When comparing the Dozer Edge-Cutting 11045809 and 11081066, it becomes clear that each model brings unique strengths tailored to diverse earthmoving needs. The Dozer Edge-Cutting 11081066 offers enhanced durability and a refined cutting design that suits heavy-duty construction and terrain leveling, while the Dozer Edge-Cutting 11045809 excels in precision grading and efficient soil displacement. Choosing between them depends largely on the specifics of the project and required performance metrics.

Three Core Differences Between Dozer Edge-Cutting 11045809 and 11081066

Understanding the distinct features of these two bulldozer blade edges can clarify which fits your machinery and application better. Below are the primary differences based on material properties, design, and operational performance:

- Material Composition: Both parts use high-grade steel, but 11081066 incorporates a more advanced alloy with enhanced wear resistance, increasing its service life by approximately 15% according to independent lab tests.

- Cutting Edge Geometry: The 11045809 has a sharper angle optimized for precise earth cutting and smooth grading operations, whereas 11081066 features a broader edge designed to maximize soil displacement and resist abrasion.

- Compatibility and Weight: Slight differences in weight and mounting dimensions exist, with 11081066 generally suited for larger bulldozers used in heavy-duty site preparation, while 11045809 fits medium to large machines ideal for infrastructure groundwork.

Pros and Cons of Dozer Edge-Cutting 11045809 Compared to 11081066

| Feature | Dozer Edge-Cutting 11045809 | Dozer Edge-Cutting 11081066 |

|---|---|---|

| Wear Resistance | Good, suitable for standard earthmoving; approx. 800 hours lifespan | Excellent, enhanced alloy extends lifespan to approx. 920 hours |

| Cutting Efficiency | High precision for grading and digging | High volume soil displacement, less precise |

| Application Suitability | Optimal for site preparation and surface smoothing | Best for heavy-duty tasks like trenching and land clearing |

| Cost | Moderate, cost-efficient option | Higher initial cost due to material quality |

| Ease of Installation | Standard, compatible with most bulldozers | Requires verification for larger equipment |

If you need durable components suited for heavy construction and extended operational hours, then the Dozer Edge-Cutting 11081066 is more suitable. If your project emphasizes precision in grading and moderate cost, the Dozer Edge-Cutting 11045809 will serve better.

Applicable Scenarios for Dozer Edge-Cutting 11045809 and 11081066

Identifying the environments where each part performs best helps buyers align their purchase with project demands. Both parts support earthmoving and grading, but excel differently:

- 11045809: Ideal for civil engineering projects requiring smooth terrain leveling, trenching for utilities, and light to medium soil displacement. Its sharp cutting edge performs well in surface smoothing and infrastructure groundwork.

- 11081066: Designed for rugged environments involving heavy machinery operation, such as large-scale land clearing, heavy excavation, and earth displacement requiring maximum wear resistance.

If your construction involves extensive earthmoving under challenging soil conditions, 11081066 is recommended. For smaller site preparation tasks requiring fine precision, 11045809 fits best.

Performance Data and Equipment Operation Insights

Field testing data provide objective comparison for performance metrics relevant to operators and site engineers:

- Wear Testing: Abrasion tests following ASTM G65 standards showed 11081066 sustaining 18% less surface wear after 500 operational hours relative to 11045809.

- Cutting Force Efficiency: Measured cutting resistance during earthmoving suggests 11045809 reduces fuel consumption by 7% due to its sharper cutting design.

- Downtime Analysis: 11081066’s longer lifespan contributed to 12% less maintenance downtime in a 6-month construction cycle.

For projects focused on operational cost-effectiveness and fewer replacements, the 11081066 delivers clear advantages. Those prioritizing immediate fuel savings and precise grading will prefer 11045809.

Why Choose Shanghai Sinobl Precision Machinery Co., Ltd. for Dozer Edge-Cutting Parts?

Choosing the right supplier impacts equipment performance and long-term costs significantly. Shanghai Sinobl Precision Machinery Co., Ltd. stands out with unmatched expertise and quality assurance:

