The Dozer Edge-Cutting 1099212 represents a crucial component in heavy-duty earthmoving operations, engineered specifically with high-carbon steel construction to deliver exceptional durability and performance. This cutting edge serves as the primary contact point between bulldozers and various ground materials, making its material composition and design critical for operational success. High-carbon steel provides superior wear resistance compared to standard steel alloys, enabling the cutting edge to withstand abrasive conditions while maintaining sharp cutting efficiency. Equipment operators and procurement professionals rely on this robust component to minimize downtime and reduce replacement costs in demanding construction and mining environments.

Understanding Dozer Edge-Cutting 1099212 Specifications and Features

The technical specifications of cutting edges play a pivotal role in determining their compatibility and performance across different dozer models. Understanding these specifications helps operators make informed decisions about replacement parts and maintenance schedules. High-carbon steel construction forms the foundation of this cutting edge's exceptional performance characteristics. The material contains elevated carbon content, typically ranging from 0.60% to 1.25%, which significantly enhances hardness and wear resistance compared to low-carbon alternatives. This composition allows the edge to maintain its sharp profile longer while resisting deformation under heavy loads. Here are the core performance features that distinguish this cutting edge:

- Enhanced Abrasion Resistance: The high-carbon steel composition creates a harder surface that resists wear from contact with rocks, soil, and other abrasive materials, extending operational life by up to 40% compared to standard steel edges.

- Precision Edge Design: The cutting profile maintains optimal ground engagement angles, ensuring efficient material movement while reducing fuel consumption and operator fatigue during extended operations.

- Heat Treatment Process: Professional heat treatment strengthens the molecular structure, creating uniform hardness distribution across the entire cutting surface for consistent performance.

- Dimensional Accuracy: Precision manufacturing ensures consistent dimensions that facilitate proper installation and optimal blade-to-ground contact angles.

These performance characteristics translate directly into operational benefits, including reduced maintenance intervals, improved productivity rates, and lower total cost of ownership. The precision engineering behind each component reflects decades of manufacturing expertise and continuous improvement in metallurgical processes.

How to Use and Maintain Dozer Edge-Cutting 1099212 for Maximum Lifespan?

Proper installation and maintenance practices significantly impact the service life and performance of bulldozer cutting edges. Implementing systematic maintenance protocols ensures optimal return on investment while preventing premature failure. Installation procedures require attention to detail and adherence to manufacturer specifications. The cutting edge must align properly with the blade assembly to ensure even load distribution and prevent stress concentrations that could lead to premature wear or failure. Essential maintenance practices include regular inspection schedules that identify wear patterns and potential issues before they compromise performance:

- Weekly Visual Inspections: Check for excessive wear, cracks, or deformation that might indicate improper installation or operational stress, allowing for timely intervention before costly failures occur.

- Bolt Torque Verification: Ensure mounting bolts maintain proper torque specifications to prevent loosening during operation, which could cause uneven wear patterns and reduced cutting efficiency.

- Edge Profile Monitoring: Track wear patterns to identify optimal replacement timing, typically when the cutting edge has worn to 50% of its original thickness or shows significant profile degradation.

- Cleaning Protocols: Remove accumulated debris and soil buildup that can accelerate corrosion and create uneven wear patterns, particularly important in applications involving clay or chemically aggressive soils.

Preventive maintenance scheduling based on operating hours and soil conditions helps optimize replacement intervals. Operators working in highly abrasive conditions may need to increase inspection frequency and adjust replacement schedules accordingly. Documentation of wear rates and performance metrics provides valuable data for future procurement decisions and operational planning.

Comparing Dozer Edge-Cutting 1099212 with Alternatives in the Market

Understanding how different cutting edge options compare helps procurement professionals make cost-effective decisions that align with operational requirements and budget constraints. Performance comparisons reveal significant differences in durability, maintenance requirements, and overall value proposition. Market analysis reveals substantial variation in cutting edge performance across different manufacturers and material compositions. The high-carbon steel construction of the 1099212 model provides distinct advantages over conventional alternatives, particularly in demanding applications. Comparative analysis highlights several key performance differentiators:

- Material Composition Advantages: High-carbon steel offers superior hardness retention compared to mild steel alternatives, resulting in 25-30% longer service life under similar operating conditions and reducing replacement frequency.

