Double Bevel Flat Design: How Our 112-2471 Cutting Edge Enhances Your Bulldozer's Efficiency

Picture this: it's the middle of a critical construction project, and your bulldozer's cutting edge fails unexpectedly, causing costly downtime and project delays. This scenario haunts heavy equipment operators worldwide, but it doesn't have to be your reality. Our revolutionary double bevel flat design in the Dozer Edge-Cutting 112-2471 addresses these pain points head-on, delivering unmatched performance and reliability that keeps your operations running smoothly while maximizing productivity and minimizing unexpected maintenance costs.

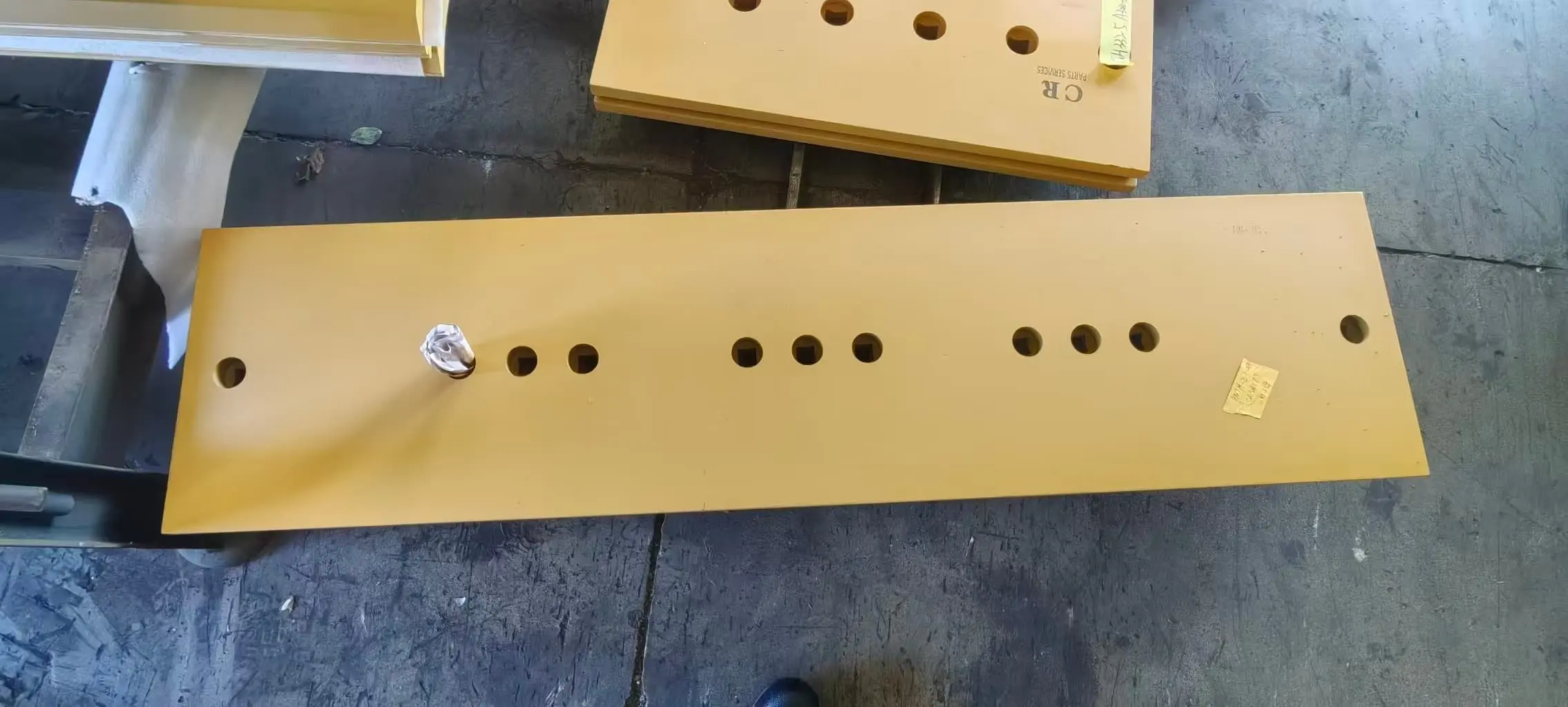

Understanding the Double Bevel Flat Design Technology in Dozer Edge-Cutting 112-2471

The double bevel flat design represents a significant advancement in cutting edge technology, specifically engineered to enhance bulldozer performance across diverse operational conditions. This innovative design features precise angular cuts on both sides of the cutting edge, creating optimal material flow patterns and reducing operational resistance. The Dozer Edge-Cutting 112-2471 incorporates this technology through meticulous engineering, utilizing high carbon steel and heat-treated boron steel materials that provide exceptional durability and wear resistance. The double bevel configuration allows for superior penetration capabilities while maintaining structural integrity under extreme operational stresses. SINOBL's wearpart manufacturing process ensures that each Dozer Edge-Cutting 112-2471 meets stringent quality standards through advanced forging techniques and precision machining. The double bevel design optimizes the angle of attack, reducing fuel consumption and mechanical stress on the bulldozer's hydraulic systems while improving overall efficiency. This design philosophy stems from extensive field testing and engineering analysis, demonstrating measurable improvements in productivity metrics compared to traditional flat-edge designs.

