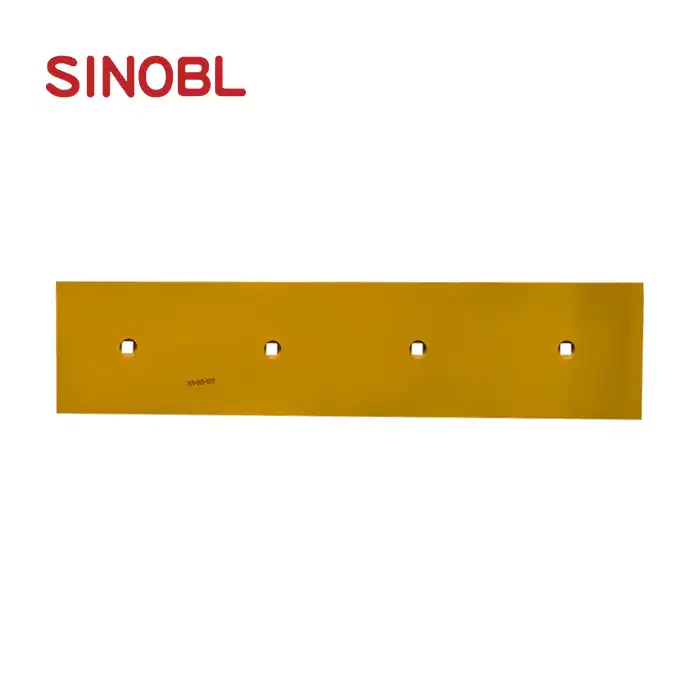

Type :END BIT

Unit Weight : 97.1 KG

Dimensions45*490*730

Color

Yellow or as required by customer

Logo "SINOBL" logo, Customized OEM logo

Material :High Carbon Steel and Heat-Treated Boron Steel

Packaging :Normal plywood pallets

Wrapped with Plastic Wrap for added protection

Delivery Time :30 days after order confirmation

Price term FOB QINGDAO

Payment terms

T/T, D/P, Other payment as discussion

- Product Description

Bulldozer End Bit 8E4199 - Premium Heavy Machinery Wear Parts

When you need reliable ground engaging tools for your heavy machinery operations, the bulldozer end bit 8E4199 stands out as your premier choice. This meticulously designed worn component performs exceptionally well in the most taxing mining and construction settings. This end bit, which is made by SHANGHAI SINOBL PRECISION MACHINERY CO., LTD, combines high-quality materials with cutting-edge manufacturing techniques to guarantee your equipment runs as efficiently as possible. Because of our dedication to quality, you will receive a product that is both highly productive and resistant to harsh environments.

Product Specifications

| Specification | Details |

|---|---|

| Part Number | 8E4199 |

| Type | End Bit |

| Unit Weight | 97.1 KG |

| Dimensions | 45×490×730 mm |

| Material | High Carbon Steel and Heat-Treated Boron Steel |

| Color | Yellow (customizable) |

| Logo | SINOBL (OEM available) |

| Packaging | Plywood pallets with plastic wrap protection |

| Delivery Time | 30 days after confirmation |

| Payment Terms | T/T, D/P, or negotiable |

Usage Scenarios

Your heavy machinery faces tough challenges daily. This end bit excels in:

- Construction Projects: Road building, site preparation, and foundation work

- Mining Operations: Material handling and ground breaking applications

- Agricultural Work: Land clearing and terrain modification

- Infrastructure Development: Highway construction and utility installations

- Demolition Projects: Dismantling buildings and managing trash

Consistent performance across a range of soil conditions and operational demands is guaranteed by the sturdy design.

Product Features

Superior Material Composition: We offer outstanding durability and wear resistance thanks to our high carbon steel and heat-treated boron steel construction.

Precision Engineering: Consistent quality is guaranteed by sophisticated manufacturing techniques such as metal fabrication, rolling, profiling, machining, heat treatment, shot blasting, and painting.

Ideal Weight Distribution: This component, weighing 97.1 KG, provides the ideal ratio of robustness to operational effectiveness.

Customization Options: For brand coherence, we can attach your OEM logo and meet your precise color specifications.

Enhanced Protection: Your investment will arrive in ideal shape thanks to expert packaging using plywood pallets and plastic wrap.

