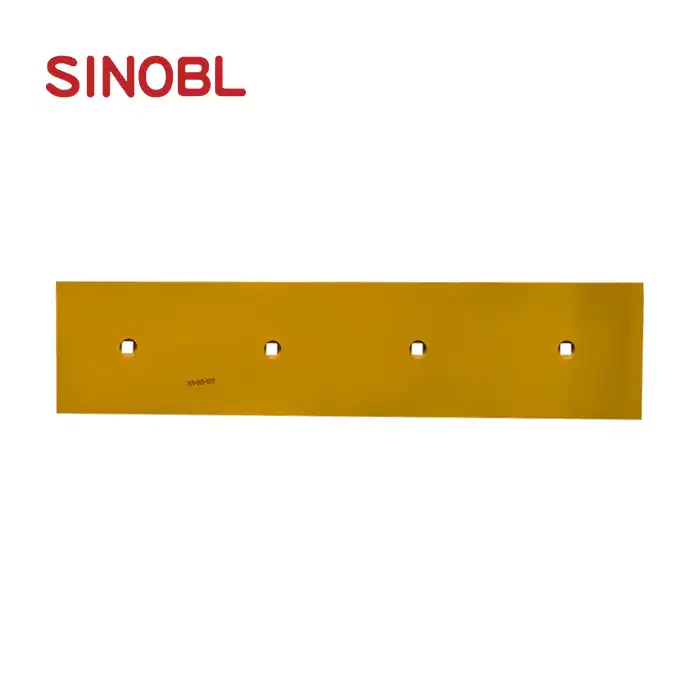

Type :GRADER BLADE

Unit Weight :42.8KG

Dimensions 19*203.2*1524

Color

Yellow or as required by customer

Logo "SINOBL" logo, Customized OEM logo

Material :High Carbon Steel and Heat-Treated Boron Steel

Packaging :Normal plywood pallets

Wrapped with Plastic Wrap for added protection

Delivery Time :35 days after order confirmation

Price term FOB QINGDAO

Payment terms

T/T, D/P, Other payment as discussion

- Product Description

Fransgard Grader Blade - Premium Replacement Parts for Superior Performance

When you need reliable replacement parts for your heavy equipment, our fransgard grader blade delivers exceptional performance and durability. Particularly designed for rigorous construction and road maintenance operations is Part No. 9W6252. You will value the exceptional materials and expert manufacturing that set this blade apart from the competition. This grader blade, which is made of heat-treated boron steel and high carbon steel, guarantees optimal productivity for your fleet's operations.

Product Specification

Our grader blade comes with comprehensive specifications designed to meet your exact requirements:

- Part Number: 9W6252

- Type: Grader Blade

- Unit Weight: 42.8KG

- Dimensions: 19×203.2×1524mm

- Material: High Carbon Steel and Heat-Treated Boron Steel

- Color: Yellow (customizable upon request)

- Logo: SINOBL standard or your custom OEM logo

- Packaging: Plywood pallets with plastic wrap protection

- Delivery Time: 35 days after order confirmation

- Payment Terms: T/T, D/P, or as discussed

Usage Scenarios

You can rely on this blade across multiple demanding applications. Construction sites benefit from its robust cutting performance during site preparation and leveling work. Road maintenance crews trust its precision for creating smooth surfaces and proper drainage. Agricultural operations use it for land preparation and field maintenance. The blade excels in snow removal operations during winter months. Municipal departments depend on it for maintaining gravel roads and parking areas.

Product Features

Your equipment deserves the best components available. This fransgard grader blade undergoes a comprehensive eight-step manufacturing process including metal production, rolling, profiling, machining, heat treatment, shot blasting, painting, and careful packing. The heat-treated boron steel construction provides exceptional wear resistance. You get superior cutting efficiency that maximizes your equipment's productivity. The precision engineering ensures perfect compatibility with major grader models.

Quality Control

We maintain strict quality standards throughout production. Each blade passes through rigorous testing phases before leaving our facility. Our 55,944 square meter manufacturing plant follows international quality protocols. You receive products that meet or exceed OEM specifications. Independent research and development of materials ensures consistent quality. Every blade undergoes thorough inspection for dimensional accuracy and material integrity.

Why Choose Us?

SHANGHAI SINOBL PRECISION MACHINERY has served the industry since July 2011. You benefit from our extensive experience in producing OEM GET wear parts for bulldozers, wheel graders, loaders, and excavators. We maintain plenty of stock for fast delivery. Our OEM support includes custom logos and specifications. You get competitive pricing with FOB Qingdao terms.Our history as a nationwide and international OEM supplier attests to our dependability and credibility

FAQ

Q: How long does this grader blade usually last?

A: Although operating conditions affect lifespan, our heat-treated structure greatly increases service life in comparison to conventional blades.

Q: Is it possible to alter the measurements?

A: We can manufacture blades to your exact specifications and do provide OEM services.

Q: What does the packaging contain?

A: For safe transportation, each blade is packaged firmly on plywood pallets and covered with plastic wrap.

Q: Do you provide technical assistance?

A: Definitely. For correct installation and use, our engineering staff offers thorough technical support.

Q: Which forms of payment are accepted?

A: Upon mutual agreement, we accept T/T, D/P, and other payment types.

Contact Us

Ready to upgrade your equipment with our premium fransgard grader blade? Our staff is prepared to help with your unique needs. We offer comprehensive quotes and technical details based on your requirements.

For inquiries, pricing, and technical support, reach out to us at nancy@sunmach.com.cn. Our knowledgeable staff will get back to you right away with the data you require to decide on your fleet of equipment.