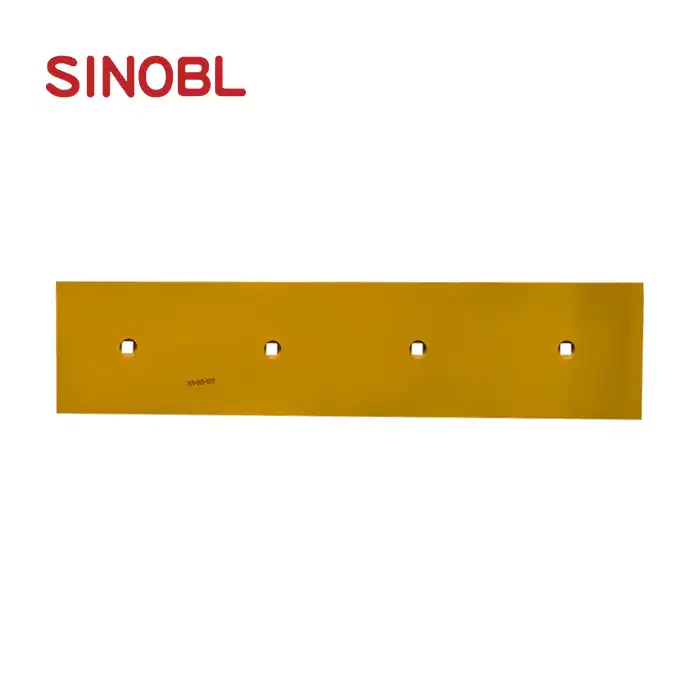

Type :GRADER BLADE

Unit Weight :30 KG

Dimensions 16*152.4*1828.8

Color

Yellow or as required by customer

Logo "SINOBL" logo, Customized OEM logo

Material :High Carbon Steel and Heat-Treated Boron Steel

Packaging :Normal plywood pallets

Wrapped with Plastic Wrap for added protection

Delivery Time :35 days after order confirmation

Price term FOB QINGDAO

Payment terms

T/T, D/P, Other payment as discussion

- Product Description

High-Performance Motor Grader Cutting Edges for Heavy Construction

When your grader faces tough terrain, you need reliable motor grader cutting edges that deliver exceptional performance. Our premium cutting edge solutions are engineered with high carbon steel and heat-treated boron steel, ensuring maximum durability for your heavy equipment operations. To satisfy the exacting standards of construction, road upkeep, and agricultural uses, every blade is put through a thorough quality testing process. We have been manufacturing product more than 13 years.

Product Introduction

Our Part No. 222-80-12001 grader blade represents cutting-edge engineering in heavy equipment wear parts. This sturdy cutting edge was created especially to withstand the most demanding construction conditions. The blade weighs 30 kg and has precise measurements of 16 x 152.4 x 1828.8 mm, giving your grader operations the ideal mix of strength and mobility.

Product Specifications

| Specification | Details |

|---|---|

| Part Number | 222-80-12001 |

| Type | Grader Blade |

| Weight | 30 KG |

| Dimensions | 16×152.4×1828.8mm |

| Material | High Carbon Steel and Heat-Treated Boron Steel |

| Color | Yellow (customizable) |

| Logo | SINOBL or Custom OEM |

| Delivery Time | 35 days after confirmation |

| Payment Terms | T/T, D/P, negotiable |

Usage Scenarios

Your grader cutting edges will excel in multiple demanding applications:

- Road Construction: Perfect for creating smooth, level surfaces on highways and municipal roads

- Site Preparation: Ideal for clearing and leveling construction sites before building begins

- Snow Removal: Effective for winter maintenance operations on roads and parking areas

- Agricultural Work: Excellent for farm road maintenance and field preparation

- Mining Operations: Suitable for haul road maintenance in mining environments

Product Features

Our cutting edges deliver superior performance through advanced engineering:

- Premium Materials: Heat-treated boron steel for increased durability combined with high carbon steel construction

- Precision Manufacturing: Consistent quality and performance are guaranteed by an eight-stage production proce

- Custom Compatibility: Designed to fit major grader models with exact specifications

- Extended Lifespan: Advanced heat treatment process significantly increases wear resistance

- Easy Installation: Engineered for quick and secure mounting on your equipment

Quality Control

Every motor grader cutting edges undergoes our comprehensive manufacturing process:

- Metal Production: Starting with premium raw materials

- Rolling: Precise shaping for optimal strength distribution

- Profiling: Exact dimensional accuracy for perfect fit

- Machining: Accurate finishing for seamless functioning

- Heat treatment: increased durability and hardness

- Shot Blasting: Superior surface preparation

- Painting: Protective coating for corrosion resistance

- Packaging: Secure plywood pallets with plastic wrap protection

Why Choose Us?

With our 55,944 sqm manufacturing facility, we deliver unmatched value:

- 13+ Years Experience: Established expertise since 2011 in wear parts manufacturing

- OEM Partnerships: Trusted supplier for domestic and international equipment manufacturers

- Research & Development: Independent material development ensures cutting-edge solutions

- Inventory Ready: Extensive stock levels for faster delivery times

- Complete Certification: Full compliance with industry standards and regulations

- Custom Solutions: OEM support with personalized branding options

Certifications

Our manufacturing processes and products meet stringent industry standards. We maintain comprehensive quality certifications to ensure your motor grader cutting edges meet the highest performance requirements.

FAQ

Q: What distinguishes your cutting edges from those of your rivals?

A: Our eight-stage production process, along with our exclusive blend of heat-treated boron steel and high carbon steel, results in exceptional performance and longevity.

Q: Can you customize dimensions for specific grader models?

A: In order to meet your precise needs, we do provide OEM services with unique dimensions, branding, and specs.

Q: How long does it usually take for you to deliver something?

A: Standard delivery is 35 days after order confirmation, while we reserve stock for speedier shipment when available.

Q: Do you offer assistance with installation?

A: Although we do not offer on-site installation, our technical staff provides comprehensive instructions and mounting specs.

Contact Us

Are you prepared to add high-end cutting edges to your grader? Our knowledgeable staff is here to assist you in choosing the ideal equipment solution. We are dedicated to providing outstanding quality and service, regardless of whether you require standard specs or unique OEM solutions.

Email:nancy@sunmach.com.cn

Get in touch today to discuss your requirements and discover how our motor grader cutting edges can enhance your equipment's performance and productivity.