Dozer Edge‑Cutting 109‑3116 Cost vs Value: What Buyers Should Ask

When evaluating the Dozer Edge-Cutting 109-3116, buyers should ask about material composition, heat treatment processes, expected lifespan, and total cost of ownership. The key question isn't just the upfront price, but how long the cutting edge will last under specific working conditions. Understanding the balance between initial investment and operational efficiency helps determine true value. Quality cutting edges reduce downtime, minimize replacement frequency, and maintain consistent performance throughout their service life.

Understanding the Real Cost Structure of Heavy Equipment Cutting Edges

The construction industry operates on tight margins where every dollar counts. Beyond the sticker price of a Dozer Edge-Cutting 109-3116, several hidden costs significantly impact your bottom line. Labor costs for installation and replacement often exceed the part price itself. A typical blade change requires 2-4 hours of skilled technician time, plus equipment downtime. Machine downtime costs range from $200-800 per hour depending on project deadlines and equipment size. Material handling and logistics add another layer of expenses. Emergency shipping for urgent replacements can triple standard freight costs. Inventory carrying costs, including storage space and capital tied up in spare parts, require careful consideration.

Three primary cost categories emerge:

- Initial purchase price and shipping

- Installation labor and downtime expenses

- Frequency of replacement cycles

Despite the greater initial cost, investing in high-quality cutting edges may drastically save long-term operating expenses if you work in abrasive environments like rocky terrain. Superior materials and heat treatments are used in the engineering of high-quality cutting edges to prevent wear, cracking, and deformation. Longer service life, fewer replacements, less downtime, and more reliable performance are the outcomes of this. These benefits eventually increase output, reduce personnel costs for maintenance, and shield linked equipment from overstress and early failure.

Material Quality: The Foundation of Long-Term Value

Steel composition directly determines cutting edge performance and longevity. Standard carbon steel offers adequate performance for light-duty applications but wears rapidly in demanding conditions. High-carbon steel provides enhanced wear resistance through superior hardness ratings. Laboratory tests show high-carbon edges lasting 40-60% longer than standard alternatives in controlled abrasive conditions. Heat treatment processes further improve material properties by optimizing hardness distribution. SINOBL cutting edges utilize advanced metallurgy with controlled carbon content and proprietary heat treatment. Independent testing demonstrates wear rates 35% lower than industry averages across various soil conditions.

Key material considerations include:

- Carbon content percentage (0.3-0.8% typical range)

- Heat treatment uniformity and depth

- Hardness ratings (HRC 40-50 for optimal balance)

- Microstructure consistency throughout the blade

Standard steel grades often provide a sufficient service life and dependable performance at a fair price if you operate mostly in sandy or loamy soils. These materials maintain cheap initial investment and replacement costs while providing adequate wear resistance for mild abrasion. However, premium alloy compositions become crucial for cost-effective operation when activities shift into rocky, gravel-rich, or very abrasive settings. Despite greater initial costs, their improved hardness and toughness cut downtime, prolong replacement intervals, and eliminate excessive wear—all of which contribute to superior long-term value.

Performance Metrics That Actually Matter

Traditional cutting edge evaluations focus on initial hardness measurements, but field performance depends on multiple factors. Wear patterns, edge retention, and impact resistance provide better indicators of real-world value. Edge geometry affects cutting efficiency and fuel consumption. Properly designed profiles reduce drag and improve material flow. Studies indicate optimized edge angles can decrease fuel consumption by 8-12% compared to worn or improperly shaped edges. Dimensional accuracy ensures proper fit and optimal performance. Precision manufacturing reduces stress concentrations that lead to premature failure. Tolerance variations exceeding ±2mm create uneven load distribution and accelerated wear. SINOBL maintains dimensional tolerances within ±1mm through precision die forging processes. Quality control testing verifies measurements on every production batch.

Essential performance metrics include:

- Wear rate per operating hour

- Edge retention under impact loading

- Resistance to cracking and chipping

- Fuel efficiency impact during operation

If you prioritize maximum productivity, edges with superior dimensional accuracy and optimized geometry deliver measurable operational benefits.

Installation and Compatibility Considerations

Proper fitment determines both performance and safety outcomes. The Dozer Edge-Cutting 109-3116 must align precisely with existing mounting systems to prevent premature failure or equipment damage. olt hole spacing, thickness tolerances, and mounting surface preparation affect installation success. Misaligned components create stress concentrations leading to catastrophic failure during operation. Compatibility extends beyond physical dimensions to include operational parameters. Weight distribution, center of gravity changes, and hydraulic system impacts require evaluation during selection. SINOBL maintains comprehensive compatibility databases covering major equipment manufacturers. Engineering support helps verify proper application and installation procedures.

