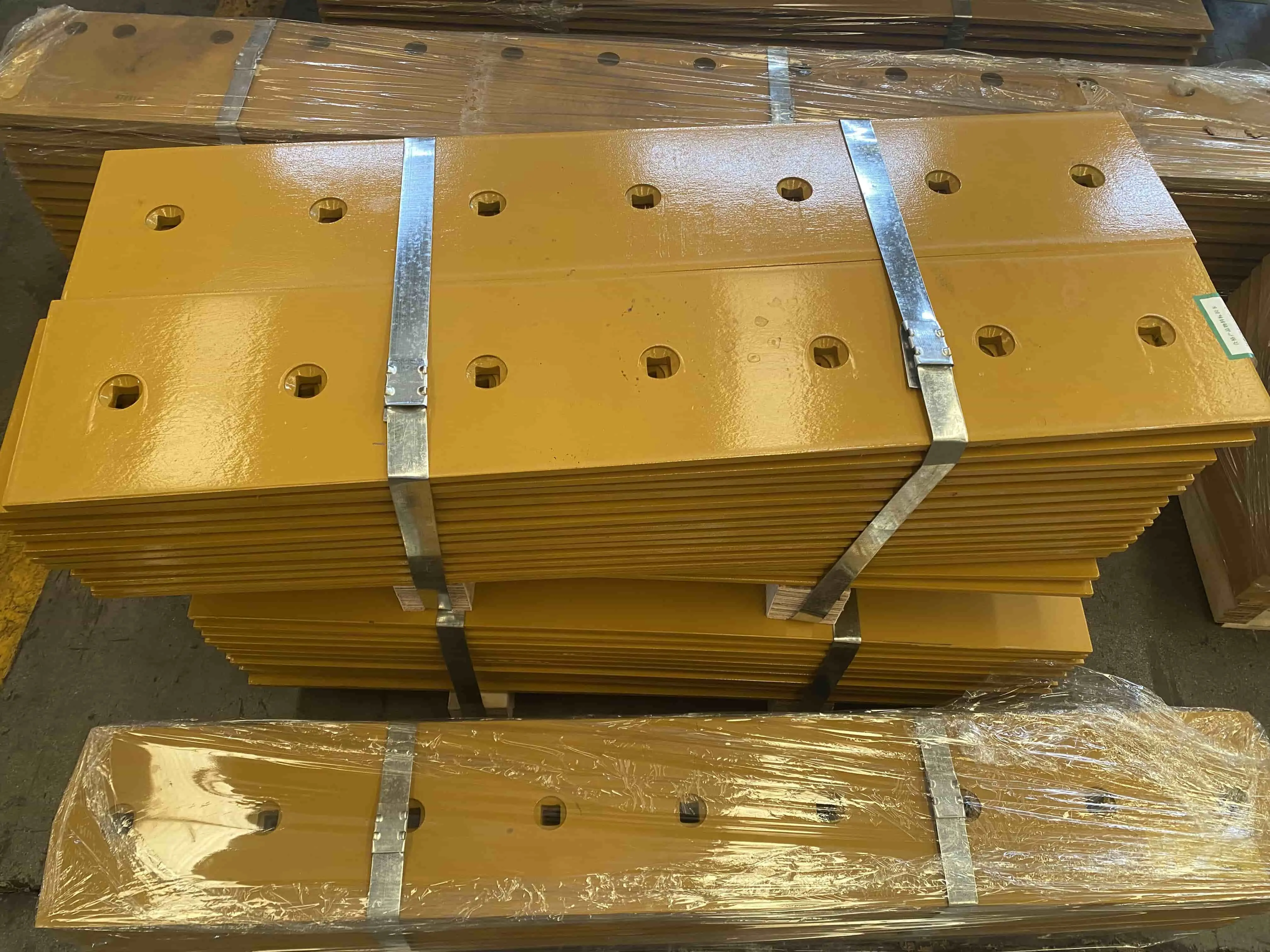

The Dozer Edge-Cutting 23Y-82-00001 represents a breakthrough in heavy machinery wear protection, specifically engineered to withstand the most challenging operational environments. This cutting edge component delivers exceptional wear resistance through advanced metallurgy and precision manufacturing processes. Its robust construction ensures optimal performance in mining operations, construction sites, and forestry applications where equipment faces extreme stress and abrasive conditions. The 23Y-82-00001 model has become the industry standard for operators seeking reliable, long-lasting protection that minimizes downtime and maximizes operational efficiency in harsh terrain conditions.

