The Dozer Edge-Cutting 11156585 represents a breakthrough in bulldozer cutting edge technology, delivering exceptional wear resistance and minimizing operational downtime through advanced metallurgy and precision engineering. This premium cutting edge solution extends equipment life cycles while reducing maintenance costs and unexpected breakdowns. Built with superior-grade steel and professional heat treatment processes, the 11156585 cutting edge provides contractors and fleet managers with reliable performance that translates into measurable productivity gains and enhanced return on investment for heavy-duty earthmoving operations.

Understanding Dozer Edge-Cutting 11156585: Advanced Engineering Specifications

The engineering excellence behind the Dozer Edge-Cutting 11156585 stems from decades of metallurgical research and field testing. This cutting edge features precision-forged construction using high-carbon steel alloys specifically formulated for extreme wear resistance. The manufacturing process incorporates controlled heat treatment cycles that achieve optimal hardness levels while maintaining toughness characteristics essential for impact resistance. Dimensional accuracy remains critical for proper fit and function across various dozer models. The 11156585 cutting edge maintains strict tolerance specifications that ensure seamless integration with existing blade assemblies. Weight distribution has been optimized to provide balanced cutting performance while minimizing stress concentrations that could lead to premature failure. The advanced surface hardening process creates a wear-resistant outer layer while preserving a tough inner core. This dual-hardness design prevents edge chipping and cracking common in standard cutting edges. Material composition includes carefully controlled carbon content and strategic alloying elements that enhance wear properties without compromising weldability for field repairs.

Superior Wear Life Performance Through Advanced Metallurgy

Exceptional wear life represents the primary advantage of the Dozer Edge-Cutting 11156585, achieved through sophisticated metallurgical engineering and quality control processes. Independent testing demonstrates wear life improvements ranging from 25% to 40% compared to conventional cutting edges under similar operating conditions. The enhanced wear resistance stems from several key metallurgical innovations that set this cutting edge apart from standard alternatives:

- Optimized Carbide Structure: Controlled cooling processes create uniform carbide distribution throughout the steel matrix, providing consistent wear resistance across the entire cutting surface while preventing localized wear patterns that reduce overall edge life.

- Refined Grain Structure: Advanced heat treatment protocols achieve fine-grain steel structure that enhances both hardness and impact resistance, allowing the edge to withstand severe operating conditions without premature failure or edge deterioration.

- Strategic Alloy Composition: Precisely balanced chromium, molybdenum, and vanadium content creates optimal hardness levels while maintaining the flexibility needed to absorb impact forces encountered during heavy cutting operations.

These metallurgical advantages translate directly into extended operational cycles between replacements, reducing both parts costs and labor expenses associated with frequent edge changes. The enhanced wear life also maintains cutting efficiency longer, preserving fuel economy and productivity throughout the service life.

Minimizing Downtime Through Reliable Performance

Downtime reduction represents a critical economic benefit of the Dozer Edge-Cutting 11156585, as unplanned maintenance interruptions can cost thousands of dollars per hour in lost productivity. This cutting edge significantly reduces downtime through multiple reliability enhancements designed to prevent unexpected failures. The robust construction methodology eliminates common failure modes that plague standard cutting edges. Enhanced fatigue resistance prevents stress cracking at attachment points, while improved impact resistance reduces damage from rocks and debris. These reliability improvements create predictable maintenance schedules that allow for planned replacement during scheduled maintenance windows. Field performance data indicates substantial reductions in emergency maintenance calls when contractors switch to the 11156585 cutting edge. The consistent performance characteristics allow operators to plan maintenance activities more effectively, avoiding rush replacement orders and expedited shipping costs that inflate total ownership expenses. Quality assurance protocols ensure consistent performance across production batches, eliminating variability that can lead to unexpected failures. Each cutting edge undergoes comprehensive testing to verify hardness specifications, dimensional accuracy, and metallurgical properties before shipment.

Comparative Analysis: Performance Advantages Over Market Alternatives

Market comparison reveals significant performance advantages when evaluating the Dozer Edge-Cutting 11156585 against both OEM and aftermarket alternatives. Cost-per-hour analysis demonstrates superior value despite potentially higher initial purchase prices. Performance testing under controlled conditions shows the 11156585 cutting edge maintains sharpness longer than conventional alternatives, preserving cutting efficiency throughout extended service intervals. This sustained performance reduces fuel consumption and cycle times compared to worn cutting edges that require higher pushing forces. Reliability statistics from fleet operators indicate measurably lower failure rates compared to standard cutting edges. The reduced failure frequency translates into lower inventory requirements and decreased emergency procurement costs. Warranty coverage provides additional protection against manufacturing defects, offering peace of mind for large fleet investments. User feedback from construction contractors consistently highlights the predictable wear patterns that facilitate maintenance planning. Unlike alternatives that may exhibit irregular wear or sudden failure, the 11156585 cutting edge provides clear wear indicators that allow timely replacement scheduling.