Quality Control

Every bulldozer end bit 8E4199 undergoes rigorous quality testing throughout our manufacturing process. From the selection of raw materials to the final inspection, our 55,944 square meter facility upholds stringent quality requirements. We carry out thorough testing for performance requirements, material integrity, and dimensional accuracy. This methodical process guarantees that the product you receive satisfies the highest industry requirements and operates dependably in challenging situations.

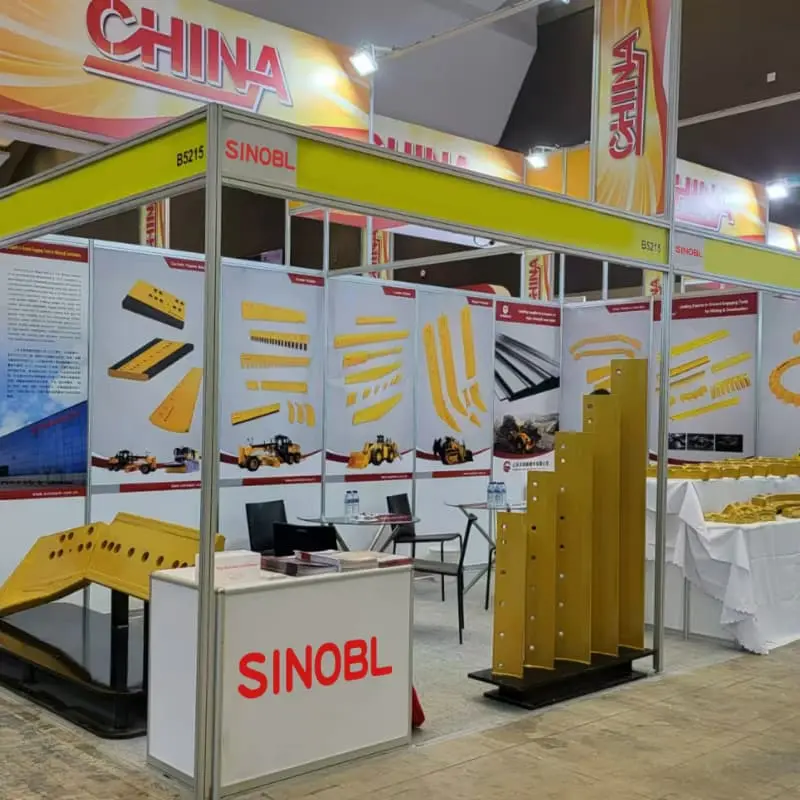

Why Choose Us?

Established Expertise: We have been specializing in OEM GET wear parts for loaders, excavators, wheel graders, and bulldozers since 2011.

Independent R&D: We guarantee ongoing product innovation and improvement with our in-house R&D skills.

Comprehensive Stock: If you have a lot of inventory, your urgent project demands will be delivered more quickly.

OEM Partnership: Both domestic and foreign original equipment manufacturers rely on us as a reliable provider.

Complete paperwork: Your procurement and compliance obligations are supported by all required certificates and paperwork.

Quick Delivery: We can ship quickly to locations around the world thanks to our optimized procedures and advantageous location.

Certifications

Comprehensive quality management procedures are maintained at our manufacturing facilities. As evidence of our dedication to quality, safety, and environmental standards, we possess pertinent industry certifications. These certifications demonstrate our commitment to offering you goods that satisfy legal and international standards.

FAQ

Q: Why is this end bit appropriate for demanding applications?

A: Our unique production method, along with the mix of heat-treated boron steel and high carbon steel, produces remarkable endurance and wear resistance.

Q: Is it possible to alter the branding and color?

A: In order to preserve brand uniformity throughout your fleet of equipment, we can add your OEM logo and enable color personalization.

Q: What's included in your quality assurance process?

A: Every product undergoes comprehensive testing including dimensional verification, material analysis, and performance validation.

Q: How do you ensure safe delivery?

A: We use professional plywood pallet packaging with protective plastic wrap, ensuring your order arrives in perfect condition.

Q: What payment options do you accept?

A: We accept T/T, D/P, and other payment methods based on mutual agreement.

Contact Us

Are you prepared to improve the performance of your heavy machinery? Our knowledgeable staff is here to assist you in locating the ideal solution for your unique requirements. We are dedicated to helping you succeed, whether you require pricing details, technical specs, or unique solutions.

Email:nancy@sunmach.com.cn

Connect with us today to discuss how our premium bulldozer end bit 8E4199 can improve your operational efficiency and reduce downtime. We look forward to becoming your trusted partner in heavy machinery wear parts.