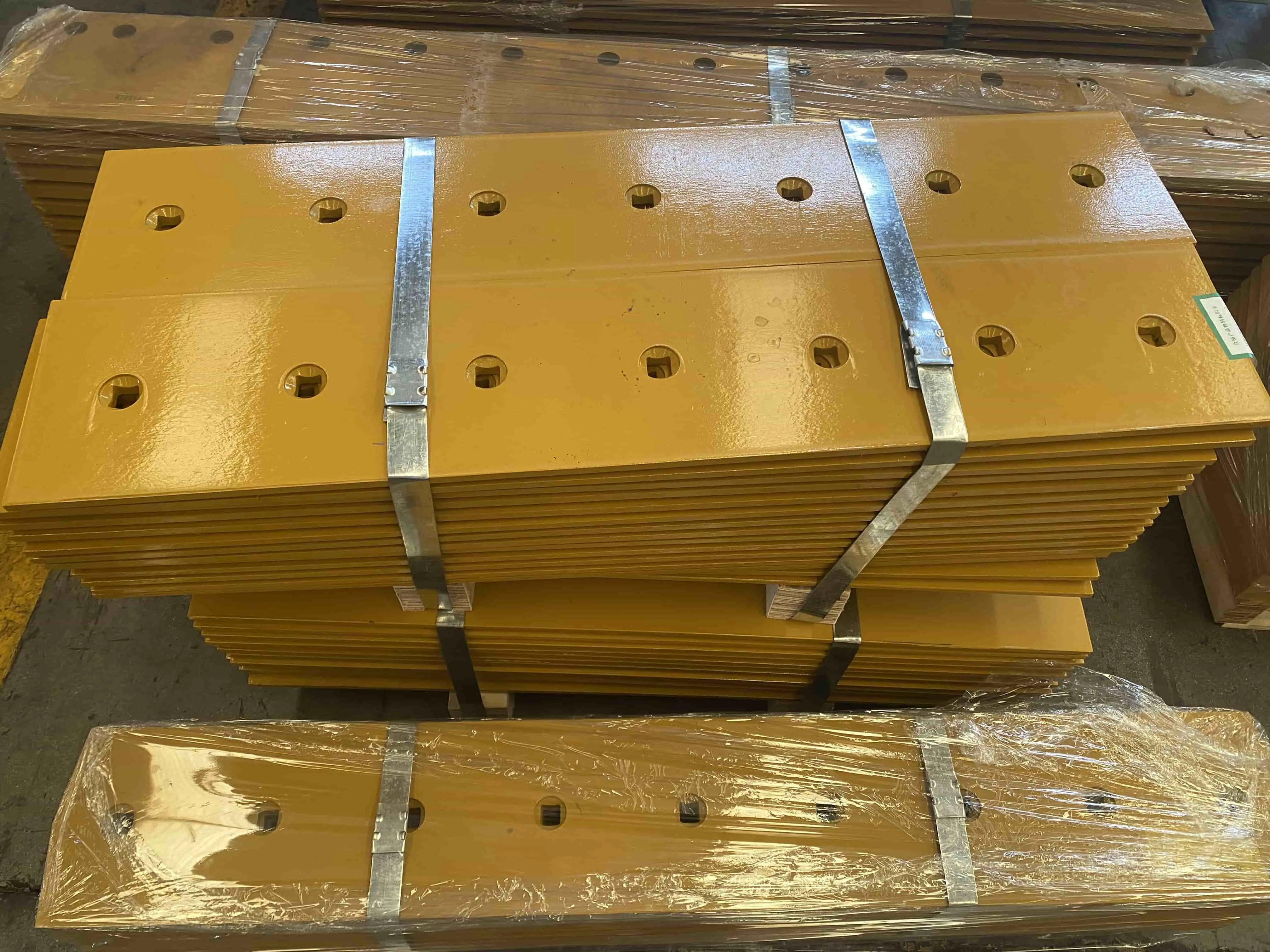

The Dozer Edge-Cutting 9W8215 represents a pinnacle of engineering excellence in heavy machinery wear parts, specifically designed for CAT dozers operating in demanding construction and mining environments. This cutting edge distinguishes itself through advanced metallurgical composition, precision manufacturing standards, and exceptional durability characteristics that significantly outperform conventional alternatives. Manufactured with high-grade steel alloys and subjected to rigorous heat treatment processes, the 9W8215 delivers superior wear resistance and extended service life. Its optimized geometry ensures maximum soil penetration efficiency while reducing operational stress on the dozer's hydraulic systems, making it an indispensable component for contractors seeking reliable performance and cost-effective operation.