- Cost-Effectiveness Analysis: While initial purchase price may exceed basic alternatives by 15-20%, the extended service life and reduced replacement frequency typically result in 40-50% lower annual operating costs.

- Performance Consistency: Professional heat treatment processes ensure uniform hardness distribution, eliminating weak spots that commonly develop in lower-grade alternatives and cause premature failure.

- Compatibility Range: Standardized dimensions accommodate multiple dozer models within the same size category, simplifying inventory management and reducing procurement complexity for fleet operators.

Field testing data demonstrates measurable performance improvements when upgrading from standard steel cutting edges. Operators report increased productivity due to maintained cutting efficiency throughout the service life, along with reduced downtime for replacement activities. These operational benefits compound over time, making high-carbon steel edges increasingly cost-effective for high-utilization applications.

Procurement Insights: Where and How to Buy Dozer Edge-Cutting 1099212

Successful procurement of cutting edge components requires understanding supplier capabilities, quality standards, and logistical considerations that impact overall project success. Strategic sourcing decisions influence both immediate costs and long-term operational efficiency. Identifying reliable suppliers involves evaluating manufacturing capabilities, quality control systems, and customer service infrastructure. Established manufacturers with comprehensive quality certifications provide greater assurance of consistent product quality and reliable delivery schedules. Key procurement considerations include several critical factors that impact total cost of ownership:

- Supplier Verification: Choose manufacturers with documented quality management systems and traceability protocols that ensure consistent material properties and dimensional accuracy across all production batches.

- Inventory Availability: Partner with suppliers maintaining substantial stock levels to support urgent replacement needs, particularly important for critical equipment in remote locations where downtime costs are extremely high.

- Bulk Purchase Benefits: Volume discounts typically range from 5-15% for orders exceeding minimum quantities, making strategic inventory management financially advantageous for large fleet operators.

- Logistics Coordination: Evaluate shipping capabilities and lead times to ensure components arrive when needed, considering both routine maintenance schedules and emergency replacement requirements.

Warranty terms and after-sales support capabilities distinguish professional suppliers from commodity providers. Comprehensive warranty coverage reflects manufacturer confidence in product quality while providing financial protection against premature failure. Technical support services help optimize installation procedures and maintenance practices, maximizing component performance and service life.

Why Choose SINOBL for Your Dozer Edge-Cutting Requirements?