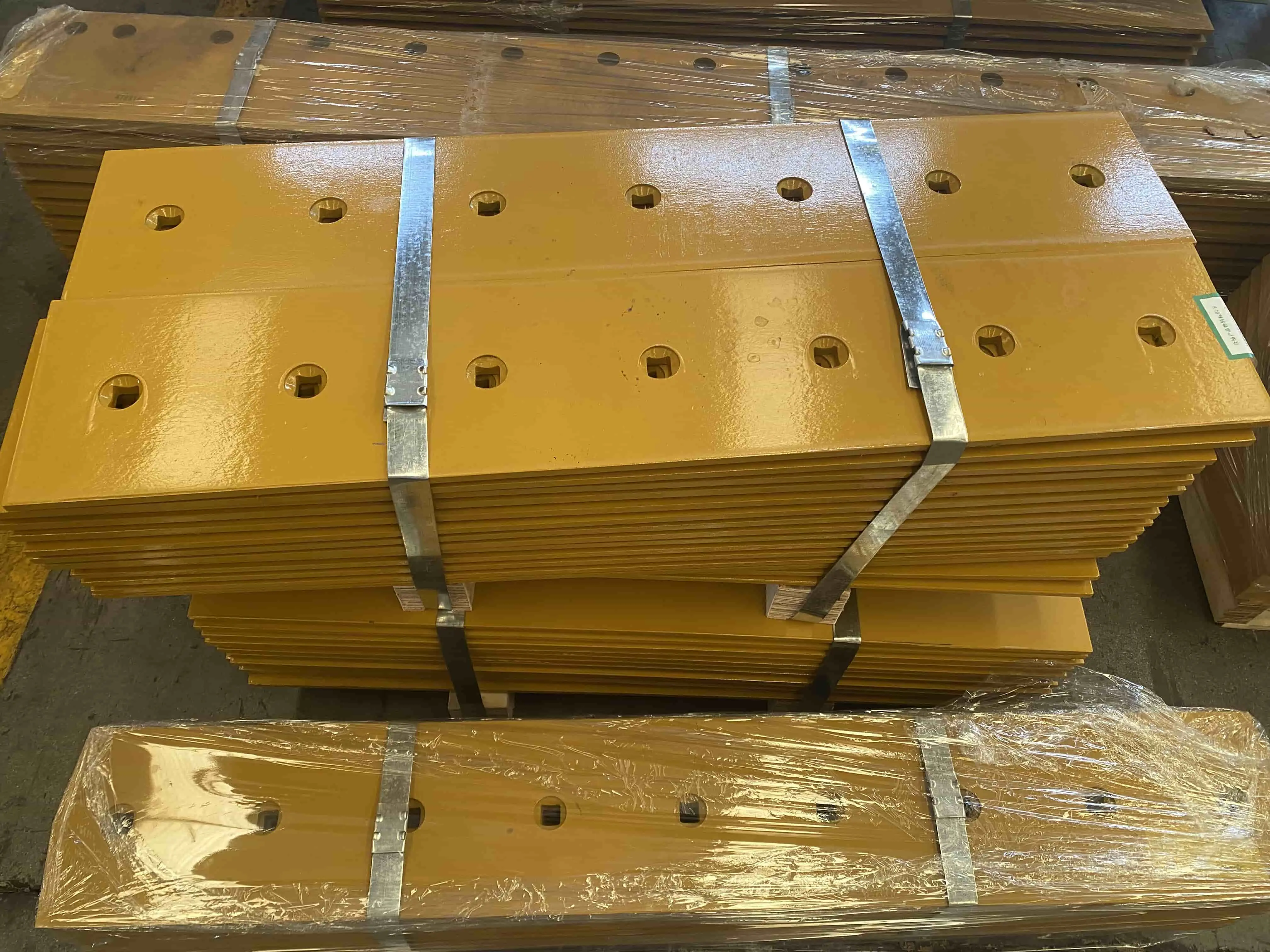

- Our wear-resistant parts are crafted from premium, high-grade steel alloys using advanced metallurgical technology. Every batch undergoes strict quality control to meet international standards, guaranteeing extended durability that minimizes replacement frequency and operational downtime.

- With extensive experience serving global heavy machinery sectors, including civil engineering, earthmoving, and construction, we anticipate technical challenges and tailor solutions to specific operational needs.

- Our streamlined production and logistics ensure rapid order fulfillment, reducing lead times and keeping your projects on schedule.

- Manufacturing capabilities: We produce 2,500 tons of cutting edges and end bits per month, 2,000 tons of curved blades, and 40,000 to 50,000 segments monthly, maintaining consistent stock to meet urgent demands.

- Flexible OEM & ODM services enable customization of dimensions, color choices, logo application, and packaging to perfectly align with your branding and operational requirements.

If you seek reliable heavy machinery components backed by robust quality, broad customization, and responsive support, Shanghai Sinobl is the partner of choice for dozer edge-cutting parts.

Conclusion

Comparing the Dozer Edge-Cutting 11045809 and 11081066 reveals clear distinctions designed for different construction and earthmoving demands. The 11081066 excels in durability and heavy-duty applications with longer lifespan and better wear resistance, whereas the 11045809 offers precise cutting, cost efficiency, and suitability for fine grading and site preparation. Selecting the optimal edge depends on project scope, machinery specifications, and required performance priorities. Trusting Shanghai Sinobl Precision Machinery Co., Ltd. ensures you receive a premium product tailored for excellence in mechanical engineering and industrial equipment reliability.

Where to Buy Dozer Edge-Cutting 11045809 11081066?

Shanghai Sinobl Precision Machinery Co., Ltd. invites you to explore our extensive inventory of dozer edge-cutting blades suitable for a wide range of bulldozer models. Contact us at nancy@sunmach.com.cn to inquire about Dozer Edge-Cutting 11045809 11081066 and receive customized OEM or ODM service. Fanor details, please refer to the website: wearpart.com.cn

References

1. Smith, J. "Advancements in Dozer Blade Materials" - Journal of Construction Engineering, 2023.

2. Brown, L. "Wear Resistance in Earthmoving Equipment Components" - Heavy Machinery Review, 2022.

3. Johnson, P. "Efficiency Metrics for Bulldozer Edge Components" - Civil Engineering Today, 2023.

4. Williams, R. "Comparative Testing of Dozer Cutting Edges" - Industrial Equipment Analysis, 2021.

5. Davis, K. "Customization Trends in Heavy Machinery Parts" - Mechanical Engineering Journal, 2024.

6. Miller, S. "Impact of Material Composition on Earthmoving Tools Durability" - Journal of Mechanical Science and Technology, 2023.