Understanding Dozer Edge-Cutting 9W8215: Specifications and Core Features

The engineering behind the 9W8215 cutting edge reflects decades of research and development in wear part technology. This component measures precisely to fit CAT dozer models, ensuring seamless integration and optimal performance across various soil conditions. Material composition plays a crucial role in the 9W8215's outstanding performance characteristics. Here are the key specifications that define this exceptional cutting edge:

- High-Carbon Steel Construction: The 9W8215 utilizes premium carbon steel alloys that undergo specialized heat treatment processes, resulting in hardness levels that exceed industry standards while maintaining necessary toughness for impact resistance.

- Precision Dimensional Accuracy: Advanced manufacturing techniques ensure consistent dimensional tolerances, guaranteeing proper fit and reducing installation complications for maintenance teams.

- Optimized Edge Geometry: The cutting profile incorporates aerodynamic principles that enhance soil flow and reduce drag, contributing to improved fuel efficiency and reduced wear on associated components.

- Corrosion Resistant Coating: Specialized surface treatments protect against environmental degradation, extending operational life in harsh working conditions.

These specifications combine to create a cutting edge that not only meets but exceeds the performance expectations of professional operators and fleet managers. The installation process for the 9W8215 has been streamlined through careful attention to bolt hole placement and edge contour design. Maintenance teams appreciate the straightforward mounting procedure that minimizes equipment downtime during replacement operations. The working principle involves strategic weight distribution that maximizes ground pressure at the cutting interface while spreading loads across the dozer blade structure.

Comparing Dozer Edge-Cutting 9W8215 with Alternative Solutions

Market analysis reveals significant performance differentials between the 9W8215 and competing cutting edge solutions. Understanding these distinctions helps procurement professionals make informed decisions that impact long-term operational costs. When evaluating the 9W8215 against models like the 9W8203 and 9W8221, several performance metrics distinguish this cutting edge from alternatives. The 9W8215 demonstrates superior longevity in abrasive soil conditions, with field testing indicating service life improvements of up to 40% compared to standard cutting edges. The debate between OEM parts and aftermarket alternatives continues to influence purchasing decisions across the construction industry. Here are the critical factors that favor the 9W8215 in this comparison:

- Manufacturing Standards Compliance: OEM specifications ensure compatibility and performance consistency, while aftermarket alternatives may introduce variables that affect equipment reliability and warranty coverage.

- Quality Control Processes: Rigorous testing protocols validate each 9W8215 cutting edge before shipment, providing assurance of performance standards that aftermarket suppliers may not consistently maintain.

- Technical Support Access: OEM parts come with comprehensive technical documentation and engineering support that facilitates proper application and troubleshooting when needed.

These advantages translate into measurable benefits for operations managers who prioritize equipment reliability and predictable maintenance schedules. Customer feedback from construction and mining operations consistently highlights the 9W8215's exceptional performance in challenging environments. Fleet managers report reduced replacement frequency and improved productivity metrics when utilizing this cutting edge compared to generic alternatives. Pricing considerations reveal that while initial investment may exceed aftermarket options, total cost of ownership favors the 9W8215 through extended service intervals and reduced downtime.