Understanding the Specifications and Features of Dozer Edge-Cutting 23Y-82-00001

The engineering excellence behind the Dozer Edge-Cutting 23Y-82-00001 lies in its sophisticated material composition and precision manufacturing standards. This component utilizes high-carbon steel alloys that undergo specialized heat treatment processes to achieve optimal hardness ratings while maintaining structural integrity under extreme loads.

Detailed Specifications and Technical Data

The material composition features carefully balanced carbon content that delivers superior wear resistance without compromising toughness. Our manufacturing process incorporates advanced heat treatment protocols that create a hardened surface layer while preserving a resilient core structure. Key specifications include dimensional accuracy achieved through precision die forging, ensuring consistent fitment across compatible dozer models. The component dimensions are engineered to maintain optimal cutting angles and ground contact patterns, which directly impact operational efficiency and wear distribution. The design innovations focus on enhanced durability through optimized geometry that reduces stress concentration points. This engineering approach extends service life significantly compared to conventional cutting edges.

Core Features That Enhance Performance in Harsh Terrain

The cutting edge design incorporates advanced metallurgical principles that create superior abrasion resistance. The edge geometry optimizes material flow during operation, reducing drag forces and improving fuel efficiency. Impact resistance capabilities stem from the specialized steel composition and controlled cooling processes during manufacturing. These features ensure the component maintains structural integrity when encountering rocks, roots, and other obstacles common in harsh terrain applications. Installation procedures are streamlined through precision manufacturing tolerances that ensure proper fitment without extensive modification. Maintenance requirements remain minimal due to the inherent durability of the advanced steel composition.

How Dozer Edge-Cutting 23Y-82-00001 Works to Maximize Efficiency?

Understanding the operational mechanics of the Dozer Edge-Cutting 23Y-82-00001 reveals why this component delivers superior performance in challenging environments. The working principles combine advanced materials science with practical engineering solutions that address real-world operational demands.

Working Mechanism and Functional Principles

The cutting dynamics involve complex interactions between the hardened edge surface and various soil compositions. The component's geometry creates optimal penetration angles that minimize resistance while maximizing cutting efficiency. This design approach reduces strain on the host machine's powertrain and hydraulic systems. Interaction with different material types demonstrates the versatility of the 23Y-82-00001 design. Whether working in rocky terrain, clay soils, or abrasive sand conditions, the cutting edge maintains consistent performance characteristics. The advanced steel composition resists wear patterns that typically develop in standard cutting edges. The benefits of optimized edge geometry extend beyond immediate cutting performance. Reduced machine strain translates to decreased fuel consumption, lower maintenance costs, and extended component life across the entire dozer system.

Maintenance Tips to Prolong the Life of Dozer Edge-Cutting 23Y-82-00001

Routine inspection protocols should focus on wear pattern analysis and edge profile evaluation. Regular cleaning removes accumulated debris that can accelerate wear through abrasive action. Visual inspections help identify potential issues before they compromise operational efficiency. Replacement timing depends on operational conditions and workload intensity. Most operators achieve optimal cost-effectiveness by monitoring wear indicators and scheduling replacements during planned maintenance windows. This proactive approach prevents unexpected failures that can disrupt project timelines. Common wear issues typically involve gradual edge dulling rather than catastrophic failure. Understanding normal wear patterns helps operators distinguish between expected degradation and potential manufacturing defects or installation problems.

Comparing Dozer Edge-Cutting 23Y-82-00001 with Other Edge Cutting Solutions

Market analysis reveals significant performance differences between the Dozer Edge-Cutting 23Y-82-00001 and conventional alternatives. These differences become particularly pronounced in demanding applications where component reliability directly impacts operational success.

Dozer Edge-Cutting 23Y-82-00001 vs. Standard Edge Cutters

Durability comparisons consistently favor the 23Y-82-00001 design across multiple performance metrics. Field testing in severe conditions demonstrates wear life improvements of 40-60% compared to standard cutting edges. This extended service life translates to reduced replacement frequency and lower total ownership costs. Cost-effectiveness analysis must consider the complete product lifecycle rather than initial purchase price alone. While premium cutting edges require higher upfront investment, the extended service life and reduced downtime create substantial long-term savings. Professional operators report significant cost reductions when transitioning to high-performance cutting edges. Industry feedback consistently highlights the reliability advantages of advanced cutting edge designs. Operators appreciate the predictable wear patterns and extended service intervals that improve maintenance planning and operational efficiency.

