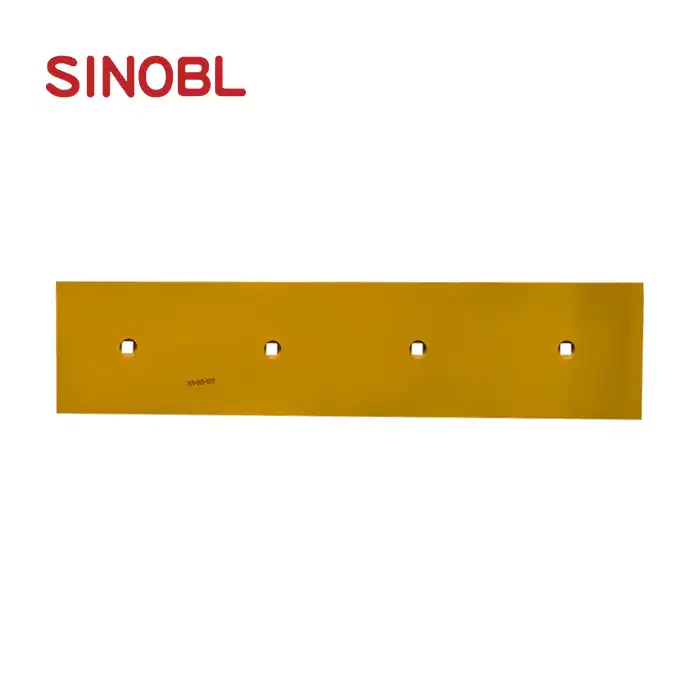

Type :CUTTING EDGE

Unit Weight : 25.9

Dimensions25*254*545

Color

Yellow or as required by customer

Logo "SINOBL" logo, Customized OEM logo

Material :High Carbon Steel and Heat-Treated Boron Steel

Packaging :Normal plywood pallets

Wrapped with Plastic Wrap for added protection

Delivery Time :34 days after order confirmation

Price term FOB QINGDAO

Payment terms

T/T, D/P, Other payment as discussion

- Product Description

GPS Bulldozer Blade - High-Performance Cutting Edge Solutions

Finding a dependable gps bulldozer blade cutting edge requires tools that operate consistently under trying circumstances. Our Part No. 417-70-B3160 cutting edge is specifically engineered for precision earthmoving operations. This product component combines advanced materials with proven manufacturing processes to ensure your equipment operates at peak efficiency.Our cutting edge is designed to withstand the toughest jobsite conditions while maintaining sharp cutting performance. You'll experience superior material penetration and extended service life that keeps your projects moving forward without costly downtime.

Product Specifications

| Specification | Details |

|---|---|

| Part Number | 417-70-B3160 |

| Type | Cutting Edge |

| Weight | 25.9 kg |

| Dimensions | 25×254×545 mm |

| Material | High Carbon Steel and Heat-Treated Boron Steel |

| Color | Yellow (customizable) |

| Logo | SINOBL or OEM customization |

| Packaging | Plywood pallets with plastic wrap protection |

| Delivery Time | 34 days after order confirmation |

| Payment Terms | T/T, D/P, or negotiable |

Usage Scenarios

Your gps bulldozer blade cutting edge performs exceptionally across multiple applications:

- Heavy Construction Sites: Road building, site preparation, and foundation work.

- Mining Operations: Material handling and ground preparation in quarries.

- Agricultural Projects: Preparing fields and removing land.

- Infrastructure Development: Highway construction and utility installations.

- Demolition Work: Debris management and site cleanup.

Each scenario demands reliable performance, and our cutting edge delivers the durability you need for successful project completion.

Product Features

Superior Material Composition: Our cutting edge uses high carbon steel combined with heat-treated boron steel for maximum wear resistance and impact strength.

Precision Manufacturing: Every component undergoes our complete manufacturing process: metal production, rolling, profiling, machining, heat treatment, shot blasting, painting, and careful packaging.

Extended Service Life: The advanced steel composition and heat treatment process significantly reduce replacement frequency, lowering your operational costs.

Custom Solutions Available: We offer OEM customization including logo placement and color specifications to match your equipment requirements.

Quality Control

Agricultural Projects: Preparing fields and removing land lities.Everything we do is driven by quality. Our 55,944-square-meter manufacturing facility is furnished with sophisticated production equipment and stringent quality control procedures.

Agricultural Projects: Preparing fields and removing land lities.During the production process, every cutting edge is put through a thorough testing procedure. We maintain complete certificates and documentation for material traceability. Our heat treatment process ensures consistent hardness and wear characteristics across every batch.

Agricultural Projects: Preparing fields and removing land lities.Our ability to conduct independent research and development enables us to consistently enhance our manufacturing procedures and materials. This dedication to innovation guarantees that every product has state-of-the-art technology.

Why Choose Us?

Established Expertise: Since 2011, we've specialized in GET wear parts for bulldozers, wheel graders, loaders, and excavators. This focused experience translates into superior products for your equipment.

Comprehensive Inventory: Our extensive stock ensures quick availability when you need replacement parts. No more waiting weeks for critical components.

Fast Delivery: With plenty of stock and efficient logistics, we deliver your gps bulldozer blade components when you need them.

Certifications

Our facility maintains comprehensive quality certifications and material documentation. All products meet industry standards for construction equipment wear parts. Complete traceability documentation accompanies every shipment.

FAQ

Q: What makes your cutting edge different from competitors?

A: Compared to conventional steel substitutes, our blend of high carbon steel and heat-treated boron steel offers better wear resistance and a longer service life.

Q: Is it possible to modify the cutting edge to fit our particular equipment?

A: In accordance with your equipment standards, we do provide OEM customization, including changes to colors, logos, and measurements.

Q: How long does delivery typically take?

A: Standard delivery time is 34 days after order confirmation, though we often have stock available for faster shipment.

Q: What payment options do you accept?

A: We accept T/T, D/P, and other payment terms through discussion to accommodate your business needs.

Q: Do you provide technical support after purchase?

A: Absolutely. Our technical team provides ongoing support to ensure optimal performance of your wear parts.

Contact Us

Agricultural Projects: Preparing fields and removing land liabilities. Are you prepared to use our state-of-the-art, high-performance solutions like gps bulldozer blade to improve your equipment? Our staff is prepared to go over your particular needs and offer thorough quotes.

For inquiries about our complete range of wear parts or to place an order, reach out to us at nancy@sunmach.com.cn. We'll respond promptly with the information you need to keep your projects moving forward efficiently.

_1761269482712.webp)