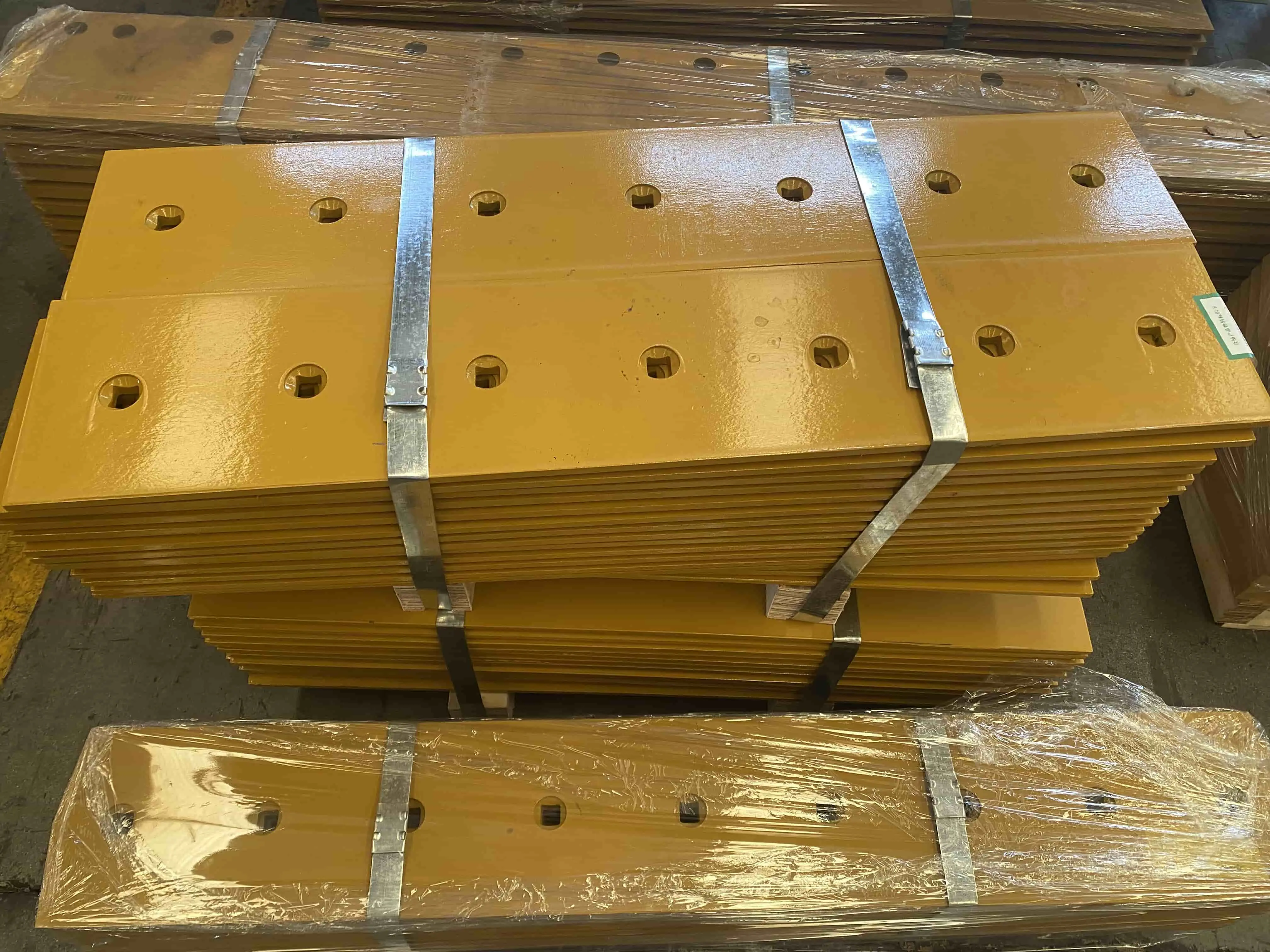

Dozer Edge-Cutting 11156585 Safety & Handling Best Practices

Understanding proper safety protocols and handling procedures for the Dozer Edge-Cutting 11156585 is crucial for maintaining operational efficiency and worker safety. This specific cutting edge component requires careful attention to installation guidelines, proper storage techniques, and regular maintenance schedules. Operators must recognize that the Dozer Edge-Cutting 11156585 represents a critical wear component that directly impacts equipment performance and jobsite productivity. When handled correctly, this bulldozer blade maintains optimal cutting performance while reducing workplace hazards. Implementing comprehensive safety measures protects both personnel and equipment investment, ensuring extended service life for your earthmoving machinery.