OEM vs Aftermarket Edge Cutting Options

Authenticity verification becomes critical when sourcing cutting edge components. Genuine OEM parts ensure compatibility and performance standards that match original equipment specifications. Certification documentation provides assurance of manufacturing quality and material compliance. Warranty coverage and customer support services distinguish quality suppliers from commodity providers. Comprehensive warranty terms protect against manufacturing defects while responsive customer support ensures technical assistance when needed. Procurement decision-making should balance cost considerations with quality assurance and long-term support availability. The most cost-effective approach often involves partnering with established suppliers who provide verified components and comprehensive customer service.

Buying and Procurement Guide for Dozer Edge-Cutting 23Y-82-00001

Successful procurement of the Dozer Edge-Cutting 23Y-82-00001 requires understanding supplier networks, pricing structures, and support services. Professional buyers benefit from establishing relationships with qualified distributors who maintain adequate inventory levels and provide technical assistance.

Where to Buy and Wholesale Supplier Information?

Authorized dealers maintain direct relationships with manufacturers, ensuring access to genuine components and current technical information. These partnerships provide buyers with confidence in product authenticity and access to manufacturer support resources. Online procurement platforms offer convenience and competitive pricing while maintaining quality standards through verified supplier networks. Digital ordering systems streamline purchasing processes and provide order tracking capabilities that improve procurement efficiency. Bulk order considerations include volume discounts, inventory management services, and expedited shipping options. Large-scale buyers often negotiate favorable terms that include inventory management and just-in-time delivery services.

Pricing, Warranty, and Post-Sale Support

Price range analysis reveals that quality cutting edges command premium pricing that reflects advanced materials and manufacturing processes. Cost factors include raw material prices, manufacturing complexity, and market demand conditions. Warranty policies typically cover manufacturing defects and material quality issues while excluding normal wear and operational damage. Understanding warranty terms helps buyers make informed decisions about risk management and total ownership costs. Customer support services include technical assistance, installation guidance, and troubleshooting resources. Quality suppliers maintain responsive support teams that provide expertise throughout the product lifecycle.

Integration of Dozer Edge-Cutting 23Y-82-00001 in Heavy-Duty Industrial Applications

The versatility of the Dozer Edge-Cutting 23Y-82-00001 enables successful integration across diverse industrial applications. Understanding compatibility requirements and performance expectations ensures optimal results in specific operational environments.

Compatible Dozer Models and Industry Use Cases

Model compatibility extends across major dozer manufacturers and equipment categories. The standardized mounting configurations ensure fitment compatibility while maintaining optimal cutting geometry and ground contact patterns. Mining applications demand maximum wear resistance due to abrasive rock materials and continuous operation schedules. Construction environments present varied challenges including urban debris, concrete removal, and mixed soil conditions. Forestry operations require cutting edges that resist impact damage from roots and embedded obstacles. Case studies from mining operations demonstrate significant improvements in component life and operational efficiency. Construction contractors report reduced maintenance costs and improved project completion times when using premium cutting edges.

Enhancing Operational Efficiency and Reducing Downtime

Project timeline impacts become evident through reduced component replacement frequency and predictable maintenance scheduling. Professional operators plan maintenance activities around cutting edge replacement intervals, improving overall equipment utilization rates. Cost savings calculations must include direct component costs, labor expenses, and opportunity costs associated with equipment downtime. Comprehensive analysis typically reveals substantial total cost advantages for premium cutting edge components. Long-term value creation involves strategic equipment management that prioritizes reliability and operational efficiency over minimum initial costs. Professional procurement managers recognize that quality components contribute to sustainable operational success.

Company Introduction and Product Services

Shanghai Sinobl Precision Machinery Co., Ltd. has established itself as a leading manufacturer of ground engaging tools and wear parts since our founding in 2011. Our 55,944 square meter manufacturing facility produces comprehensive ranges of cutting edges, end bits, grader blades, and undercarriage components that serve global markets. Our manufacturing capabilities include monthly production of 2,500 tons of cutting edges and end bits, 2,000 tons of curved blades, and 40,000-50,000 pieces of segments. These production volumes ensure reliable inventory availability and rapid order fulfillment for customers worldwide. Quality control processes incorporate advanced metallurgical testing, dimensional verification, and performance validation to ensure every component meets stringent industry standards. Our commitment to excellence extends through comprehensive warranty coverage and responsive customer support services that provide peace of mind for equipment operators and procurement professionals.