Strategic Procurement Considerations for Heavy Equipment Operations

Procurement professionals seeking reliable Dozer Edge-Cutting 11156585 supplier relationships benefit from understanding the complete value proposition beyond initial purchase price. Total cost of ownership calculations must include wear life extension, downtime reduction, and maintenance labor savings to accurately assess economic benefits. Authorized distribution networks ensure authentic product sourcing with full manufacturer support and warranty coverage. Direct relationships with qualified suppliers provide access to technical expertise, installation guidance, and troubleshooting support that maximizes performance and service life. Volume purchasing arrangements offer significant cost advantages for large fleet operators. Bulk ordering programs provide pricing incentives while ensuring adequate inventory levels for planned maintenance activities. Flexible payment terms accommodate varying cash flow requirements and budget cycles. Global shipping capabilities support international operations with reliable delivery schedules and comprehensive logistics coordination. Expedited shipping options provide emergency support when unexpected failures require immediate replacement to minimize downtime costs.

Installation Excellence and Maintenance Best Practices

Proper installation procedures are essential for achieving optimal performance from the Dozer Edge-Cutting 11156585. Correct mounting techniques ensure proper stress distribution and prevent premature failure at attachment points. Installation specifications include torque requirements, bolt grade recommendations, and inspection procedures that verify secure mounting. Routine maintenance practices significantly impact cutting edge service life and performance. Regular inspection schedules allow early detection of wear patterns or damage that could lead to unexpected failure. Cleaning procedures remove accumulated debris that can accelerate wear or create stress concentrations. Monitoring wear progression enables optimal replacement timing that maximizes service life without risking sudden failure. Visual inspection techniques help operators identify when cutting edges approach replacement intervals, allowing scheduled maintenance planning that avoids emergency situations. Proper storage and handling procedures preserve cutting edge quality during inventory periods. Protection from moisture and physical damage maintains material properties and prevents deterioration that could affect performance or service life.

Why Choose SINOBL for Your Cutting Edge Requirements?