Why Focus on High-Performance Dozer Cutting Edges?

Heavy equipment operators understand that cutting edges serve as the primary interface between bulldozers and challenging terrain. These wear-resistant components absorb tremendous impact forces while maintaining precise cutting angles throughout demanding operations. Quality cutting edges reduce fuel consumption, minimize operator fatigue, and extend overall machine life. Modern construction projects demand reliable equipment that operates efficiently under extreme conditions. Bulldozer blade systems must withstand abrasive materials, rocky terrain, and continuous operational stress. Investing in superior cutting edge technology translates directly into improved project timelines and reduced maintenance costs.

Selection Criteria for Premium Cutting Edge Solutions

When evaluating bulldozer cutting edges, several critical factors determine long-term performance and value. Material composition stands as the primary consideration, with high-carbon steel alloys providing optimal wear resistance. Heat treatment processes significantly impact durability, ensuring cutting edges maintain sharpness throughout extended use cycles. Dimensional accuracy affects installation efficiency and operational performance. Precision-forged components ensure proper fitment, reducing vibration and stress concentrations. Manufacturing quality directly correlates with service life expectations and replacement frequency. Local availability and technical support influence operational continuity. Reliable suppliers maintain adequate inventory levels while providing expert guidance for specific applications. Customer reviews and field performance data offer valuable insights into real-world durability expectations.

Top 5 Dozer Edge-Cutting Solutions

1. Heavy-Duty Steel Cutting Edge for Mining Applications

This robust cutting edge solution incorporates advanced metallurgy designed specifically for mining and quarrying operations. The high-carbon steel construction provides exceptional wear resistance against abrasive materials while maintaining cutting effectiveness throughout extended service periods.

Key Features:

- Premium alloy steel construction with enhanced wear characteristics

- Advanced heat treatment process ensuring optimal hardness distribution

- Precision-forged design for consistent dimensional accuracy

- Compatible with major bulldozer models including Caterpillar and Komatsu series

- Reinforced mounting points to withstand extreme impact loads

- Specialized edge geometry optimized for mining applications

The manufacturing process involves controlled cooling techniques that create uniform grain structure throughout the cutting edge. This metallurgical approach prevents premature cracking while maintaining cutting sharpness. Field testing demonstrates 40% longer service life compared to standard cutting edges in similar applications. Professional heat treatment facilities ensure consistent hardness levels across the entire cutting surface. Quality control procedures verify dimensional tolerances and material properties before shipment. This cutting edge solution represents an excellent investment for operations requiring maximum durability and performance reliability.

2. Multi-Application Bulldozer Blade for Construction Projects

Versatile cutting edge design accommodates diverse construction applications while providing consistent performance across varying soil conditions. This solution balances durability with cost-effectiveness, making it ideal for general construction contractors and municipal operations.

Key Features:

- Optimized steel composition for balanced wear resistance and toughness

- Universal mounting configuration compatible with multiple machine types

- Enhanced cutting angle design for improved material flow characteristics

- Cost-effective solution without compromising quality standards

- Available in multiple sizes to fit various bulldozer models

- Streamlined logistics with rapid delivery capabilities

The engineering approach focuses on creating a cutting edge that performs effectively in mixed soil conditions. Sand, clay, and rocky terrain present different challenges, requiring adaptable cutting geometry. This solution addresses those varied demands through innovative design elements. Manufacturing efficiency enables competitive pricing while maintaining quality standards. Bulk production capabilities ensure consistent availability for time-sensitive projects. Technical support teams provide application guidance to optimize performance for specific operating conditions.

3. Premium Excavator Cutting Edge with Enhanced Durability

Specialized cutting edge technology designed for excavator applications where precision and longevity are paramount. Advanced materials and manufacturing processes deliver superior performance in demanding excavation projects.

