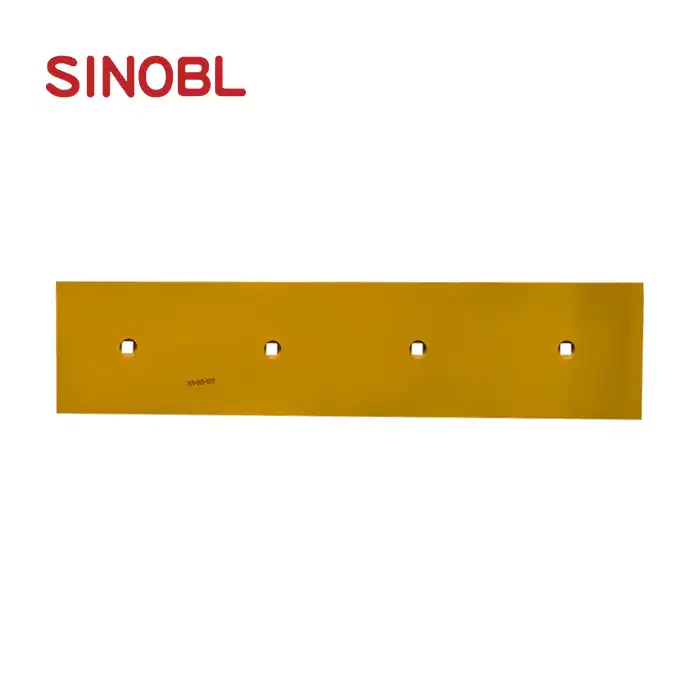

Type :CUTTING EDGE

Unit Weight : 43.1 KG

Dimensions:20*254*1157.6

Color

Yellow or as required by customer

Logo "SINOBL" logo, Customized OEM logo

Material :High Carbon Steel and Heat-Treated Boron Steel

Packaging :Normal plywood pallets

Wrapped with Plastic Wrap for added protection

Delivery Time :25 days after order confirmation

Price term FOB QINGDAO

Payment terms

T/T, D/P, Other payment as discussion

- Product Description

Shanghai SINOBL Precision Machinery: Your Trusted Dozer Push Blade 154-70-11314 Manufacturer

Shanghai SINOBL Precision Machinery Co., Ltd excels in manufacturing premium dozer push blade 154-70-11314 components. Our advanced engineering, superior materials, and customization options make us the go-to supplier for construction firms worldwide seeking durable, efficient dozer push blades.

Product Introduction: Dozer Push Blade 154-70-11314

Our product is engineered to meet the demanding needs of global construction and earthmoving operations. Designed for optimal performance in challenging terrains, this blade offers exceptional durability, precision, and cost-effectiveness.

Product Parameters

| Specification | Detail |

|---|---|

| Model Number | 154-70-11314 |

| Material | High-grade AR450 steel |

| Hardness | ≥55 HRC |

| Width | Customizable |

| Height | Customizable |

| Thickness | Optimized for durability |

| Coating | Rust-proof epoxy finish |

| Compatibility | Universal fit for major dozer brands |

Usage Scenarios

Our product excels in various applications:

- Heavy construction sites

- Mining operations

- Land clearing and grading

- Road construction

- Forestry and land management

Whether you're tackling rocky terrain in North America or dealing with abrasive soils in the Middle East, our product is built to perform.

Product Features

- Superior Wear Resistance: AR450 steel construction combats extreme wear and tear.

- Precision Engineering: ISO 286-2 tolerances ensure perfect fitment across dozer models.

- Enhanced Edge Retention: Hardened cutting edges maintain sharpness for extended periods.

- Corrosion Protection: Advanced epoxy coating prevents rust in diverse climates.

- Modular Design: Easily replaceable components reduce downtime and maintenance costs.

