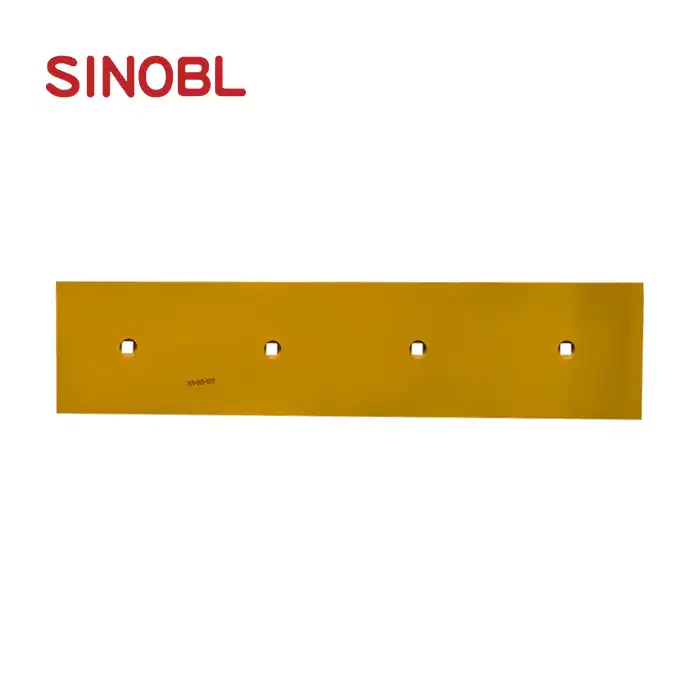

Type :END BIT

Unit Weight : 20 KG

Dimensions

25*254*465

Color

Yellow or as required by customer

Logo "SINOBL" logo, Customized OEM logo

Material :High Carbon Steel and Heat-Treated Boron Steel

Packaging :Normal plywood pallets

Wrapped with Plastic Wrap for added protection

Delivery Time :26 days after order confirmation

Price term FOB QINGDAO

Payment terms

T/T, D/P, Other payment as discussion

- Product Description

Dozer Cutting Edges And End Bits 9W8874: Professional Grade Heavy Equipment Parts

When your bulldozer demands reliable performance on the toughest job sites, Dozer Cutting Edges And End Bits 9W8874 delivers the durability you need. This high-quality end bit weighs 20 KG and measures 25254465mm, making it perfect for heavy-duty earthmoving operations. Manufactured by Shanghai SINOBL Precision Machinery Co., Ltd, this replacement part ensures your equipment maintains peak cutting performance across challenging terrain.

Superior Construction for Maximum Durability

Your bulldozer faces extreme conditions daily. That's why our 9W8874 end bit features high carbon steel construction with heat-treated boron steel reinforcement. This advanced material combination provides exceptional wear resistance and extends service life significantly.

The precision manufacturing process ensures perfect fitment every time. You'll experience seamless installation without compatibility issues. The yellow finish provides excellent visibility during operation while protecting against corrosion.

Technical Specifications That Meet Industry Standards

Professional contractors choose our end bits for their consistent performance. Here are the key specifications:

- Part Number: 9W8874

- Type: End Bit

- Weight: 20 KG

- Dimensions: 25254465mm

- Material: High Carbon Steel with Heat-Treated Boron Steel

- Finish: Yellow (custom colors available)

- Logo: SINOBL standard or custom OEM branding

These specifications ensure compatibility with major bulldozer models. Your equipment will maintain optimal cutting angles and ground engagement throughout the part's lifecycle.

Quality Manufacturing Process

Our manufacturing facility employs advanced heat treatment processes. This creates the perfect balance between hardness and toughness. You get maximum cutting efficiency without brittleness that causes premature failure.

Each product undergoes rigorous quality testing. We verify dimensional accuracy, material composition, and surface finish before shipping. This attention to detail guarantees consistent performance across every unit.

Packaging and Delivery Excellence

Protection during shipping is crucial for maintaining part integrity. We use robust plywood pallets with plastic wrap protection. This packaging system prevents damage during transport and storage.

Delivery typically takes 26 days after order confirmation. We ship FOB Qingdao with flexible payment terms including T/T and D/P options. Our logistics team coordinates with freight forwarders to ensure timely arrival at your location.

Applications Across Multiple Industries

Construction, mining, and agricultural operations rely on these end bits daily. Whether you're clearing land, moving aggregate, or maintaining roadways, our parts deliver consistent results.

The product excels in abrasive soil conditions. Rocky terrain and dense clay present no challenges for this robust component. Your productivity remains high while maintenance intervals extend significantly.

Cost-Effective Solution for Fleet Operators

Fleet managers appreciate our competitive pricing structure. Bulk ordering options provide additional savings for large operations. The extended service life reduces total cost of ownership compared to standard replacement parts.

Our technical support team assists with application questions and installation guidance. You receive comprehensive support throughout the product lifecycle.

Why Choose SINOBL Precision Machinery?

Shanghai SINOBL Precision Machinery Co., Ltd brings decades of experience to heavy equipment parts manufacturing. Our engineering team understands the demanding requirements of modern construction equipment.

We maintain strict quality control standards throughout production. ISO certification ensures consistent manufacturing processes. Your Dozer Cutting Edges And End Bits 9W8874 meets or exceeds original equipment specifications.

Ready to upgrade your bulldozer's performance? Contact our sales team for pricing and availability information.

Frequently Asked Questions

Q: What bulldozer models are compatible with part number 9W8874?

A: This end bit fits multiple Caterpillar bulldozer models. Contact our technical team with your specific machine serial number for compatibility confirmation.

Q: How does heat-treated boron steel improve performance?

A: Heat treatment increases hardness while maintaining toughness. This prevents premature wear while resisting impact damage from rocks and debris.

Q: Can you customize the logo or color?

A: Yes, we offer custom OEM branding and alternative colors based on your requirements. Minimum order quantities may apply for custom options.

Q: What's included with the 26-day delivery timeframe?

A: This includes manufacturing time and preparation for shipment. Transit time depends on your location and chosen shipping method.

Q: Do you offer technical support for installation?

A: Our engineering team provides installation guidance and technical support. We also supply detailed drawings and specifications upon request.

Contact Us

For additional questions about Dozer Cutting Edges And End Bits 9W8874 or to place your order, reach out to nancy@sunmach.com.cn today.