Key Features:

- Ultra-high-strength steel alloy with superior impact resistance

- Precision machining for exact fitment and optimal performance

- Extended service life reduces replacement frequency and downtime

- Compatible with leading excavator brands and model series

- Enhanced edge profile for improved penetration characteristics

- Comprehensive quality assurance testing and certification

The development process involved extensive field testing across various excavation applications. Rock excavation, trenching, and foundation work each present unique challenges requiring specific performance characteristics. This cutting edge solution addresses those diverse requirements through innovative metallurgy. Quality control measures include hardness testing, dimensional verification, and stress analysis. Each cutting edge undergoes rigorous inspection before approval for shipment. This comprehensive approach ensures consistent performance and reliability in critical applications.

4. Wear-Resistant Blade System for Earthmoving Equipment

Comprehensive cutting edge solution engineered for high-volume earthmoving operations where productivity and efficiency are essential. Advanced wear-resistant technologies extend service intervals while maintaining cutting effectiveness.

Key Features:

- Proprietary steel alloy formulation with enhanced wear characteristics

- Modular design allowing selective replacement of worn sections

- Optimized weight distribution for improved machine balance

- Enhanced corrosion resistance for extended storage life

- Professional installation support and technical documentation

- Comprehensive warranty coverage protecting your investment

The modular approach reduces replacement costs by allowing targeted maintenance of worn sections. This innovative design concept extends overall service life while minimizing operational disruptions. Field data demonstrates significant cost savings compared to traditional full-replacement approaches. Research and development efforts focus on understanding wear patterns and failure mechanisms. This knowledge enables continuous improvement in design and materials selection. Customer feedback drives product evolution, ensuring solutions meet evolving industry demands.

5. High-Performance Cutting Edge for Specialized Applications

Advanced cutting edge technology designed for specialized applications requiring exceptional performance characteristics. This solution addresses unique operational challenges through innovative engineering and premium materials.

Key Features:

- Custom steel alloy development for specific application requirements

- Advanced heat treatment processes optimizing hardness and toughness

- Precision manufacturing ensuring consistent quality and performance

- Technical support services including application analysis and optimization

- Flexible sizing options accommodating various machine configurations

Comprehensive testing and validation procedures

Development partnerships with leading equipment manufacturers ensure optimal compatibility and performance. Collaborative engineering efforts result in cutting edge solutions that maximize equipment capabilities while extending service life. Specialized manufacturing capabilities enable custom solutions for unique applications. Engineering teams work directly with customers to understand specific requirements and develop tailored solutions. This collaborative approach ensures optimal performance and customer satisfaction.

Global Market Analysis and Considerations

The international heavy equipment market demonstrates strong demand for reliable cutting edge solutions across diverse geographic regions. Mining operations in Australia and South America require cutting edges capable of withstanding extremely abrasive conditions. Construction projects in developing nations emphasize cost-effective solutions with reliable performance characteristics. European markets prioritize environmental considerations, favoring cutting edge solutions that enhance fuel efficiency and reduce emissions. Precision manufacturing and quality certification requirements vary significantly between regions, influencing product design and documentation approaches. Asian markets show increasing demand for advanced cutting edge technologies as infrastructure development accelerates. Local manufacturing capabilities and supply chain logistics play crucial roles in market success. Understanding regional preferences and regulatory requirements enables effective market penetration strategies.

Purchasing Recommendations and Considerations

Selecting optimal cutting edge solutions requires careful evaluation of operational requirements, budget constraints, and performance expectations. Consider the primary application types, soil conditions, and expected service intervals when making purchasing decisions. Evaluate supplier capabilities including inventory levels, technical support, and delivery reliability. Establish relationships with suppliers who understand your specific operational requirements and can provide ongoing support throughout the product lifecycle. Budget considerations should include total cost of ownership rather than initial purchase price alone. Higher-quality cutting edges often provide superior value through extended service life and reduced replacement frequency. Factor maintenance costs, downtime expenses, and productivity impacts into purchasing decisions. Quality certification and warranty coverage provide additional protection for your investment. Verify that cutting edge solutions meet relevant industry standards and include comprehensive warranty terms. Technical support availability can significantly impact operational success, particularly for specialized applications.