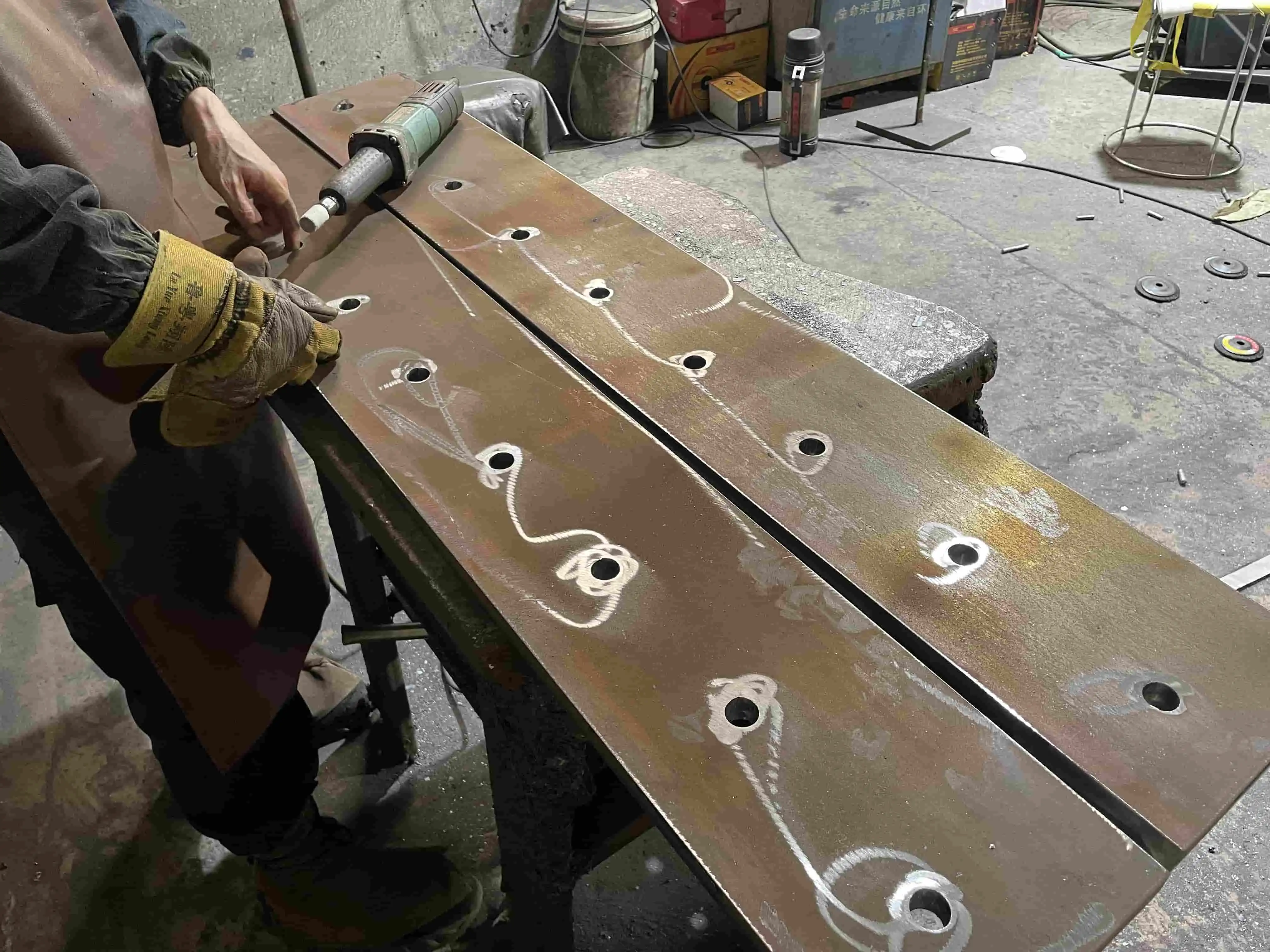

Quality Control

Every dozer push blade 154-70-11314 undergoes rigorous quality checks:

- Material composition analysis

- Hardness testing

- Dimensional accuracy verification

- Weld integrity inspection

- Coating thickness measurement

Why Choose Us?

- Industry-leading durability reduces frequent replacements

- Customization options to meet specific project requirements

- Fast lead times (<4 weeks for urgent orders)

- Comprehensive warranty and after-sales support

- Proven track record with major construction firms globally

OEM & ODM Services

Leverage our expertise for your branded products:

- Custom design and engineering support

- Prototype development and testing

- Full-scale production capabilities

- Strict quality control and documentation

- Flexible order quantities

Certifications

- ISO 9001:2015 Quality Management System

- CE Marking for European markets

- OSHA compliance for North American safety standards

- AS/NZS 4024 certification for Australian/New Zealand markets

Packaging and Delivery

- Robust packaging for international shipping

- Wooden crates or metal frames for added protection

- Express air freight available for urgent orders

- Bulk sea freight options for large quantities

FAQ

Q: What's the typical lifespan of your product?

A: Under normal operating conditions, our blades last 30-50% longer than standard alternatives.

Q: Can you provide custom sizes for specific dozer models?

A: Absolutely! We offer tailored solutions to fit any dozer make and model.

Q: Do you offer volume discounts for large orders?

A: Yes, we provide competitive pricing for bulk purchases. Contact us for a custom quote.

Contact Us

Ready to upgrade your dozer fleet with our high-performance dozer push blade 154-70-11314? Contact our sales team today:

Email: nancy@sunmach.com.cn

Experience the SINOBL difference – where quality meets innovation in dozer push blade technology.