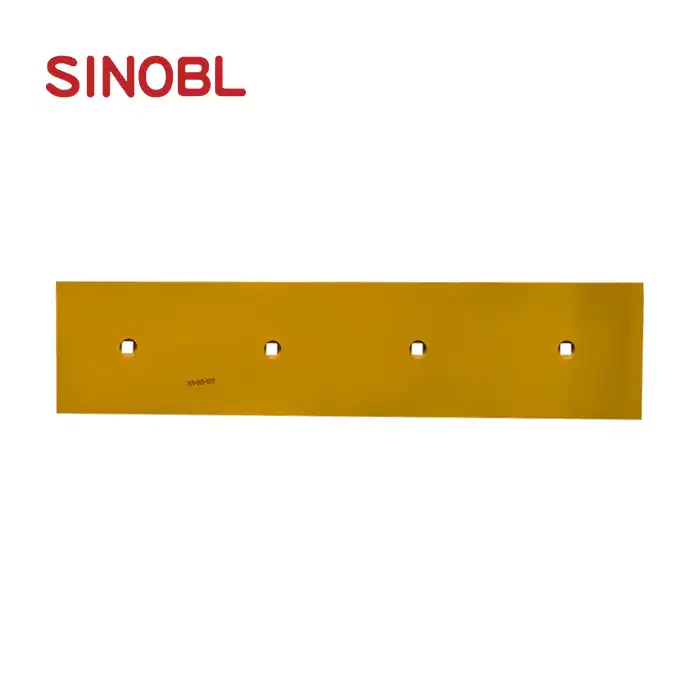

Type :CUTTING EDGE

Unit Weight :56.8

Dimensions20*254*1525

Color

Yellow or as required by customer

Logo "SINOBL" logo, Customized OEM logo

Material :High Carbon Steel and Heat-Treated Boron Steel

Packaging :Normal plywood pallets

Wrapped with Plastic Wrap for added protection

Delivery Time :34 days after order confirmation

Price term FOB QINGDAO

Payment terms

T/T, D/P, Other payment as discussion

- Product Description

Dozer Brush Blade - Heavy-Duty Cutting Edge Solutions

When you need reliable ground engagement tools for your bulldozer operations, our dozer brush blade delivers exceptional performance. This cutting edge attachment transforms your equipment into a powerful land clearing machine. To tackle the most difficult terrain, our product Part No. 9W8620 blends premium materials with precise engineering. Whether you are prepping construction sites, moving waste, or clearing undergrowth, you will be more productive. Your dozer's sturdy build guarantees optimal performance even under the most taxing circumstances.

Product Specifications

| Specification | Details |

|---|---|

| Part Number | 9W8620 |

| Type | Cutting Edge |

| Weight | 56.8 kg |

| Dimensions | 20×254×1525 mm |

| Material | High Carbon Steel and Heat-Treated Boron Steel |

| Color | Yellow (customizable) |

| Logo | SINOBL standard or OEM customization |

| Packaging | Plywood pallets with plastic wrap protection |

| Delivery Time | 34 days after confirmation |

| Payment Terms | T/T, D/P, flexible options available |

Usage Scenarios

Your bulldozer faces various challenges daily. This cutting edge excels in heavy construction sites where you need to move large amounts of material. Mining operations benefit from its durability when handling abrasive materials. Forestry work becomes more efficient as you clear fallen trees and dense vegetation. Projects involving the construction of roads need dependable equipment that can withstand stress. Equipment for agricultural land preparation must be able to easily handle rocks and roots.

Product Features

Superior Material Composition: Excellent wear resistance is provided by the high carbon steel structure. Heat-treated boron steel increases service life and durability.

Precision Manufacturing: We use an eight-step process that involves rolling, profiling, machining, heat treatment, shot blasting, painting, and meticulous packing in addition to metal fabrication.

Extended Operational Lifespan: Lowers your total expenses and the frequency of replacements. You will be working more and doing less maintenance.

Customization Options: To satisfy your fleet branding needs, select your favorite color and logo.

Increased Productivity: The ground engagement capabilities of your bulldozer are maximized by an optimized design.

Quality Control

Every dozer brush blade cutting edge undergoes rigorous testing throughout our manufacturing process.We monitor material composition to ensure consistent quality standards. Strict guidelines are followed throughout heat treatment processes to achieve the best possible hardness and durability. The ideal surface finish for paint adherence is produced by shot blasting. To ensure that you only receive the greatest products, our quality team examines every item before packaging.

Why Choose Us?

Shanghai Sinobl Precision Machinery brings over 12 years of experience to your projects. Our 55,944 square meter facility produces OEM GET wear parts for major equipment manufacturers. You benefit from our independent research and development capabilities that keep us ahead of industry trends. We maintain substantial inventory levels for faster delivery times. Our domestic and overseas OEM partnerships demonstrate the trust manufacturers place in our products.

Fast Delivery: 34-day delivery schedule keeps your equipment running.

Flexible Payment: Multiple payment options accommodate your business needs.

OEM Support: Custom manufacturing capabilities for specialized requirements.

Complete Certificates: All necessary documentation for international shipping and compliance.

Certifications

Our manufacturing processes meet international quality standards. We maintain proper documentation for all materials and procedures. Export certifications ensure smooth customs clearance for international customers.

FAQ

Q: How long will this dozer brush blade last in normal operations?

A: Although operating conditions affect service life, our heat-treated boron steel construction usually results in a 30–50% longer lifespan than normal choices.

Q: Is it possible to alter the measurements for particular equipment models?

A: We can manufacture cutting edges to your exact requirements and do provide OEM services.

Q: What's included with each order?

A: Each cutting edge comes with protective packaging, necessary hardware, and complete documentation.

Q: Do you offer bulk pricing for fleet operators?

A: Absolutely. Contact us for volume discounts on multiple units.

Q: Is installation hardware included?

A: Standard mounting hardware is included. Special requirements can be accommodated upon request.

Contact Us

Are you prepared to improve the performance of your bulldozer with dozer brush blade?Our staff is prepared to assist you in choosing the best state-of-the-art solution for your unique requirements. We are here to help your operations whether you require technical specs, price details, or bids for custom manufacturing.

Email: nancy@sunmach.com.cn

Get in touch today and discover why contractors worldwide trust our cutting edge solutions for their most demanding projects.

_1761700674534.webp)