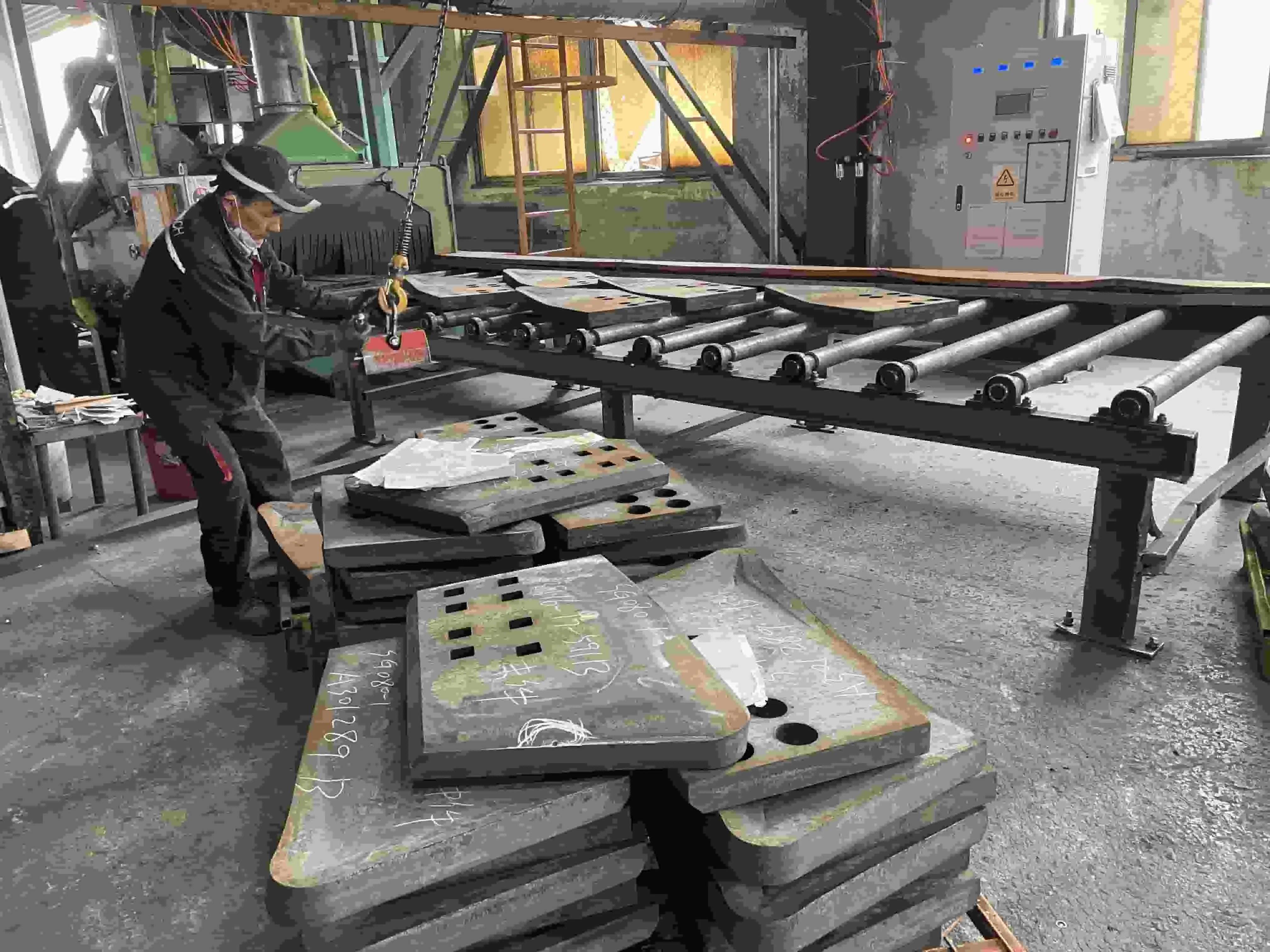

SINOBL stands as a trusted Dozer Edge-Cutting 11156585 manufacturer with proven expertise in heavy equipment wear parts manufacturing. Our commitment to quality excellence ensures every cutting edge meets stringent performance standards through comprehensive testing and quality control protocols. Our advanced manufacturing capabilities support high-volume production requirements while maintaining consistent quality across all products. With cutting edge production capacity reaching 2,500 tons monthly, we provide reliable supply chain support for large fleet operations and demanding project schedules. Extensive industry experience spanning diverse applications enables us to understand specific operational challenges and provide tailored solutions. Our technical team offers comprehensive support including application guidance, installation assistance, and performance optimization recommendations that maximize equipment productivity. Comprehensive OEM and ODM services accommodate custom requirements including dimensional modifications, specific hardness levels, and specialized coatings. Flexible customization options ensure optimal fit and performance for unique applications while maintaining our quality standards.

Frequently Asked Questions

Q1: What dozer models are compatible with the 11156585 cutting edge?

A: The Dozer Edge-Cutting 11156585 is designed to fit multiple CAT dozer models and other major equipment brands. Our engineering team can verify compatibility for specific equipment models and provide dimensional confirmation to ensure proper fit and performance.

Q2: How does the wear life compare to standard OEM cutting edges?

A: Independent testing demonstrates 25% to 40% longer wear life compared to conventional cutting edges under similar operating conditions. The actual improvement depends on soil conditions, operating practices, and maintenance procedures, but consistent performance advantages are documented across diverse applications.

Q3: What warranty coverage is provided with the 11156585 cutting edge?

A: SINOBL provides comprehensive warranty coverage against manufacturing defects and material failures. Warranty terms include replacement or credit for defective parts, with coverage duration varying based on order quantity and application requirements.

Partner with SINOBL for Enhanced Equipment Performance

SINOBL delivers exceptional value through our advanced Dozer Edge-Cutting 11156585 solutions that combine superior wear life with reduced downtime costs. Our proven manufacturing expertise and quality commitment ensure reliable performance that enhances fleet productivity and reduces total ownership expenses.

Our comprehensive support services include technical consultation, application engineering, and ongoing performance monitoring that optimizes cutting edge selection and maintenance practices. With over 3,000 tons of inventory available for immediate shipment, we provide reliable supply chain support for urgent requirements and planned maintenance activities.

Experience the SINOBL advantage through our customer-focused approach that prioritizes performance, reliability, and service excellence. Our global distribution network ensures consistent product availability and technical support regardless of project location. Contact us at nancy@sunmach.com.cn to discuss your specific requirements and discover how our cutting edge solutions can enhance your equipment performance while reducing operational costs.

Conclusion

The Dozer Edge-Cutting 11156585 represents a significant advancement in cutting edge technology, delivering measurable improvements in wear life and downtime reduction that translate into substantial cost savings for heavy equipment operations. Advanced metallurgical engineering and precision manufacturing ensure consistent performance advantages over conventional alternatives. SINOBL's commitment to quality excellence and comprehensive customer support makes us the preferred partner for procurement professionals seeking reliable cutting edge solutions that enhance fleet productivity and reduce total ownership costs.