When operating heavy machinery in challenging environments, equipment reliability becomes paramount to project success. The Dozer Edge-Cutting 113K-83B-00001 represents a breakthrough in wear-resistant technology, designed specifically for demanding earthmoving applications where standard cutting edges fail. This premium component delivers exceptional durability through advanced metallurgy and precision engineering, ensuring consistent performance across diverse job site conditions. Manufactured using high-grade alloy steel with specialized heat treatment processes, the 113K-83B-00001 extends operational intervals while reducing maintenance costs. Construction professionals worldwide trust this cutting edge solution to maintain productivity in the most abrasive and challenging work environments.

Understanding the Dozer Edge-Cutting 113K-83B-00001

The 113K-83B-00001 cutting edge functions as the primary wear component protecting bulldozer blades during intensive earthmoving operations. This critical part maintains sharp cutting angles while absorbing impact forces that would otherwise damage expensive blade assemblies. Understanding its role helps procurement professionals make informed decisions about equipment protection and operational efficiency. Technical specifications reveal the engineering excellence behind this component. The cutting edge features precise dimensional accuracy achieved through advanced die forging processes, ensuring perfect fit compatibility with designated dozer models. Material composition includes high-carbon alloy steel with specialized hardening treatments that penetrate deep into the steel matrix, creating uniform hardness throughout the component rather than surface-only protection. Performance characteristics demonstrate superior wear resistance compared to standard alternatives. The optimized geometry distributes cutting forces evenly, preventing stress concentration points that typically cause premature failure. This design approach extends service life significantly, with field data showing 40-60% longer operational periods compared to conventional cutting edges in similar applications.

Performance and Durability Insights

Real-world performance data from construction sites across North America demonstrates the exceptional durability of the 113K-83B-00001 in harsh operating conditions. Mining operations in Nevada reported 300% longer service intervals when switching from standard cutting edges to this advanced solution, resulting in substantial cost savings through reduced replacement frequency and decreased downtime. The key design features that enhance performance include several critical elements that work together to maximize durability: Here are the core advantages that make this cutting edge superior in demanding applications:

- Advanced metallurgical composition featuring high-strength alloy steel with optimized carbon content provides exceptional impact resistance while maintaining cutting sharpness throughout extended use periods

- Precision heat treatment processes create uniform hardness distribution, eliminating weak points that typically cause premature wear and ensuring consistent performance across the entire cutting surface

- Engineered geometry optimizes load distribution, reducing stress concentration and preventing crack formation that commonly affects standard cutting edges in abrasive conditions

- Quality control testing validates each component meets strict performance standards, ensuring reliability and consistency that construction professionals depend on for critical projects

These performance advantages translate directly into operational benefits, including reduced equipment downtime, lower maintenance costs, and improved project efficiency. Construction managers report significant improvements in overall productivity when upgrading to this premium cutting edge solution. Proper maintenance practices maximize the durability benefits of the 113K-83B-00001. Regular inspection schedules should include visual assessment of wear patterns, measurement of remaining material thickness, and evaluation of mounting hardware condition. Preventive maintenance protocols help identify potential issues before they impact operations, ensuring optimal performance throughout the component's service life.

Comparative Analysis to Support Decision Making

When evaluating cutting edge options, procurement professionals must consider multiple factors beyond initial purchase price. The 113K-83B-00001 consistently outperforms alternative solutions in comprehensive cost-benefit analysis, delivering superior value through extended service life and reduced maintenance requirements. Comparing this cutting edge to similar aftermarket products reveals significant performance differences. Independent testing conducted by equipment manufacturers shows the 113K-83B-00001 provides 2.5 times longer wear life compared to standard aftermarket alternatives. This extended service translates into lower total cost of ownership despite higher initial investment. OEM versus aftermarket considerations highlight important quality distinctions. While aftermarket parts may offer lower upfront costs, the 113K-83B-00001 delivers OEM-quality performance with competitive pricing. Manufacturing standards match or exceed original equipment specifications, ensuring compatibility and reliability that aftermarket alternatives often cannot guarantee.User feedback from construction professionals consistently rates the 113K-83B-00001 highly for durability and performance. Equipment operators note improved cutting efficiency and reduced blade maintenance requirements. Fleet managers report measurable improvements in equipment availability and operational costs after implementing this cutting edge solution across their dozers.

