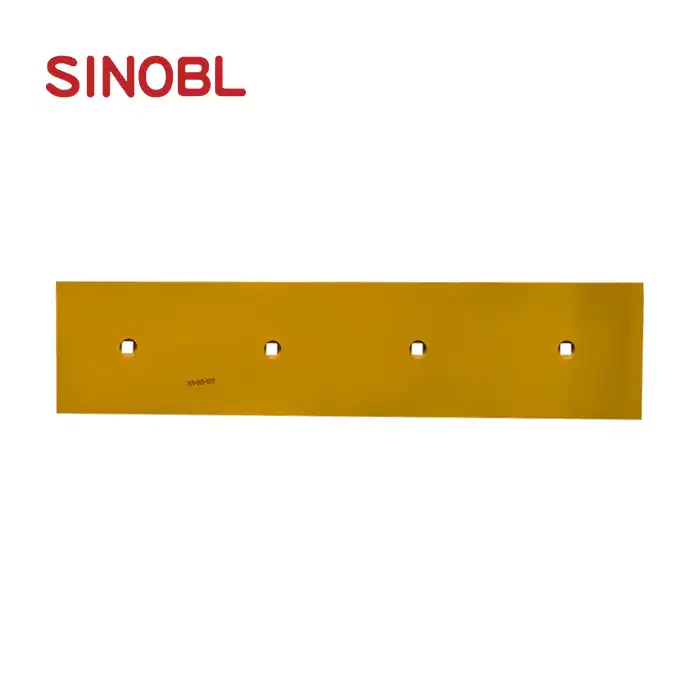

Type :END BIT

Unit Weight : 19.8 KG

Dimensions30*253*400

Color

Yellow or as required by customer

Logo "SINOBL" logo, Customized OEM logo

Material :High Carbon Steel and Heat-Treated Boron Steel

Packaging :Normal plywood pallets

Wrapped with Plastic Wrap for added protection

Delivery Time :30 days after order confirmation

Price term FOB QINGDAO

Payment terms

T/T, D/P, Other payment as discussion

- Product Description

High-Performance Cutting Edges and End Bits for Heavy Machinery

When you need reliable ground engaging tools for your heavy equipment, our cutting edges and end bits deliver unmatched performance and durability. Shanghai Sinobl Precision Machinery Co., Ltd brings you premium wear parts designed specifically for bulldozers, wheel graders, loaders, and excavators. Our product feature superior materials and precision engineering to maximize your equipment's productivity while minimizing operational costs.

Product Introduction

Our flagship Part No. 6J0896 end bit represents years of engineering excellence.You receive a sturdy 19.8 KG part that can survive the most demanding operating circumstances. Every component is put through a thorough quality testing process to guarantee reliable performance in demanding applications.

Product Specifications

| Specification | Details |

|---|---|

| Part Number | 6J0896 |

| Type | End Bit |

| Weight | 19.8 KG |

| Dimensions | 30×253×400mm |

| Material | High Carbon Steel and Heat-Treated Boron Steel |

| Color | Yellow (custom colors available) |

| Logo | SINOBL standard or customized OEM |

| Packaging | Plywood pallets with plastic wrap protection |

| Delivery Time | 30 days after order confirmation |

| Payment Terms | T/T, D/P, or negotiable |

Usage Scenarios

You'll find our wear parts excel in various demanding environments:

- Construction Sites: Perfect for excavation and grading operations

- Mining Operations: Handles abrasive materials with exceptional durability

- Road Construction: Maintains precision during paving and surface preparation

- Agricultural Projects: Supports land clearing and terrain modification

- Demolition Work: Withstands high-impact applications

Product Features

Superior Material Composition

Our product use high carbon steel combined with heat-treated boron steel. This combination provides exceptional hardness while maintaining flexibility under stress.

Precision Manufacturing

Each component follows our comprehensive 8-step manufacturing process:

- Metal production

- Rolling

- Profiling

- Machining

- Heat treatment

- Shot blasting

- Painting

- Packing

Custom Solutions

You can customize colors, logos, and specifications to match your exact requirements. We support OEM partnerships with flexible design options.

Quality Control

We maintain strict quality standards throughout production of cutting edges and end bits.Every piece undergoes multiple inspection points to ensure dimensional accuracy and material integrity. Our heat treatment processes follow industry best practices for optimal hardness and wear resistance.Temperature monitoring and material testing guarantee consistent quality across all batches. You receive products that meet or exceed original equipment specifications.

Why Choose Us?

Established Expertise

Since 2011, we've specialized in manufacturing OEM GET wear parts. Our 55,944 sqm facility demonstrates our commitment to large-scale production capabilities.

Comprehensive Service

- Independent research and development of materials

- Domestic and overseas OEM supplier relationships

- Extensive inventory for immediate availability

- Complete certification documentation

Reliable Delivery

Your investment is safeguarded by prompt delivery and safe packaging. Project planning is predictable because to our normal 30-day production schedule.

Cost-Effective Solutions

Middleman costs are eliminated with direct manufacturer pricing. You receive flexible payment arrangements along with excellent quality at competitive prices.

FAQ

Q: What makes your cutting edges and end bits different from competitors?

A: Our special blend of heat-treated boron steel and high carbon steel offers exceptional durability. Additionally, constant quality is guaranteed by our extensive manufacturing procedure.

Q: Is it possible to modify items to fit particular models of equipment?

A: To meet your precise requirements, we provide complete OEM customization, including changes to measurements, materials, colors, and logos.

Q: What is the minimum order quantity that you require?

A: To support both large-scale operations and smaller projects, we retain variable order amounts.

Q: How do you guarantee the quality of your products?

A: Prior to delivery, each product goes through a number of quality control checkpoints, material testing, and dimensional verification.

Q: What choices are there for shipping?

A: We offer FOB Qingdao terms with secure plywood pallet packaging and plastic wrap protection for safe transport.

Contact Us

Ready to upgrade your equipment with premium cutting edges and end bits? Our technical team stands ready to help you select the perfect components for your specific applications.

For detailed quotations, technical specifications, or custom solutions, reach out to our expert team today.

Email: nancy@sunmach.com.cn

Let us help you maximize your equipment's performance with our proven wear parts solutions. Your productivity matters, and we're here to support your success