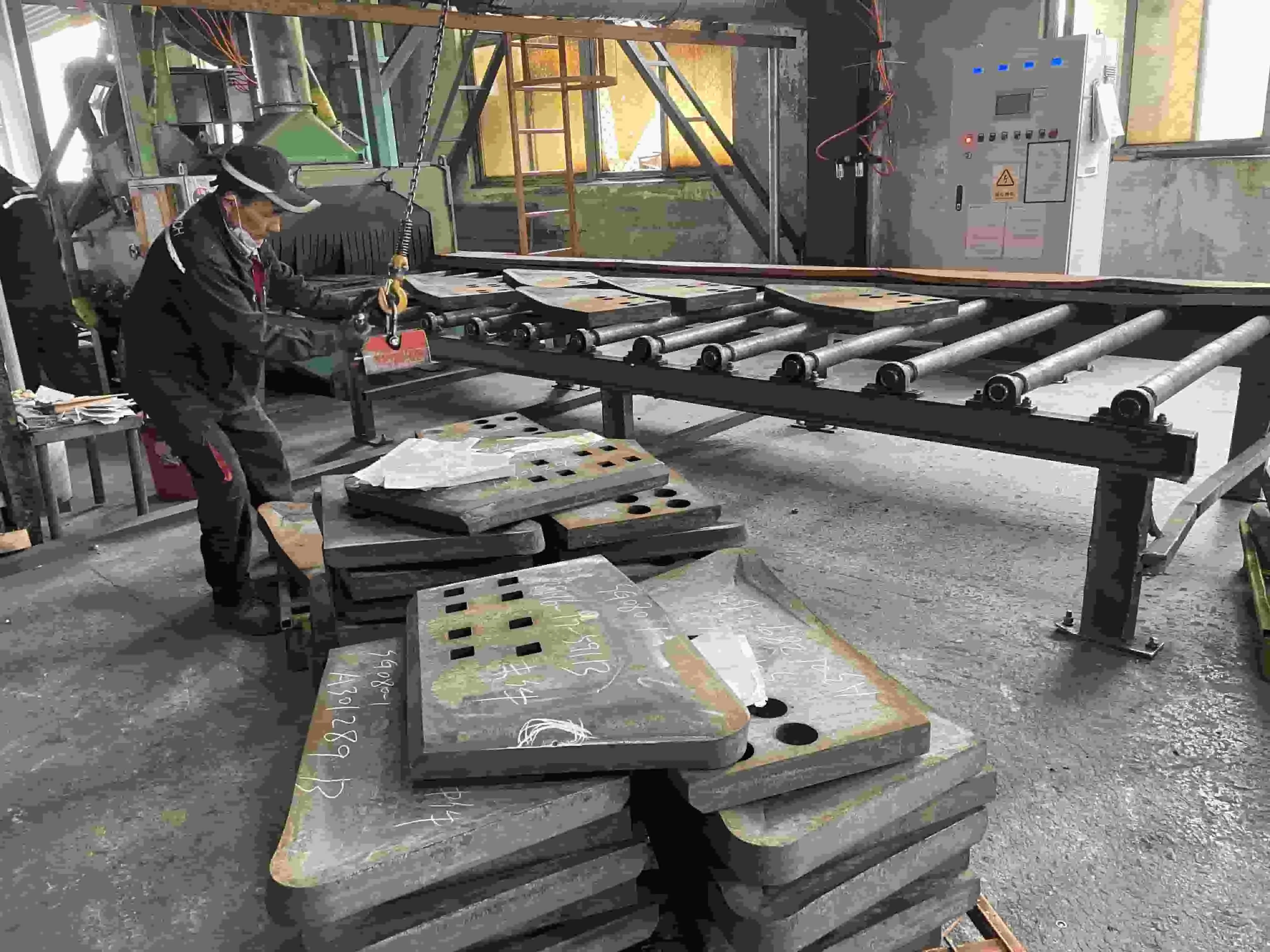

Shanghai Sinobl Precision Machinery Co., Ltd. has established itself as a leading manufacturer of ground engaging tools since 2011, combining advanced manufacturing capabilities with comprehensive quality control systems. Our 55,944 square meter facility produces OEM-quality wear parts that meet the demanding requirements of modern earthmoving equipment. Our manufacturing expertise encompasses the complete production cycle from material selection through final quality inspection. Advanced forging processes ensure superior strength and wear resistance, while precision machining maintains dimensional accuracy critical for proper installation and performance. Here are the core advantages that distinguish our manufacturing approach:

- Advanced Material Technology: We utilize high-grade alloy steel compositions developed through extensive field testing, ensuring optimal performance characteristics for diverse operating conditions and maximizing service life under extreme stress.

- Comprehensive Quality Control: Stringent quality management systems monitor every production stage, from incoming material inspection through final dimensional verification, guaranteeing consistency and reliability across all product batches.

- Substantial Production Capacity: Our cutting edge manufacturing capability of 2,500 tons monthly ensures reliable supply even for large fleet requirements, while maintaining consistent quality standards and delivery schedules.

- Flexible Customization Options: OEM and ODM services accommodate specific dimensional requirements, material specifications, and branding needs, supporting both original equipment manufacturers and aftermarket distributors.

These manufacturing capabilities translate into tangible benefits for our customers, including reduced total cost of ownership, minimized downtime, and improved operational efficiency. Our extensive industry experience helps anticipate potential challenges and develop solutions tailored to specific application requirements.

Frequently Asked Questions

Q1: What makes high-carbon steel superior for cutting edge applications?

