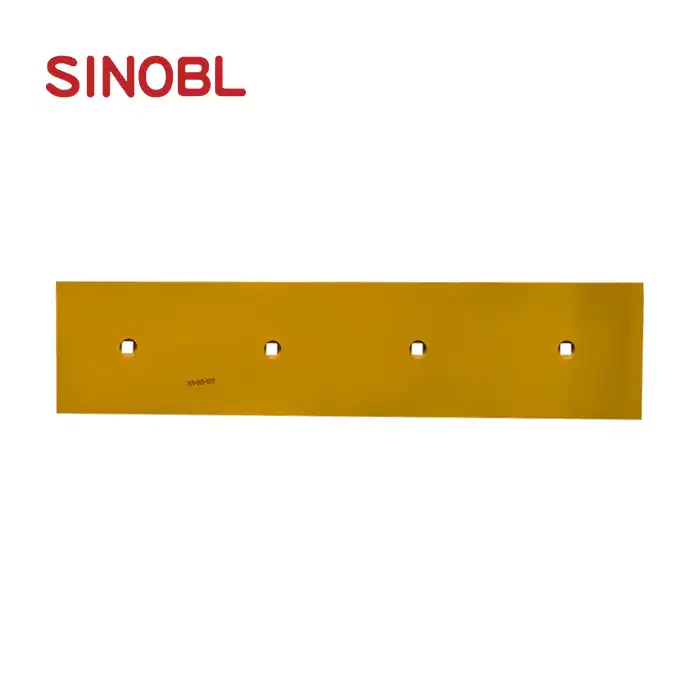

Type :GRADER BLADE

Unit Weight :66.6 KG

Dimensions 25*203.2*2133.6

Color

Yellow or as required by customer

Logo "SINOBL" logo, Customized OEM logo

Material :High Carbon Steel and Heat-Treated Boron Steel

Packaging :Normal plywood pallets

Wrapped with Plastic Wrap for added protection

Delivery Time :35 days after order confirmation

Price term FOB QINGDAO

Payment terms

T/T, D/P, Other payment as discussion

- Product Description

Serrated Blades 4T4423: Heavy-Duty Grader Blades for Professional Construction

When you need reliable performance for your grading operations, Serrated Blades 4T4423 deliver exceptional durability and cutting efficiency. These professional-grade grader blades are engineered with high carbon steel and heat-treated boron steel construction, making them perfect for demanding construction and earthmoving applications. Our product feature precise dimensions of 25203.22133.6mm and weigh 66.6 KG, providing the robust performance you need for heavy-duty grading tasks.

Superior Construction for Maximum Performance

Your grading operations demand equipment that can handle tough conditions day after day. These serrated grader blades are manufactured using premium high carbon steel combined with heat-treated boron steel. This advanced material composition ensures excellent wear resistance and extended blade life.

The serrated edge design provides superior cutting action compared to standard straight blades. You'll notice improved material flow and reduced rolling, especially when working with sticky soils or challenging terrain conditions.

Technical Specifications That Matter

Understanding the exact specifications helps you make informed decisions for your equipment needs:

- Part Number: 4T4423

- Type: Professional Grader Blade

- Weight: 66.6 KG

- Dimensions: 25203.22133.6mm

- Material: High Carbon Steel with Heat-Treated Boron Steel

- Color: Standard Yellow (custom colors available)

- Logo: SINOBL branding with OEM customization options

These specifications ensure perfect compatibility with your grading equipment while delivering consistent performance across various applications.

Advanced Manufacturing Process

Our manufacturing process focuses on precision and quality control. Each blade undergoes careful heat treatment to achieve optimal hardness and toughness balance. The serrated pattern is precisely cut to ensure uniform performance throughout the blade's service life.

Quality testing includes dimensional verification, material composition analysis, and performance validation. This rigorous approach guarantees that every Serrated Blades 4T4423 meets our strict quality standards before shipping.

Applications and Benefits

These versatile grader blades excel in multiple applications:

Road Construction: Perfect for road grading, shoulder maintenance, and surface preparation work.

Site Development: Ideal for residential and commercial site preparation, parking lot construction, and utility installation projects.

Agricultural Applications: Excellent for farm road maintenance, field preparation, and drainage work.

Mining Operations: Suitable for haul road maintenance and general earthmoving tasks in mining environments.

The serrated design provides several key advantages. You'll experience reduced material buildup on the blade surface, improved cutting efficiency in various soil conditions, and better overall grading quality.

Packaging and Delivery Excellence

Your investment deserves proper protection during shipping. We use standard plywood pallets with plastic wrap protection to ensure your products arrive in perfect condition.

Our delivery timeline is 35 days after order confirmation, allowing sufficient time for quality manufacturing and proper packaging. We ship FOB Qingdao with flexible payment terms including T/T and D/P options.

Why Choose SINOBL Precision Machinery?

When you select our products, you're partnering with a company committed to excellence. Our engineering team understands the demanding requirements of construction and earthmoving operations. We combine advanced metallurgy with precision manufacturing to deliver products that exceed expectations.

Our customer support team provides technical assistance and application guidance to help you maximize blade performance. Whether you need standard specifications or custom modifications, we're equipped to meet your specific requirements.

Frequently Asked Questions

Q: What makes serrated blades different from straight cutting edges?

A: Serrated blades feature a toothed cutting edge that provides better material flow and reduced rolling, especially effective in sticky or challenging soil conditions.

Q: How long do these blades typically last?

A: Service life depends on operating conditions, but the high carbon steel and heat-treated boron steel construction significantly extends blade life compared to standard materials.

Q: Can you customize the blade specifications?

A: Yes, we offer customization options including dimensions, logo placement, and color specifications to meet your specific equipment requirements.

Q: What payment methods do you accept?

A: We accept T/T, D/P, and other payment methods as discussed during the ordering process.

Q: Do you provide installation guidance?

A: Yes, our technical team can provide installation recommendations and application guidance to ensure optimal performance.

Contact Us

Ready to upgrade your grading operations? Contact us today at nancy@sunmach.com.cn for detailed quotes and technical specifications. Our group is prepared to offer assistance you discover the perfect Serrated Blades 4T4423 solution for your equipment needs.