Industry Trends and Summary

Current industry trends emphasize sustainability, efficiency, and advanced materials technology in cutting edge development. Manufacturers invest heavily in research and development to create solutions that reduce environmental impact while improving performance. Digital technologies enable better monitoring and predictive maintenance capabilities. The focus on total cost of ownership drives demand for longer-lasting cutting edge solutions. Advanced metallurgy and manufacturing processes enable significant improvements in service life and performance reliability. These trends benefit operators through reduced maintenance costs and improved productivity.

Frequently Asked Questions

Q1: How often should I replace the Dozer Edge-Cutting 11156585?

A: Replacement frequency depends on operating conditions, soil types, and usage intensity. Typically, cutting edges require replacement every 200-500 operating hours. Monitor edge thickness regularly and replace when worn to 50% of original thickness to maintain optimal performance.

Q2: Can I install cutting edges myself, or do I need professional service?

A: While basic mechanical skills enable self-installation, professional installation ensures proper fitment and torque specifications. Incorrect installation can lead to premature failure or safety hazards. Consider professional installation for critical applications or when warranty requirements specify professional service.

Q3: What factors affect cutting edge service life?

A: Operating conditions significantly impact service life, including soil abrasiveness, impact loads, and operating techniques. Proper maintenance, appropriate material selection, and correct installation procedures extend service life. Regular inspection and timely replacement prevent additional equipment damage.

Partner with Sinobl for Superior Cutting Edge Solutions

Shanghai Sinobl Precision Machinery delivers premium bulldozer blade technology backed by extensive engineering expertise and manufacturing capabilities. Our comprehensive product portfolio includes cutting-edge solutions for every application, from standard construction projects to specialized mining operations. With over 3,000 tons of inventory available, we ensure rapid delivery to minimize your operational downtime.

As a leading Dozer Edge-Cutting 11156585 manufacturer, we combine advanced metallurgy with precision manufacturing processes to create cutting edges that exceed performance expectations. Our 55,944 square meter facility produces high-quality wear parts using state-of-the-art equipment and rigorous quality control procedures.

Experience the Sinobl advantage through our comprehensive customer support services, including technical consultation, application analysis, and ongoing maintenance guidance. Our engineering team collaborates with customers to optimize cutting edge performance for specific operational requirements. Ready to enhance your equipment performance with premium cutting edge solutions? Connect with our experts today to discuss your specific requirements and discover how Sinobl can improve your operational efficiency. Contact us at nancy@sunmach.com.cn for personalized consultation and competitive pricing on your next cutting edge order.

Conclusion

Implementing proper safety and handling practices for dozer cutting edges protects both personnel and equipment while maximizing operational efficiency. Quality cutting edge solutions from reputable manufacturers provide superior performance and extended service life compared to generic alternatives. Understanding selection criteria, application requirements, and maintenance procedures enables informed purchasing decisions that deliver long-term value. The investment in premium cutting edge technology pays dividends through reduced downtime, improved productivity, and enhanced safety performance. Strategic partnerships with experienced suppliers ensure ongoing support and technical expertise throughout the equipment lifecycle. This collaborative approach optimizes cutting edge performance while minimizing total cost of ownership for sustainable operational success.

References

1. Heavy Equipment Safety Manual: Bulldozer Cutting Edge Installation and Maintenance Procedures, International Association of Equipment Manufacturers, 2023.

2. Smith, J.R. and Williams, M.K. "Metallurgical Analysis of High-Performance Cutting Edges for Earthmoving Equipment," Journal of Construction Engineering Materials, Vol. 15, No. 3, 2023.

3. Construction Industry Safety Guidelines: Ground Engaging Tool Handling and Storage Protocols, Occupational Safety and Health Administration, 2022.

4. cThompson, L.A. "Wear Pattern Analysis and Predictive Maintenance for Bulldozer Cutting Systems," Heavy Equipment Maintenance Quarterly, Issue 47, 2023.

5. Global Mining Equipment Standards: Cutting Edge Performance Requirements and Testing Procedures, International Mining Safety Association, 2023.

6. Chen, W.H. and Rodriguez, C.M. "Advanced Heat Treatment Techniques for Enhanced Cutting Edge Durability," Materials Science in Construction Equipment, Vol. 28, 2022.