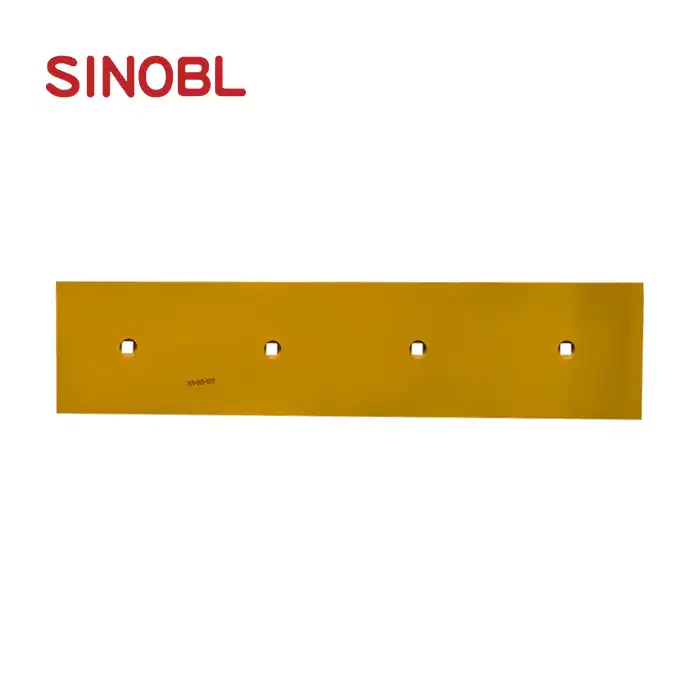

Type :CUTTING EDGE

Unit Weight :43.9KG

Dimensions:25*280*910

Color:Yellow or as required by customer

Logo "SINOBL" logo, Customized OEM logo

Material :High Carbon Steel and Heat-Treated Boron Steel

Packaging :Normal plywood pallets Wrapped with Plastic Wrap for added protection

Delivery Time :25 days after order confirmation

Price term FOB QINGDAO

Payment terms:T/T, D/P, Other payment as discussion

- Product Description

Shanghai SINOBL Precision Machinery Co., Ltd: Your Trusted Dozer Edge-Cutting 4721467 Manufacturer & Supplier

As Shanghai SINOBL Precision Machinery Co., Ltd, our core advantage lies in supplying top-tier Dozer Edge-Cutting 4721467 solutions for harsh construction and mining operation scenarios. Our cutting edges are professionally developed, boasting excellent durability, operational performance, and cost-effectiveness, making us a trusted choice for procurement managers and fleet directors worldwide.

Product Introduction: Dozer Edge-Cutting 4721467

The Dozer Edge - Cutting 417 - 815 - 1220 is designed to enhance dozer productivity and reduce downtime. It combines high-carbon steel and heat-treated boron steel to achieve a balance of hardness and impact resistance. The high-carbon steel allows it to cut through tough materials effectively, while the heat-treated boron steel provides increased strength, reducing the risk of fractures and deformation. This material composition ensures strong wear resistance, enabling the edge to retain its sharpness and structural integrity over time. Suitable for rocky ground, thick mud, and abrasive soils, this cutting edge delivers reliable performance in demanding conditions, helping maintain your dozer's operational efficiency and extend service intervals.

Product Parameters:

|

Specification

|

Details

|

|

Part No.

|

4721467

|

|

Type

|

CUTTING EDGE

|

|

Unit Weight

|

43.9KG

|

|

Dimensions

|

25*280*910

|

|

Color

|

Yellow (Customizable)

|

|

Logo

|

“SINOBL" logo (OEM available)

|

|

Material

|

High Carbon Steel and Heat-Treated Boron Steel

|

Usage Scenarios

The Dozer Edge-Cutting 4721467 is ideal for:

- Large-Scale Earthmoving Projects: From shaping landscapes for new developments to building dam embankments, this edge delivers consistent performance in pushing and spreading large volumes of soil and aggregate.

- Mining and Quarrying Operations: Built to withstand the extreme abrasion of minerals and the sudden impacts of buried rock, it ensures reliable productivity in the most challenging extraction environments.