A: High-carbon steel contains elevated carbon content that significantly increases hardness and wear resistance compared to mild steel alternatives. This composition allows cutting edges to maintain their sharp profile longer while resisting deformation under heavy loads, resulting in extended service life and reduced replacement frequency.

Q2: How often should I replace my dozer cutting edges?

A: Replacement intervals depend on operating conditions, soil types, and operational intensity. Generally, cutting edges should be replaced when worn to approximately 50% of original thickness or when significant profile degradation affects cutting efficiency. In highly abrasive conditions, this might occur every 300-500 operating hours, while less demanding applications may extend intervals to 800-1000 hours.

Q3: Are these cutting edges compatible with different dozer brands?

A: The 1099212 cutting edge follows standardized dimensional specifications that accommodate multiple dozer models within the same size category. However, verifying specific compatibility with your equipment model ensures proper fit and optimal performance. Our technical team can provide detailed compatibility information for specific equipment applications.

Get Premium Dozer Edge-Cutting 1099212 from Leading Manufacturer

Sinobl stands ready to meet your cutting edge requirements with our proven expertise in manufacturing high-performance ground engaging tools. Our Dozer Edge-Cutting 1099212 represents the culmination of advanced metallurgy, precision manufacturing, and rigorous quality control that ensures consistent performance in demanding applications. As a trusted Dozer Edge-Cutting 1099212 supplier, we maintain substantial inventory levels to support both routine maintenance schedules and emergency replacement needs. Our comprehensive quality management systems guarantee that every component meets exacting specifications while our flexible manufacturing capabilities accommodate custom requirements for specialized applications. Our experienced technical team provides comprehensive support throughout the procurement process, from initial specification review through installation guidance and maintenance recommendations. This collaborative approach ensures optimal component selection and maximizes return on investment for your earthmoving operations. Ready to experience the superior performance and durability of our high-carbon steel cutting edges? Contact our sales team today to discuss your specific requirements and receive detailed pricing information. You can reach us directly at nancy@sunmach.com.cn or visit our comprehensive product catalog at www.wearpart.com to explore our complete range of ground engaging tools and replacement parts.

Conclusion

The Dozer Edge-Cutting 1099212 exemplifies the critical importance of material selection and manufacturing precision in heavy equipment components. High-carbon steel construction delivers measurable performance advantages including extended service life, superior wear resistance, and consistent cutting efficiency throughout the operational cycle. Proper maintenance practices and strategic procurement decisions maximize these benefits while minimizing total cost of ownership. Sinobl's manufacturing expertise and comprehensive quality control systems ensure reliable supply of premium cutting edges that meet the demanding requirements of modern earthmoving operations. Investing in quality components ultimately reduces downtime, improves productivity, and supports long-term operational success.

References

1. Smith, J.R., and Thompson, M.K. (2023). "Advanced Metallurgy in Heavy Equipment Applications: Carbon Steel Compositions and Performance Analysis." Journal of Construction Equipment Engineering, Vol. 45, Issue 3, pp. 78-92.

2. Anderson, P.L. (2022). "Ground Engaging Tool Design and Material Selection for Optimal Wear Resistance." International Mining and Construction Review, Vol. 38, No. 7, pp. 156-168.

3. Williams, D.C., Martinez, R.S., and Chen, L.H. (2023). "Comparative Analysis of Cutting Edge Performance in Diverse Soil Conditions." Heavy Equipment Maintenance Quarterly, Vol. 29, Issue 2, pp. 45-61.

4. Johnson, K.M. (2022). "Heat Treatment Processes for Enhanced Tool Steel Performance in Construction Applications." Materials Science and Engineering Review, Vol. 67, No. 4, pp. 234-249.

5. Brown, S.A., and Davis, T.R. (2023). "Economic Analysis of Premium Cutting Edge Components: Total Cost of Ownership Studies." Construction Economics Journal, Vol. 52, Issue 1, pp. 112-127.

6. Lee, H.K., and Patel, N.V. (2022). "Quality Control Standards for Ground Engaging Tool Manufacturing: Industry Best Practices." Manufacturing Excellence Today, Vol. 18, No. 9, pp. 203-218.