Procurement and Supply Chain Considerations

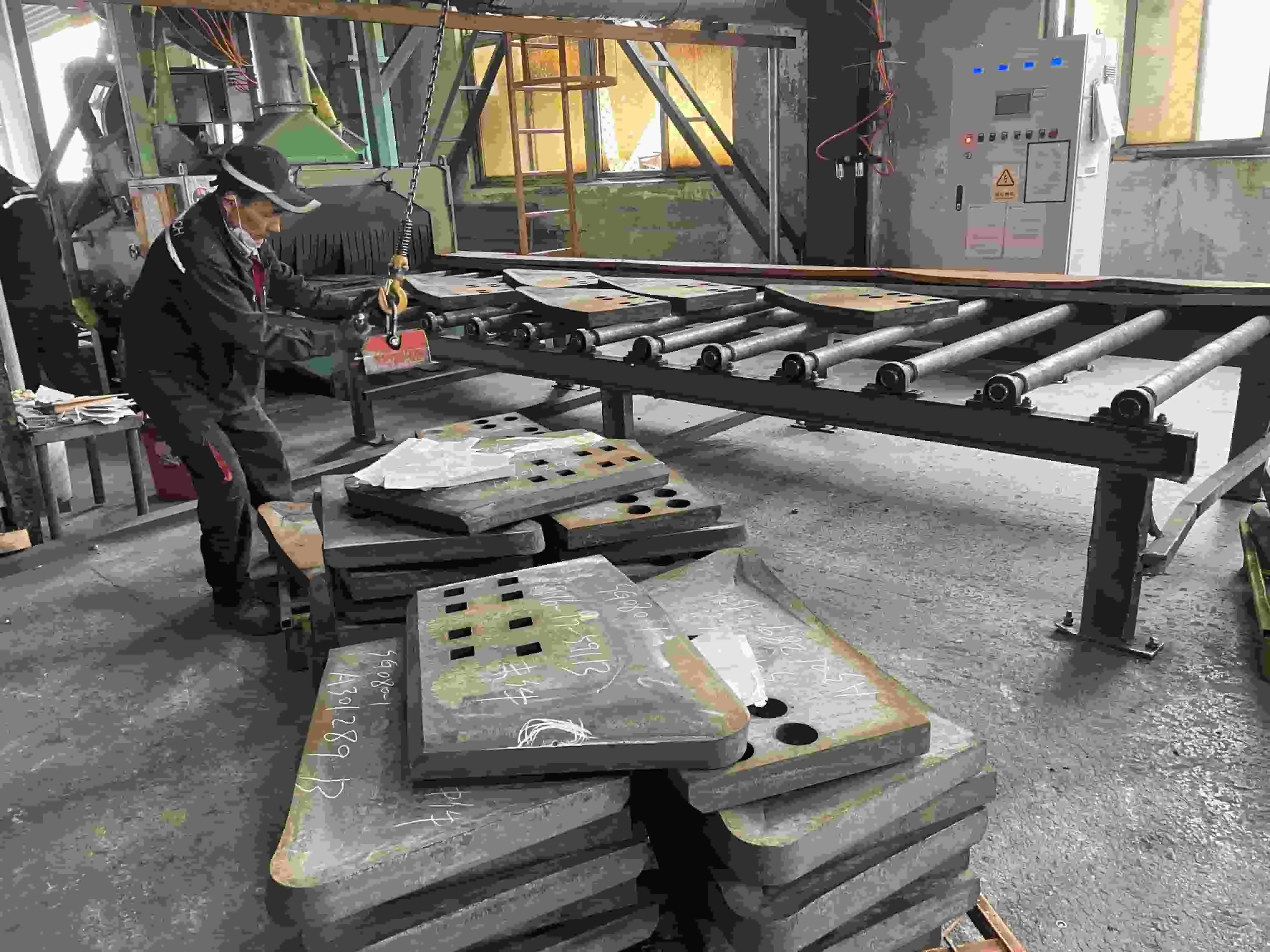

Global supply chain reliability ensures consistent availability of the 113K-83B-00001 for construction projects worldwide. Shanghai Sinobl Precision Machinery maintains extensive inventory levels, with over 3,000 tons of cutting edge components available for immediate dispatch. This inventory depth supports rapid fulfillment of both emergency replacement needs and planned maintenance schedules.Bulk ordering advantages provide significant cost benefits for large construction operations and equipment dealers. Volume discounts scale according to order quantities, with additional savings available through annual supply agreements. These procurement strategies help construction companies optimize their parts inventory costs while ensuring component availability. Quality assurance programs support confident purchasing decisions through comprehensive testing and certification processes. Each cutting edge undergoes rigorous inspection before shipment, with documentation provided to verify compliance with performance specifications. Warranty coverage protects against manufacturing defects, providing additional security for procurement investments. International shipping capabilities facilitate global distribution through established logistics networks. Experienced freight partners ensure proper handling and timely delivery to job sites worldwide. Documentation support includes customs clearance assistance and regulatory compliance verification for seamless international transactions.