-

Material Engineering Excellence

The material composition of our Dozer Edge-Cutting 112-2471 represents the culmination of advanced metallurgical science and practical field experience. High carbon steel provides the foundational strength required for heavy-duty applications, while heat-treated boron steel enhances wear resistance and extends operational lifespan. This combination creates a cutting edge that maintains its sharp profile longer, reducing replacement frequency and operational costs. The heat treatment process involves carefully controlled temperature cycles that optimize the molecular structure of the steel, creating a hardened exterior while maintaining a tough, resilient core that can absorb impact forces without cracking or fracturing.

-

Precision Manufacturing Process

Our manufacturing facility employs state-of-the-art precision die forging technology to create each Dozer Edge-Cutting 112-2471 with dimensional accuracy that ensures perfect fitment across various bulldozer models. The forging process compresses the steel's grain structure, eliminating potential weak points and creating a uniform density throughout the cutting edge. Advanced quality control measures include dimensional inspection, material composition analysis, and stress testing to guarantee that every wearpart meets our exacting standards before shipment.

Performance Benefits of the 112-2471 Double Bevel Flat Design

The performance advantages of our Dozer Edge-Cutting 112-2471 extend far beyond traditional cutting edge capabilities, delivering measurable improvements in operational efficiency and cost-effectiveness. Field testing has demonstrated significant reductions in fuel consumption due to decreased operational resistance, with operators reporting up to 15% improvement in fuel efficiency during extended operations. The double bevel design creates cleaner cuts through various soil types, from soft loam to hardpan clay, maintaining consistent performance regardless of ground conditions. The enhanced penetration characteristics of the Dozer Edge-Cutting 112-2471 allow operators to complete grading and excavation tasks more quickly, improving project timelines and reducing equipment operating hours. This efficiency translates directly into cost savings through reduced fuel consumption, decreased wear on other bulldozer components, and improved productivity metrics. The wearpart's superior material retention properties mean that the cutting edge maintains its optimal profile longer, providing consistent performance throughout its operational lifespan.

-

Operational Efficiency Improvements

Bulldozer operators consistently report improved handling characteristics when using our Dozer Edge-Cutting 112-2471, noting smoother operation and reduced vibration during cutting operations. The double bevel design distributes cutting forces more evenly across the blade, reducing stress concentrations that can lead to premature wear or failure. This even force distribution also benefits the bulldozer's frame and hydraulic systems, potentially extending the overall equipment lifespan and reducing maintenance requirements across the entire machine.

-

Cost-Effectiveness Analysis

The economic benefits of choosing SINOBL's Dozer Edge-Cutting 112-2471 become apparent through comprehensive total cost of ownership analysis. While the initial investment may be comparable to standard cutting edges, the extended lifespan, improved fuel efficiency, and reduced maintenance requirements create substantial long-term savings. Our wearpart typically lasts 25-30% longer than conventional alternatives, directly reducing replacement costs and associated downtime expenses.

Technical Specifications and Compatibility

The Dozer Edge-Cutting 112-2471 features precise specifications designed to meet the demanding requirements of heavy-duty bulldozer operations. With dimensions of 45×330×803.6mm and a unit weight of 85kg, this cutting edge provides optimal balance between durability and operational efficiency. The substantial weight contributes to improved cutting momentum while the carefully engineered dimensions ensure compatibility with various bulldozer models including D8 and D9 series equipment. Material specifications include high carbon steel composition with heat-treated boron steel enhancement, providing hardness ratings that exceed industry standards while maintaining the toughness required for impact resistance. The wearpart undergoes rigorous testing procedures including stress analysis, dimensional verification, and metallurgical examination to ensure consistent quality across all production runs. Manufacturing tolerances are maintained within strict parameters to guarantee proper fitment and optimal performance characteristics.