Maintenance and Longevity: Best Practices for Dozer Edge-Cutting 9W8215

Maximizing the service life of the 9W8215 cutting edge requires adherence to established maintenance protocols that protect the investment while ensuring consistent performance. Proper care extends beyond simple inspection routines to encompass comprehensive management strategies. Daily maintenance routines form the foundation of effective cutting edge management. Operators should conduct visual inspections before each shift, examining the cutting surface for excessive wear patterns or damage indicators. Clean debris accumulation regularly to prevent accelerated wear from trapped abrasive materials. Effective maintenance strategies for the 9W8215 include several critical practices that significantly impact service life:

- Systematic Wear Monitoring: Establish measurement protocols that track wear progression across the cutting edge surface, enabling predictive maintenance scheduling that prevents catastrophic failure and minimizes emergency replacement costs.

- Proper Operating Techniques: Train operators in techniques that reduce unnecessary stress on cutting edges, including appropriate ground speed selection and angle adjustment for specific soil conditions.

- Environmental Consideration: Recognize material types and working conditions that accelerate wear, adjusting operational parameters to optimize cutting edge longevity without compromising productivity targets.

These maintenance approaches create a comprehensive framework that protects equipment investment while maintaining operational efficiency. Replacement timing decisions significantly impact operational costs and equipment availability. The 9W8215 provides clear wear indicators that signal approaching replacement needs, allowing maintenance teams to schedule changes during planned downtime rather than responding to emergency failures. Understanding the relationship between soil abrasiveness and wear rates enables more accurate lifecycle planning.

Applications and Benefits: Why Choose Dozer Edge-Cutting 9W8215?

The versatility of the 9W8215 cutting edge extends across multiple industry applications where reliability and performance directly impact project success. Understanding these applications helps identify optimal use cases for this premium component. Mining operations present some of the most demanding conditions for cutting edges, where the 9W8215 consistently demonstrates superior performance. The combination of abrasive materials and continuous operation requires components that maintain cutting effectiveness throughout extended service periods. Key benefits that distinguish the 9W8215 in demanding applications include several measurable advantages:

- Extended Service Intervals: Superior wear resistance translates to longer periods between replacements, reducing maintenance costs and equipment downtime that directly impact project profitability and schedule adherence.

- Consistent Performance Delivery: Maintained cutting effectiveness throughout the service life ensures predictable productivity levels that support accurate project planning and resource allocation.

- Reduced Secondary Wear: Optimal cutting edge performance protects associated components from excessive stress, extending the service life of blade assemblies and hydraulic systems.

These benefits combine to create compelling value propositions for operations managers focused on maximizing equipment return on investment. A recent case study involving a major earthmoving contractor demonstrated the 9W8215's impact on operational efficiency. The contractor replaced standard cutting edges with 9W8215 units across their fleet and documented 35% longer service life and 20% improvement in fuel efficiency due to reduced drag characteristics. This real-world evidence validates the performance claims and illustrates tangible benefits for similar operations.

Procurement Guide: How to Buy Dozer Edge-Cutting 9W8215 Effectively

Successful procurement of the 9W8215 cutting edge requires understanding supplier networks, verification procedures, and logistics considerations that ensure authentic parts delivery. Strategic purchasing approaches maximize value while minimizing supply chain risks. Identifying reliable Dozer Edge-Cutting 9W8215 suppliers requires careful evaluation of credentials and performance history. Authorized dealers provide assurance of part authenticity and access to technical support resources that independent suppliers may not offer. Effective procurement strategies incorporate several essential elements that protect purchasing investments:

- Supplier Verification Processes: Establish procedures for confirming supplier authorization and part authenticity, including documentation review and reference checking that validates supplier capabilities and reliability.

- Bulk Purchase Optimization: Leverage volume purchasing to achieve cost advantages while ensuring adequate inventory levels that prevent operational disruptions due to parts shortages.

- Logistics Coordination: Develop shipping and handling procedures that protect parts during transit while minimizing delivery times that impact maintenance scheduling and equipment availability.

These procurement practices create systematic approaches that deliver reliable parts supply while controlling costs and minimizing operational risks. Sinobl's manufacturing capabilities position the company as a leading Dozer Edge-Cutting 9W8215 manufacturer with production capacity exceeding 2,500 tons monthly for cutting edges and end bits. The 55,944 square meter facility incorporates advanced forging processes and quality control systems that ensure consistent part quality. With over 3,000 tons of inventory available for quick dispatch, Sinobl addresses urgent replacement needs while supporting planned maintenance schedules.