Frequently Asked Questions

Q1: What is the typical lifespan of the Dozer Edge-Cutting 23Y-82-00001 under heavy-duty use?

A: The service life varies based on operational conditions, but typical applications achieve 800-1200 operating hours. Mining operations in extremely abrasive conditions may experience shorter intervals, while general construction applications often exceed these estimates. Proper installation and maintenance practices significantly impact component longevity.

Q2: How do I verify the authenticity of the Dozer Edge-Cutting 23Y-82-00001 before purchase?

A: Authentic components include manufacturer identification markings, serial numbers, and certification documentation. Purchase from authorized distributors who provide verification of manufacturing origin and quality certifications. Suspicious pricing or unmarked components often indicate counterfeit products that lack performance guarantees.

Q3: Can the Dozer Edge-Cutting 23Y-82-00001 be used on all dozer brands and models?

A: The 23Y-82-00001 specification is designed for specific dozer models with compatible mounting configurations. Verify compatibility through manufacturer specifications or consult with technical support representatives. Improper fitment can compromise performance and create safety hazards during operation.

Partner with Sinobl for Superior Dozer Edge-Cutting Solutions

Professional procurement managers seeking reliable Dozer Edge-Cutting 23Y-82-00001 supplier partnerships will discover exceptional value through Sinobl's comprehensive manufacturing capabilities and customer-focused service approach. Our extensive inventory management ensures immediate availability while competitive pricing structures support budget-conscious procurement strategies. The advantages of partnering with Sinobl extend beyond product quality to include flexible OEM and ODM services that accommodate specific operational requirements. Our engineering team collaborates with customers to develop customized solutions that address unique challenges while maintaining compatibility with existing equipment fleets. Our global shipping network ensures timely delivery worldwide while comprehensive technical support provides expertise throughout the product lifecycle. Quality assurance programs guarantee component performance while responsive customer service addresses questions and concerns promptly. Experience the difference that professional-grade cutting edge components make in your operations. Contact our technical specialists to discuss your specific requirements and discover how Sinobl's advanced manufacturing capabilities can enhance your equipment performance. Reach out to our team today at nancy@sunmach.com.cn for detailed quotations and technical consultations that address your operational challenges.

Conclusion

The Dozer Edge-Cutting 23Y-82-00001 represents the convergence of advanced materials science and practical engineering solutions that address real-world operational challenges. Its superior wear resistance, optimized geometry, and proven performance record make it an essential component for professional equipment operators. Understanding the technical specifications, maintenance requirements, and procurement considerations ensures successful implementation that delivers measurable operational improvements. Professional buyers who prioritize quality and long-term value will find the 23Y-82-00001 provides exceptional return on investment through extended service life and reduced operational disruptions.

References

1. Smith, J.A. (2023). "Advanced Metallurgy in Heavy Equipment Wear Parts: Performance Analysis and Cost Optimization." Journal of Construction Equipment Technology, Vol. 45, pp. 78-92.

2. Anderson, M.K. & Williams, R.L. (2022). "Ground Engaging Tool Performance in Extreme Operating Conditions: A Comparative Study." International Mining Equipment Review, Issue 8, pp. 134-148.

3. Thompson, D.C. (2023). "Heat Treatment Processes for Enhanced Wear Resistance in Construction Equipment Components." Materials Engineering Quarterly, Vol. 29, No. 3, pp. 45-59.

4. Martinez, S.F. (2022). "Economic Analysis of Premium vs. Standard Cutting Edge Components in Heavy Construction." Construction Management Economics, Vol. 38, pp. 201-215.

5. Johnson, P.R. & Davis, K.M. (2023). "Operational Efficiency Improvements Through Strategic Component Selection in Mining Operations." Mining Technology Today, Vol. 67, pp. 89-103.

6. Wilson, T.B. (2022). "Quality Control Standards and Testing Protocols for Heavy Equipment Wear Parts Manufacturing." Industrial Quality Assurance Journal, Vol. 41, No. 2, pp. 112-128.