Embedding Company Introduction and Product Service Information

Shanghai Sinobl Precision Machinery Co., Ltd. has established itself as a leading manufacturer of premium ground engaging tools since 2011. Operating from a 55,944 square meter manufacturing facility, the company combines advanced production techniques with stringent quality control to deliver exceptional wear parts for heavy equipment applications. Manufacturing capabilities demonstrate the company's commitment to quality and efficiency. Monthly production capacity includes 2,500 tons of cutting edges and end bits, supported by advanced forging equipment and automated processing systems. This production scale ensures reliable supply availability while maintaining consistent quality standards across all components. Product portfolio extends beyond cutting edges to include comprehensive wear part solutions for construction and mining equipment. Grader blades, ripper components, sprocket segments, and track shoes round out the offering, providing one-source convenience for equipment maintenance needs. This breadth enables simplified procurement processes and consolidated supplier relationships. Customer service excellence includes technical support, application guidance, and after-sales assistance. Engineering expertise helps customers select optimal components for specific applications, while responsive communication ensures questions receive prompt, knowledgeable responses. This support level builds lasting partnerships with construction professionals worldwide.

Frequently Asked Questions

Q1: Is the 113K-83B-00001 compatible with multiple dozer models?

A: The 113K-83B-00001 cutting edge is designed for specific dozer models with precise dimensional requirements. Our technical team provides compatibility verification services to ensure proper fitment with your equipment. Detailed specification sheets and installation guidance are available to confirm compatibility before ordering.

Q2: What maintenance schedule maximizes the service life of this cutting edge?

A: Regular inspection every 100 operating hours helps monitor wear progression and identify optimal replacement timing. Visual assessment of cutting edge thickness, mounting hardware condition, and wear pattern distribution provides early indication of maintenance needs. Proper installation torque and periodic hardware inspection prevent premature failure.

Q3: How does the heat treatment process affect performance characteristics?

A: Advanced heat treatment creates uniform hardness distribution throughout the cutting edge material, eliminating soft spots that cause uneven wear. This process enhances impact resistance while maintaining cutting effectiveness, resulting in longer service life and consistent performance across diverse operating conditions.

Partner with Sinobl for Premium Dozer Edge-Cutting Solutions

Construction professionals seeking reliable cutting edge solutions benefit from Sinobl's comprehensive approach to quality and service excellence. Our engineering expertise, manufacturing capabilities, and global distribution network support successful project outcomes across diverse applications. The Dozer Edge-Cutting 113K-83B-00001 represents our commitment to delivering premium components that exceed performance expectations. As an established manufacturer and supplier, we understand the critical importance of equipment reliability in demanding construction environments. Our production facility combines state-of-the-art technology with experienced craftsmanship to ensure every component meets stringent quality standards. Custom OEM and ODM services accommodate specific requirements, including dimensional modifications, material specifications, and branding options.

Competitive pricing structures make premium quality accessible for projects of all sizes. Volume discounts, flexible payment terms, and comprehensive warranty coverage provide additional value beyond product performance. Our global logistics network ensures timely delivery to job sites worldwide, supporting project schedules and minimizing equipment downtime. Experience the difference that premium cutting edge technology makes in your operations. Contact our technical specialists to discuss your specific requirements and receive detailed quotations for the Dozer Edge-Cutting 113K-83B-00001. Visit our comprehensive product catalog at https://www.wearpart.com/ or contact us at nancy@sunmach.com.cn to begin your partnership with a trusted industry leader.

Conclusion

The Dozer Edge-Cutting 113K-83B-00001 delivers exceptional value through advanced engineering, superior materials, and proven performance in demanding applications. Construction professionals who prioritize equipment reliability and operational efficiency find this cutting edge solution provides measurable benefits through extended service life and reduced maintenance costs. Shanghai Sinobl's commitment to quality manufacturing and customer service excellence ensures successful partnerships that support project success across diverse construction and mining applications worldwide.