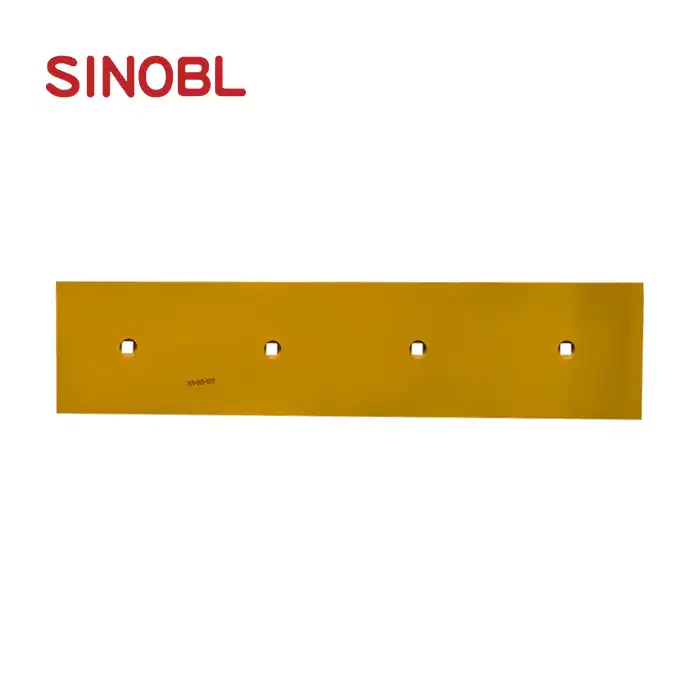

Type :GRADER BLADE

Unit Weight :60 KG

Dimensions 19*203.2*2133.6

Color

Yellow or as required by customer

Logo "SINOBL" logo, Customized OEM logo

Material :High Carbon Steel and Heat-Treated Boron Steel

Packaging :Normal plywood pallets

Wrapped with Plastic Wrap for added protection

Delivery Time :35 days after order confirmation

Price term FOB QINGDAO

Payment terms

T/T, D/P, Other payment as discussion

- Product Description

Curved Grader Blades - Premium Construction Equipment Parts

Our dedication to quality starts with the choice of materials for curved grader blades and lasts through the whole manufacturing process.These high-end blades, which are made by Shanghai Sinobl Precision Machinery Co., Ltd., combine precise engineering and advanced metallurgy to satisfy the demanding specifications of contemporary earthmoving machinery. Professional operators throughout the world rely on our T74772 model because it strikes the ideal mix between strength, resistance to wear, and cutting efficiency.

Product Introduction

These blades, which are made of heat-treated boron steel and high carbon steel, go through stringent quality control procedures. With dimensions of 19×203.2×2133.6mm and a weight of 60 kg, each blade is designed to work as well as possible with the majority of grader types. Superior cutting performance and longer service life will be experienced, maximizing the output of your equipment.

Product Specifications

| Specification | Details |

|---|---|

| Part Number | T74772 |

| Type | Grader Blade |

| Weight | 60 KG |

| Dimensions | 19×203.2×2133.6mm |

| Material | High Carbon Steel and Heat-Treated Boron Steel |

| Color | Yellow (customizable) |

| Logo | SINOBL or Custom OEM |

| Packaging | Plywood pallets with plastic wrap protection |

| Delivery Time | 35 days after confirmation |

| Payment Terms | T/T, D/P, or as discussed |

Usage Scenarios

These versatile blades excel in multiple applications:

- Road construction is ideal for establishing level, smooth surfaces on city streets and highways.

- Agricultural Land Preparation: Perfect for soil preparation and field levelin.

- Mining Operations: Dependable results under challenging mining conditions.

- Municipal Maintenance: Essential for maintaining existing roadways and infrastructure

- Snow Removal: Effective for winter road maintenance operations

Product Features

Superior Material Engineering

Heat-treated boron steel and high carbon steel are combined in our sophisticated metallurgy. This preserves the flexibility required for demanding applications while producing outstanding wear resistanc

Precision Manufacturing

Each blade undergoes a comprehensive eight-step process: metal production, rolling, profiling, machining, heat treatment, shot blasting, painting, and packing. This ensures consistent quality and performance.

Enhanced Durability

The heat treatment process significantly extends blade life. You'll experience reduced replacement frequency and lower operating costs.

Universal Compatibility

Designed to fit major grader models, these blades integrate seamlessly with your existing equipment fleet.

Quality Control

Our dedication to quality starts with the choice of materials and lasts through the whole manufacturing process. Consistent quality is ensured by independent material research and development. To ensure dimensional correctness, material qualities, and surface finish quality, every batch is put through a thorough testing process.

Strict quality requirements are maintained at our 55,944 square meter facility. We make sure every blade satisfies international standards prior to shipment by putting in place thorough inspection procedures at every level of manufacture.

Why Choose Us?

Established Excellence: Since our founding in 2011, we have established a solid reputation for providing both local and foreign markets with dependable wear parts.

Full Stock: Product and associated parts are always readily available because to our large stock.

OEM Experience: We are a reliable supplier to leading equipment manufacturers across the globe.

Fast Delivery: Order fulfillment is made possible by a strategic location and effective logistics.

Custom Solutions: We can meet certain needs, such as OEM branding and custom colors.

All-inclusive Support: Our technical staff offers post-purchase assistance and application advice.

FAQ

Q: How long do these blades usually last?

A: Operating conditions and application affect lifespan. When compared to ordinary blades, our heat-treated structure usually results in a 30–50% longer service life.

Q: Is it possible to alter the measurements for particular pieces of equipment?

A: For unique uses, we do provide custom manufacturing. For consultation, get in touch with our technical staff.

Q: What's your minimum order quantity?

A: We accommodate various order sizes. Larger quantities receive preferential pricing.

Q: How do you ensure quality during shipping?

A: All product are packaged in plywood pallets with protective plastic wrapping to prevent damage during transit.

Q: Do you provide installation guidance?

A: Yes, our technical team offers installation support and operational recommendations.

Contact Us

Are you prepared to use high-quality blades to improve your grading operations? Our knowledgeable staff is available to help with order processing, technical inquiries, and product selection.

Email: nancy@sunmach.com.cn

Get in touch with us right now to go over your unique needs and find out how our curved grader blades can boost the efficiency and performance of your machinery.