- Road Construction and Site Preparation: It effectively handles tasks from clearing topsoil and vegetation to fine-grading sub-base materials, providing the precision and durability needed for creating stable foundations.

- Land Clearing and Grading: Whether clearing wooded areas of roots and debris or performing final grading for construction pads, this edge maintains its integrity to complete the task efficiently.

Whether you're managing a fleet of dozers for large-scale construction projects or overseeing mining operations, our cutting edge is designed to meet your demanding requirements.

Product Features

-

Superior Wear Resistance: Designed to withstand highly abrasive working conditions, it effectively resists wear and significantly extends equipment service life by reducing the frequency of replacements.

- Excellent Comprehensive Strength: The heat treatment process enhances both hardness and impact resistance, enabling it to withstand sudden loads in harsh working environments.

- Precision Manufacturing Technology: Precision engineering ensures compatibility with a wide range of equipment models, enabling quick and easy installation to minimize downtime.

- Outstanding Cost Efficiency: Its long-lasting durability and extended replacement cycles help reduce long-term costs for parts procurement and maintenance.

- Broad Equipment Compatibility: Suitable for multiple brands and models of bulldozers, providing a versatile solution for various users and operational scenarios.

Quality Control

At SINOBL, our commitment to quality is integral to every stage of the manufacturing process. We maintain excellence through:

- Comprehensive Material Testing: All raw materials undergo stringent verification to ensure they meet precise specifications and performance standards.

- Precision Machining & Technology: We utilize advanced, computer-controlled equipment to guarantee consistent dimensional accuracy and superior finish in every component.

- Multi-Stage Inspection Protocol: Each product is scrutinized at critical production points—from initial processing to final assembly—ensuring any potential deviation is identified and corrected promptly.

- Certified Standards Compliance: Our processes and final products rigorously adhere to internationally recognized quality management systems, providing reliable and verifiable quality assurance to our customers.

Why Choose Us?

● Proven Expertise: With years of dedicated experience in the field, we possess the practical knowledge to effectively address your specific challenges and requirements.

● Tailored Solutions: We go beyond standard offerings by providing customizable options designed to perfectly align with your unique project needs.

● Optimal Value: We are committed to delivering high-quality products at competitive prices, ensuring you receive the best balance of cost and performance.

● Guaranteed Timeliness: Our reliable logistics and operational processes are fine-tuned to ensure your orders are delivered as scheduled, supporting the seamless flow of your operations.

● Responsive Support: Our dedicated support team provides prompt and helpful assistance at every stage, ensuring a smooth and satisfactory experience.

OEM & ODM Services

We offer flexible OEM and ODM services to meet your unique specifications:

· Customizable dimensions and designs

· Branding options with your logo

· Material selection to suit your application

· Tailored packaging solutions

Certifications

Our commitment to quality is backed by international certifications:

· ISO 9001:2015 Quality Management System

· CE Certification

· RoHS Compliance

Packaging and Delivery

· Secure Packaging: Normal plywood pallets wrapped with plastic for added protection

· Efficient Delivery: 25 days after order confirmation

· Shipping Terms: FOB QINGDAO

· Payment Options: T/T, D/P, and other terms available upon discussion

Frequently Asked Questions

Q: What warranty coverage do you provide for the Dozer Edge-Cutting 4721467?

A: We provide standard warranty coverage for this product. For complete details on warranty terms and conditions, please contact our sales team.

Q: Can we obtain samples for evaluation prior to larger purchases?

A: Sample units are available to verify product quality and equipment compatibility. Please consult with our sales representatives regarding sample availability and ordering process.

Q: Do you offer preferential pricing for bulk purchases?

A: We extend competitive pricing for volume orders. Kindly provide your specific quantity requirements so we can prepare a tailored quotation.

Contact Us

Looking to enhance your equipment performance with our quality products? Our technical team is ready to assist you with:

Professional product recommendations

Detailed technical specifications

Competitive pricing options

Reliable after-sales support

Email: nancy@sunmach.com.cn

Upgrade to SINOBL cutting edges to maintain optimal equipment productivity. Contact us today to receive expert guidance and discover how our products can deliver lasting value for your operations.

_1761269482712_1762482800019.webp)