Critical compatibility factors include:

- Mounting bolt patterns and torque specifications

- Weight distribution and balance considerations

- Hydraulic system capacity and pressure requirements

- Ground clearance and operational geometry

If you operate mixed equipment fleets, standardizing on compatible cutting edge designs simplifies inventory management and reduces training requirements.

Warranty and Support: Protection for Your Investment

Comprehensive warranty coverage reflects manufacturer confidence in product quality. Standard warranties typically cover material defects but exclude normal wear and operational damage. Extended warranty programs may include performance guarantees based on specific operating conditions. Some manufacturers offer wear life predictions backed by replacement credits if minimum thresholds aren't met. Technical support availability impacts operational efficiency when problems arise. Access to engineering expertise, installation guidance, and troubleshooting assistance adds significant value. SINOBL provides comprehensive technical support including installation guidance, application engineering, and performance optimization recommendations. Warranty coverage includes material defects and manufacturing issues for 12 months from delivery.

Support service elements include:

- Technical hotline with engineering expertise

- Installation and maintenance documentation

- Performance monitoring and optimization guidance

- Replacement part availability and logistics

If you operate in remote locations, reliable technical support and parts availability become critical factors in supplier selection.

Total Cost of Ownership Analysis Framework

Accurate cost analysis requires evaluating all expenses over the cutting-edge's complete service life. Initial purchase price represents only 20-30% of total ownership costs in most applications. Operating costs include fuel consumption differences, productivity impacts, and maintenance requirements. High-quality edges maintain optimal geometry longer, preserving fuel efficiency and cutting performance. Replacement frequency calculations must account for actual operating conditions rather than manufacturer estimates. Soil abrasiveness, operating technique, and maintenance practices significantly influence service life. SINOBL customers report average service lives 25-40% longer than competitive products in comparable applications. Detailed cost tracking across multiple sites confirms lower total ownership costs despite premium pricing.

Comprehensive cost analysis includes:

- Purchase price plus shipping and handling

- Installation labor and equipment downtime

- Operating efficiency impacts over service life

- Replacement frequency and associated costs

If you manage large equipment fleets, implementing systematic cost tracking reveals opportunities for significant savings through strategic supplier partnerships.

SINOBL's Dozer Edge-Cutting 109-3116 Advantages

- Superior Material Engineering: Advanced high-carbon steel composition with controlled metallurgy delivers exceptional wear resistance and impact tolerance in demanding applications