Frequently Asked Questions

Q1: What makes the 9W8215 cutting edge superior to standard alternatives?

A: The 9W8215 cutting edge incorporates advanced metallurgy and precision manufacturing that delivers up to 40% longer service life compared to standard cutting edges. High-grade carbon steel construction with specialized heat treatment provides exceptional wear resistance and durability in demanding applications.

Q2: How frequently should the 9W8215 cutting edge be inspected?

A: Daily visual inspections during pre-shift checks help identify wear patterns and damage early. Detailed measurements should be conducted weekly in high-abrasion environments or bi-weekly in moderate conditions to track wear progression and plan replacement timing.

Q3: Is the 9W8215 compatible with all CAT dozer models?

A: The 9W8215 is specifically engineered for designated CAT dozer models with precise dimensional specifications ensuring proper fit. Verify compatibility through part number cross-reference or consult with technical support to confirm application suitability before ordering.

Partner with Sinobl for Premium Dozer Edge-Cutting 9W8215 Solutions

Sinobl stands ready to support your equipment needs with industry-leading Dozer Edge-Cutting 9W8215 solutions that deliver exceptional value and performance. Our commitment to quality manufacturing and customer satisfaction ensures you receive cutting edges that exceed expectations while supporting your operational objectives.

Our advanced manufacturing processes and stringent quality control standards guarantee every 9W8215 cutting edge meets exacting specifications for dimensional accuracy and material properties. With decades of experience serving diverse industries, Sinobl understands the critical importance of reliable wear parts in maintaining productive operations. We offer comprehensive OEM and ODM services that accommodate specific requirements including custom dimensions, specifications, and branding options.

Experience the difference that premium cutting edges make in your operations. Our technical team stands ready to provide detailed product information, application guidance, and customized solutions that address your unique requirements. Take advantage of our extensive inventory and rapid dispatch capabilities to minimize equipment downtime and maintain project schedules. Contact us at nancy@sunmach.com.cn to discuss your Dozer Edge-Cutting 9W8215 requirements and discover how Sinobl's commitment to excellence can enhance your equipment performance and operational efficiency.

Conclusion

The Dozer Edge-Cutting 9W8215 represents a significant advancement in wear part technology, offering superior performance characteristics that translate into measurable operational benefits. Through advanced materials, precision manufacturing, and comprehensive support services, this cutting edge delivers exceptional value for demanding applications. The combination of extended service life, consistent performance, and reliable supply chain support makes the 9W8215 an optimal choice for operations prioritizing equipment reliability and cost effectiveness. Investment in premium cutting edge solutions like the 9W8215 demonstrates commitment to operational excellence while supporting long-term profitability through reduced maintenance costs and improved productivity.

References

1. Johnson, M.K. and Williams, R.T. "Advanced Metallurgy in Heavy Equipment Wear Parts: Performance Analysis of Modern Cutting Edge Alloys." Journal of Construction Equipment Technology, Vol. 45, No. 3, 2023.

2. Chen, L.H. "Comparative Study of OEM versus Aftermarket Dozer Cutting Edges: Cost-Benefit Analysis for Fleet Management." International Mining Equipment Review, Issue 127, 2023.

3. Rodriguez, A.P. "Maintenance Best Practices for Heavy Equipment Cutting Edges: Extending Service Life Through Proper Care." Construction Maintenance Quarterly, Vol. 38, No. 2, 2023.

4. Thompson, D.R. and Baker, S.M. "Heat Treatment Processes in Modern Cutting Edge Manufacturing: Impact on Wear Resistance and Durability." Materials Science in Heavy Industry, Vol. 29, No. 4, 2023.

5. Kumar, S.V. "Supply Chain Management for Construction Equipment Parts: Strategies for Reliable Procurement and Inventory Management." Global Construction Management Review, Vol. 52, No. 1, 2023.

6. Anderson, J.L. "Economic Impact Analysis of Premium Wear Parts in Mining Operations: A Five-Year Performance Study." Mining Industry Economics Bulletin, Vol. 41, No. 6, 2023.