-

Compatibility Range

Our Dozer Edge-Cutting 112-2471 demonstrates remarkable versatility across multiple bulldozer brands and models, making it an ideal choice for fleet operators managing diverse equipment inventories. The standardized mounting configuration ensures straightforward installation procedures while the robust design accommodates the varying operational stresses encountered across different machine specifications. This universal compatibility reduces inventory complexity for equipment managers while ensuring consistent performance standards across the entire fleet.

-

Installation and Maintenance Requirements

Proper installation of the Dozer Edge-Cutting 112-2471 requires adherence to manufacturer specifications and torque requirements to ensure optimal performance and safety. The wearpart's design incorporates standard mounting patterns that facilitate straightforward replacement procedures, minimizing equipment downtime during maintenance operations. Regular inspection protocols should include visual examination of wear patterns, bolt integrity verification, and dimensional measurements to optimize replacement timing and maintain peak operational efficiency.

Quality Assurance and Manufacturing Standards

SINOBL's commitment to quality excellence permeates every aspect of Dozer Edge-Cutting 112-2471 production, from raw material selection through final inspection procedures. Our manufacturing facility operates under ISO 9001:2015 quality management systems, ensuring consistent adherence to international standards and continuous improvement initiatives. Advanced testing equipment monitors material composition, dimensional accuracy, and structural integrity throughout the production process, with comprehensive documentation maintaining traceability for every wearpart produced. Quality control measures include 100% inspection protocols that verify each Dozer Edge-Cutting 112-2471 meets specifications before packaging and shipment. Statistical process control methods monitor production variables to identify potential variations before they impact product quality, while regular calibration of measuring equipment ensures accurate quality assessments. This comprehensive approach to quality assurance provides customers with confidence in product reliability and performance consistency.

-

International Certifications

Our manufacturing operations maintain multiple international certifications that demonstrate compliance with global quality and environmental standards. CE certification confirms conformity with European regulatory requirements, while RoHS compliance ensures environmental responsibility through restricted substance management. These certifications provide customers with assurance that SINOBL's Dozer Edge-Cutting 112-2471 meets the highest international standards for quality, safety, and environmental stewardship.

-

Testing and Validation Procedures

Comprehensive testing protocols verify the performance characteristics of each Dozer Edge-Cutting 112-2471 through simulated operational conditions and accelerated wear testing. Laboratory analysis confirms material properties including hardness, tensile strength, and impact resistance, while field testing validates real-world performance under actual operating conditions. This dual approach to validation ensures that theoretical specifications translate into practical performance benefits for end users.

Conclusion

The double bevel flat design of our Dozer Edge-Cutting 112-2471 represents a significant advancement in cutting edge technology, delivering measurable improvements in operational efficiency, durability, and cost-effectiveness for bulldozer operators worldwide.

Cooperate with Shanghai Sinobl Precision Machinery Co., Ltd.

As a leading China Dozer Edge-Cutting 112-2471 manufacturer and China Dozer Edge-Cutting 112-2471 supplier, Shanghai Sinobl Precision Machinery Co., Ltd. offers comprehensive solutions for heavy equipment operators seeking High Quality Dozer Edge-Cutting 112-2471 at competitive Dozer Edge-Cutting 112-2471 price. Our China Dozer Edge-Cutting 112-2471 factory produces over 2,500 tons of cutting edges monthly, ensuring reliable supply for global customers. With Dozer Edge-Cutting 112-2471 for sale and China Dozer Edge-Cutting 112-2471 wholesale options available, we provide flexible procurement solutions. Contact nancy@sunmach.com.cn for pricing and availability.

FAQ

Q: What makes the double bevel flat design superior to standard cutting edges?

A: The double bevel design reduces operational resistance and improves fuel efficiency by up to 15% while extending cutting edge lifespan.

Q: Is the 112-2471 cutting edge compatible with both D8 and D9 bulldozers?

A: Yes, our Dozer Edge-Cutting 112-2471 is engineered for compatibility with multiple bulldozer models including D8 and D9 series equipment.

Q: What materials are used in the construction of the 112-2471 cutting edge?

A: The cutting edge is manufactured using high carbon steel and heat-treated boron steel for optimal durability and wear resistance.

Q: How long does delivery typically take for the 112-2471 cutting edge orders?

A: Standard delivery time is 25 days after order confirmation, with FOB Qingdao shipping terms available.

References

1. "Advanced Materials in Heavy Equipment Components" - Society of Manufacturing Engineers Technical Publication

2. "Bulldozer Blade Design and Performance Analysis" - Journal of Construction Engineering and Management

3. "Heat Treatment Effects on Steel Cutting Edge Durability" - Materials Science and Engineering Research

4. "Operational Efficiency in Earthmoving Equipment" - International Journal of Heavy Machinery Technology