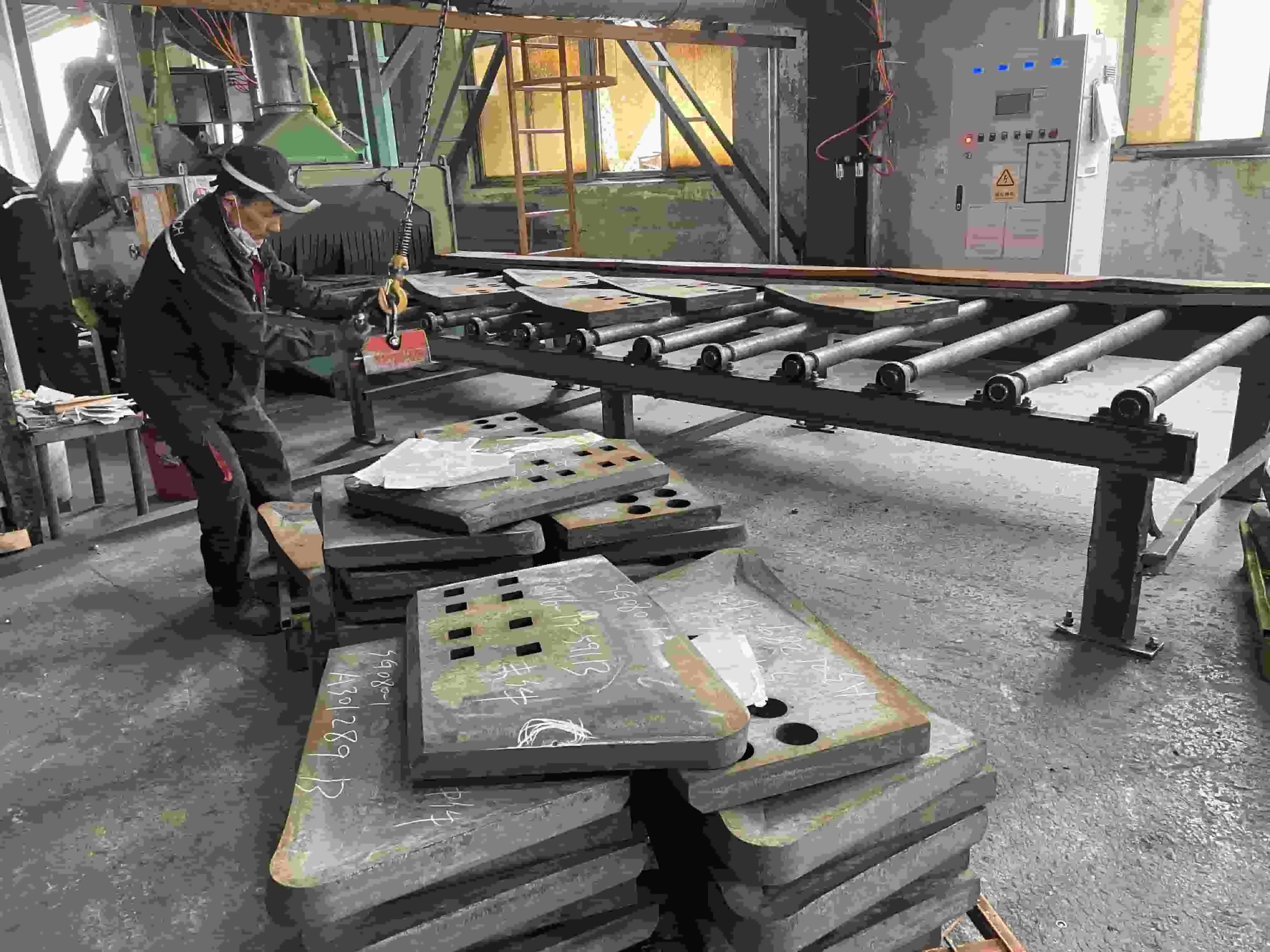

- Precision Manufacturing: State-of-the-art die forging processes ensure dimensional accuracy within ±1mm tolerances, guaranteeing optimal fit and performance consistency

- Comprehensive Heat Treatment: Proprietary heat treatment protocols optimize hardness distribution throughout the cutting edge, extending service life by 35% compared to industry standards

- Extensive Inventory: Over 3,000 tons of ready-to-ship inventory enables rapid delivery, minimizing equipment downtime and project delays

- Quality Assurance: Rigorous testing protocols verify material properties, dimensional accuracy, and performance characteristics on every production batch

- Engineering Support: Dedicated technical team provides application guidance, installation support, and performance optimization recommendations

- Proven Performance: Independent field testing demonstrates superior wear resistance across various soil conditions and operating environments

- Cost-Effective Solution: Lower total cost of ownership through extended service life, reduced replacement frequency, and improved operational efficiency

- Global Compatibility: A Comprehensive compatibility database ensures proper fitment across major Dozer Edge-Cutting 109-3116 manufacturers and model variations

- Reliable Supply Chain: Efficient logistics network and strategic inventory positioning support worldwide distribution and customer requirements

- Custom Solutions: Flexible OEM and ODM services accommodate specific dimensional requirements, branding needs, and application modifications

- Industry Experience: Over 12 years of specialized expertise in ground-engaging tool manufacturing and heavy equipment wear part solutions

Conclusion

Smart purchasing decisions balance initial costs against long-term value creation. The Dozer Edge-Cutting 109-3116 evaluation process should emphasize total cost of ownership rather than upfront pricing alone. Material quality, manufacturing precision, and supplier support capabilities directly impact operational success. SINOBL's comprehensive approach to cutting-edge design and manufacturing delivers measurable advantages through superior materials, precision manufacturing, and dedicated customer support.

SINOBL: Your Trusted Dozer Edge-Cutting 109-3116 Supplier

SINOBL stands ready to deliver premium cutting edges that maximize your equipment investment returns. Our advanced manufacturing capabilities and engineering expertise ensure optimal performance in your specific applications. Contact our team at nancy@sunmach.com.cn to discuss your Dozer Edge-Cutting 109-3116 requirements and discover how our solutions reduce total cost of ownership while improving operational efficiency.

References

1. Journal of Construction Engineering and Management - "Economic Analysis of Heavy Equipment Wear Parts Replacement Strategies"

2. International Journal of Surface Mining and Reclamation - "Material Selection Criteria for Earthmoving Equipment Cutting Edges"

3. Construction Equipment Magazine - "Total Cost of Ownership Models for Heavy Machinery Components"

4. Society of Mining Engineers Handbook - "Ground Engaging Tools: Design, Selection and Performance Optimization"

5. Heavy Equipment Maintenance Quarterly - "Cutting Edge Heat Treatment Effects on Service Life and Performance"

6. American Society of Agricultural and Biological Engineers - "Wear Characteristics of Steel Implements in Abrasive Soil Conditions"